Micropore ceramic and preparation method and atomizing core thereof

A technology of microporous ceramics and mixtures, applied in the field of ceramic materials, can solve the problems of low strength, restricting the development of microporous ceramic atomizing cores, and low apparent porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

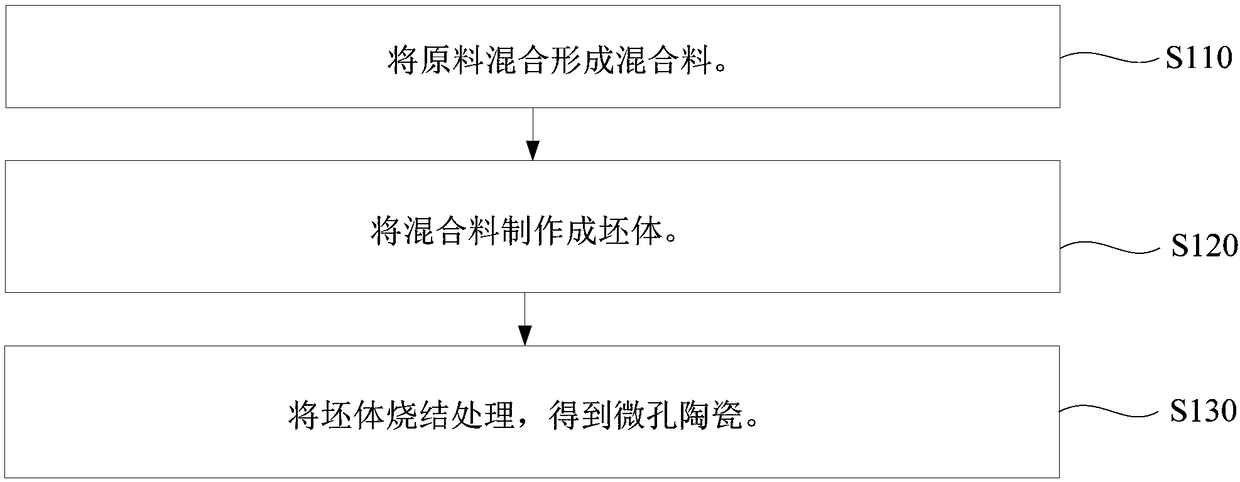

[0023] Such as figure 1 As shown, a method for preparing microporous ceramics according to an embodiment, the microporous ceramics prepared by the preparation method can be used to make an atomizing core of an atomizer. The preparation method of this microporous ceramic comprises the steps:

[0024] Step S110: mixing the raw materials to form a mixture.

[0025] Specifically, the step of mixing raw materials to form a mixture includes: mixing a dispersant, a binder and a solvent to form a premix; mixing the raw materials and the premix to form a slurry; drying the slurry to obtain a mixture.

[0026] Specifically, the dispersant is selected from at least one of sodium citrate, sodium acrylate and sodium stearate. The mass ratio of dispersant to solvent is 0.5:100-3:100.

[0027] Specifically, the binder is selected from at least one of methylcellulose, polyvinyl alcohol and polystyrene. The mass ratio of the binder to the solvent is 0.5:100˜5:100.

[0028] The solvent is ...

Embodiment 1

[0059] The preparation process of the microporous ceramics of the present embodiment is as follows:

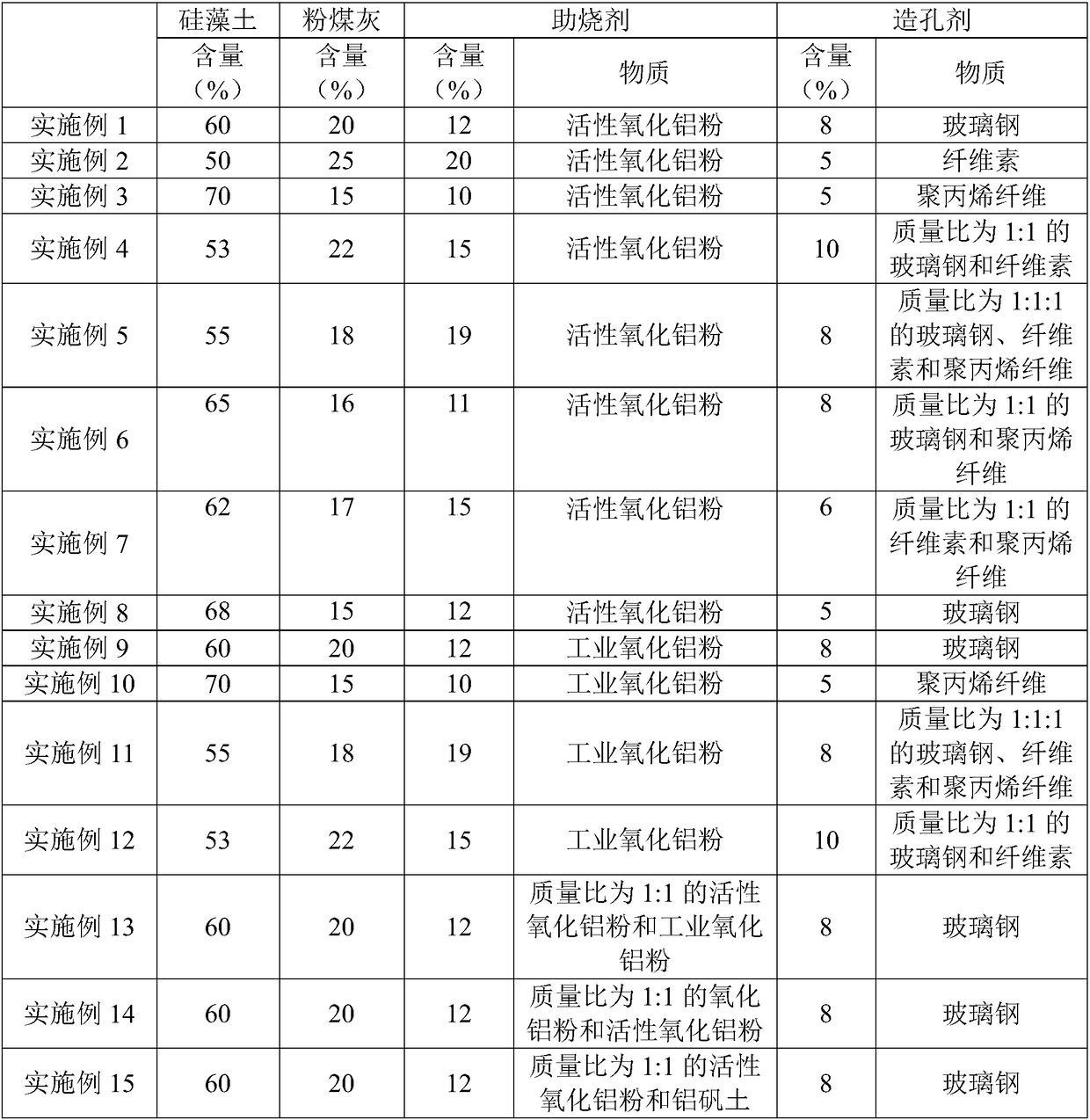

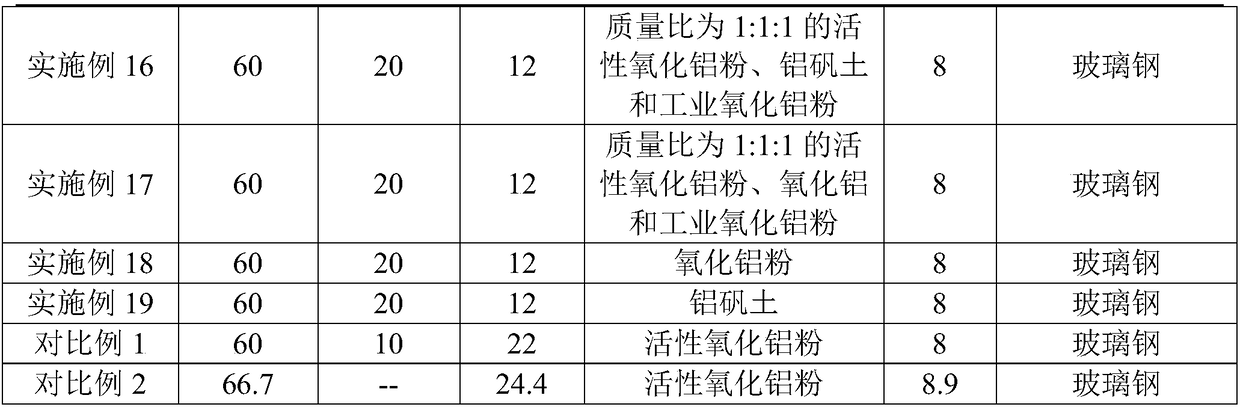

[0060] (1) According to Table 1, each component was weighed according to the mass percentage (referred to as content in the table) to obtain raw materials. Among them, the median particle size of diatomite is 40 microns; the median particle size of fly ash is 40 microns; the median particle size of sintering aid is 25 microns; the median particle size of pore-forming agent is 20 microns.

[0061] (2) Mix the dispersant, binder and distilled water for 1.5 hours to form a premix; mix the raw materials with the premix to form a slurry, and when the ball mill is mixed, the mass ratio of the raw material to the grinding medium is 1:2, The mixing speed was 90 rpm, and the mixing time was 25 hours; the slurry was dried at 85° C. for 15 hours to obtain a mixture. Wherein, the dispersant is sodium citrate; the mass ratio of the dispersant to distilled water is 1.5:100. The binder is ...

Embodiment 2

[0068] The preparation process of the microporous ceramics of the present embodiment is as follows:

[0069] (1) According to Table 1, each component was weighed according to the mass percentage to obtain raw materials. Among them, the median particle size of diatomite is 20 microns; the median particle size of fly ash is 30 microns; the median particle size of sintering aid is 10 microns; the median particle size of pore-forming agent is 10 microns.

[0070] (2) Mix and stir the dispersant, binder and distilled water for 1 hour to form a premix; mix the raw materials with the premix to form a slurry, and when the ball mill is mixed, the mass ratio of the raw material to the grinding medium is 1:2.5, The mixing speed was 60 rpm, and the mixing time was 30 hours; the slurry was dried at 70° C. for 20 hours to obtain a mixture. Wherein, the dispersant is sodium acrylate; the mass ratio of the dispersant to distilled water is 0.5:100; the binder is polyvinyl alcohol; the mass ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com