Vinyl terminated polysiloxane containing quaternary ammonium salt, its synthesis and application thereof in preparation of intrinsic quaternary ammonium salt type antibacterial silicone rubber

A vinyl-terminated, chlorohydrocarbyl polysiloxane technology is applied to vinyl-terminated quaternary ammonium salt-containing polysiloxane and its synthesis and application in the preparation of intrinsic quaternary ammonium salt type antibacterial silicone rubber, It can solve the problems of the decline of the mechanical properties of the silicone rubber and the deterioration of the durability of the antibacterial properties of the silicone rubber, and achieve the effects of long-lasting antibacterial properties, long-lasting antibacterial properties and high safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

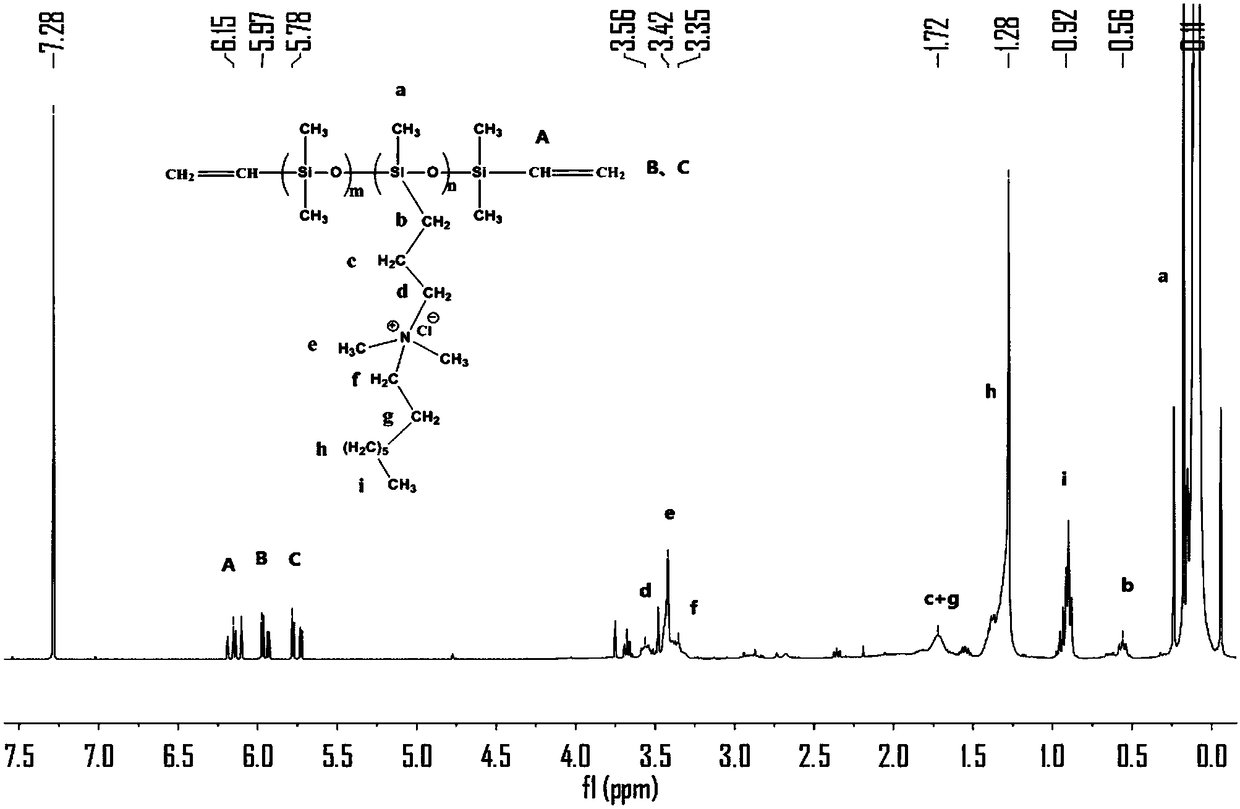

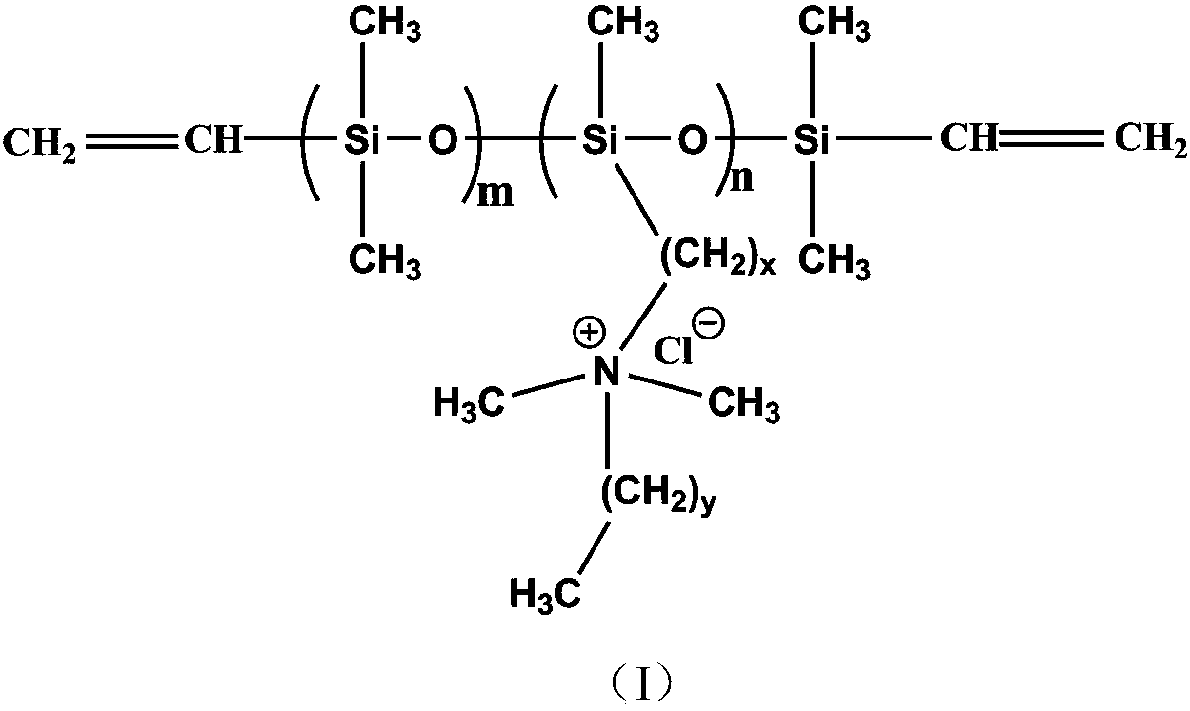

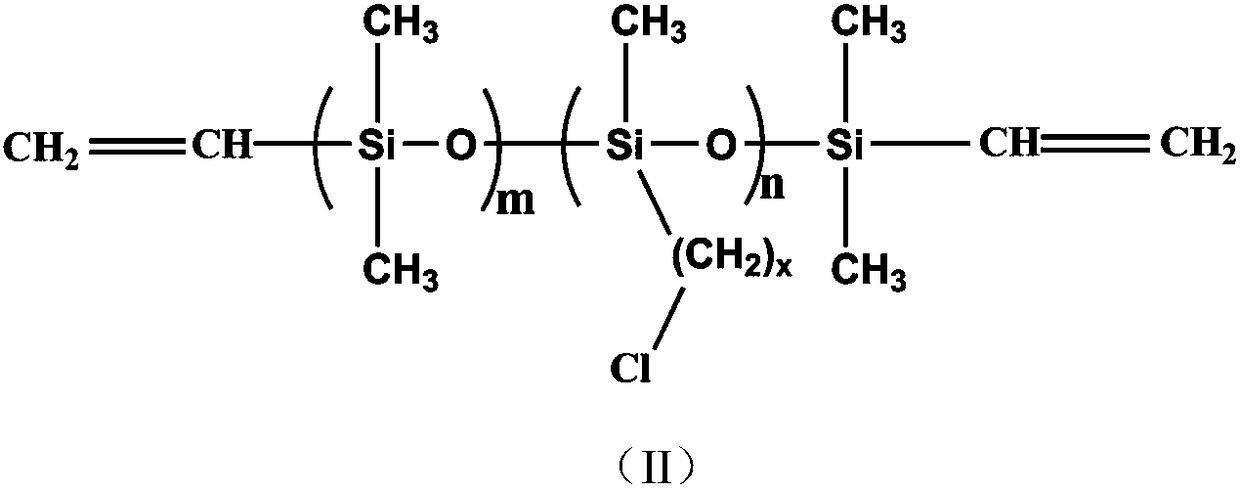

[0035] Add 3.60g D 3 D-C 3 h 6 Cl, 35.97gD 4 , 0.72g tetramethyldivinyl disiloxane, 0.40g Purolite CT-175, stir to mix evenly, slowly raise the temperature to 100°C, react for 10h, and the reaction is completed, cool the system to room temperature, filter to remove the catalyst, The low boilers were distilled off under reduced pressure to obtain a colorless transparent oily liquid, namely vinyl-terminated chloropropyl polysiloxane, with a yield of 96%.

[0036] Dissolve 3.00 g of the obtained vinyl-terminated chloropropyl-containing polysiloxane in 4.50 g of n-butanol, then add 1.51 g of N,N-dimethyl n-octylamine, nitrogen protection, and reflux at 110°C for 72 hours After the reaction, the solvent and unreacted N,N-dimethyl n-octylamine were distilled off under reduced pressure to obtain vinyl-terminated quaternary ammonium salt-containing polysiloxane with a yield of 85%.

Embodiment 2

[0038]Add 3.60g D 3 D-C 3 h 6 Cl, 35.97g D 4 , 0.72g tetramethyldivinyldisiloxane, 0.40g tetramethylammonium hydroxide silicon alkoxide, stir to mix evenly, slowly raise the temperature to 70°C for 0.5h, then raise the temperature to 100°C, react for 10h, The temperature of the system was raised to 130° C. and kept for 0.5 h, and then the low boilers were distilled off under reduced pressure to obtain a colorless transparent oily liquid, namely vinyl-terminated chloropropyl polysiloxane, with a yield of 95%.

[0039] The preparation of vinyl-terminated quaternary ammonium salt-containing polysiloxane is as described in Example 1.

Embodiment 3

[0041] As described in Example 1, the difference is to change the two raw material rings D 3 D-C 3 h 6 Cl and D 4 The component distribution ratio, namely 4.80gD 3 D-C 3 h 6 Cl, 32.58g D 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com