Waste heat recycling device and method in reaction process of ethene hydroformylation

A technology of ethylene hydroformylation and waste heat recovery device, which is applied in the direction of carbon monoxide reaction preparation, climate change adaptation, chemical industry, etc., can solve the problems of heat waste, heat transfer medium heat cannot be recovered, increase the operating cost of the device, etc., to achieve Improved economy, simple structure, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

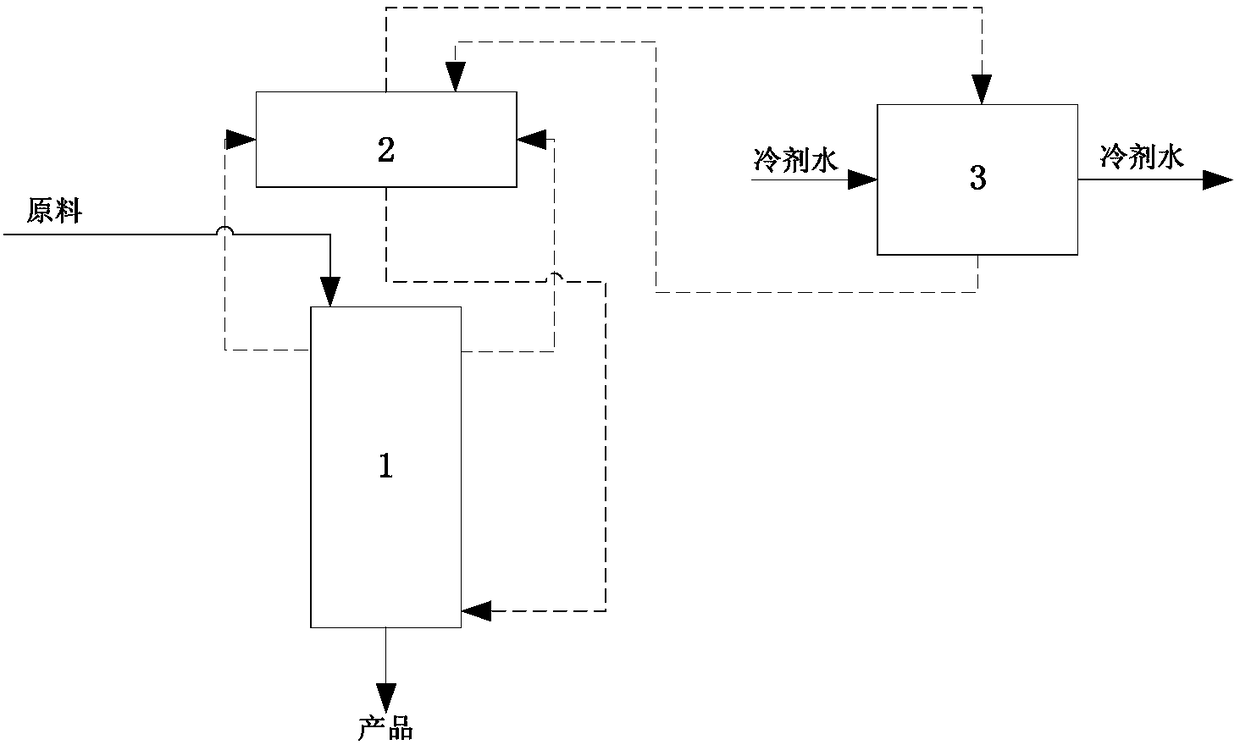

[0032] A waste heat recovery device in the process of ethylene hydroformylation, including reactor 1 (axial reactor, provided with a heat transfer medium outlet), and also includes steam drum 2 (set with a heat transfer medium gas phase inlet) and Refrigeration unit 3 (lithium bromide absorption refrigeration unit), the heat transfer medium outlet of reactor 1 is connected to the heat transfer medium gas phase inlet of steam drum 2, and the heat transfer medium gas phase outlet of steam drum 2 is connected to the heat transfer medium inlet of refrigeration unit 3 , the heat transfer medium liquid phase outlet of steam drum 2 is connected with the heat transfer medium inlet of reactor 1, and the heat transfer medium outlet of refrigeration unit 3 is connected with the heat transfer medium liquid phase inlet of steam drum 2.

[0033] The device is used to recover waste heat in the process of preparing propionaldehyde by ethylene hydroformylation, and the parameters are controlled...

Embodiment 2

[0037]A waste heat recovery device in the process of ethylene hydroformylation, including reactor 1 (radial reactor, provided with two heat transfer medium outlets), and steam drum 2 (set with two heat transfer medium gas phase inlets) ) and refrigeration unit 3 (lithium bromide absorption refrigeration unit), the heat transfer medium outlet of reactor 1 is connected to the heat transfer medium gas phase inlet of steam drum 2, and the heat transfer medium gas phase outlet of steam drum 2 is connected to the heat transfer medium of refrigeration unit 3 The inlet is connected, the heat transfer medium liquid phase outlet of steam drum 2 is connected with the heat transfer medium inlet of reactor 1, and the heat transfer medium outlet of refrigeration unit 3 is connected with the heat transfer medium liquid phase inlet of steam drum 2.

[0038] The device is used to recover waste heat in the process of preparing propionaldehyde by ethylene hydroformylation, and the parameters are ...

Embodiment 3

[0042] A waste heat recovery device in the process of ethylene hydroformylation, comprising a reactor 1 (a radial reactor, provided with three heat transfer medium outlets), and a steam drum 2 (equipped with three heat transfer medium gas phase inlets) and Refrigeration unit 3 (lithium bromide absorption refrigeration unit), the heat transfer medium outlet of reactor 1 is connected to the heat transfer medium gas phase inlet of steam drum 2, and the heat transfer medium gas phase outlet of steam drum 2 is connected to the heat transfer medium inlet of refrigeration unit 3 , the heat transfer medium liquid phase outlet of steam drum 2 is connected with the heat transfer medium inlet of reactor 1, and the heat transfer medium outlet of refrigeration unit 3 is connected with the heat transfer medium liquid phase inlet of steam drum 2.

[0043] The device is used to recover waste heat in the process of preparing propionaldehyde by ethylene hydroformylation, and the parameters are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com