Preparation method for self-cleaning polyurethane elastomer film

A polyurethane elasticity and self-cleaning technology is applied in the field of preparation of self-cleaning polyurethane elastomer films, which can solve the problems of poor application experience, restricting popularization and application, affecting aesthetics, etc., so as to improve the surface self-cleaning function and the process is simple. , The effect of not easy to fall ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Mix TPU powder and polydodecafluoroheptyl methacrylate in a mixer at high speed for 5 minutes, and the mass ratio of TPU to polydodecafluoroheptyl methacrylate is 10:1.

[0020] 2) The molecular weight of polydodecafluoroheptyl methacrylate used in step 1 is 1×10 3 .

[0021] 3) Put the mixture obtained in step 1 into a screw machine to extrude and cast to form a film. The temperature range of the screw is 60°C-180°C, and the temperature of the roller of the calender is 40°C.

[0022] 4) Place the blended TPU film obtained in step 3 in an environment of 40°C for 72 hours, and anneal to set it.

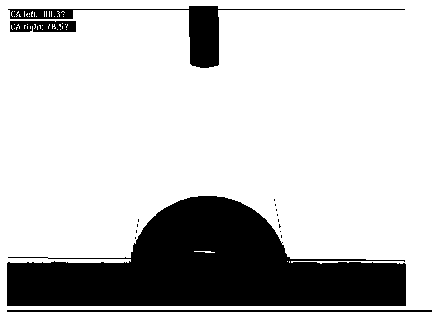

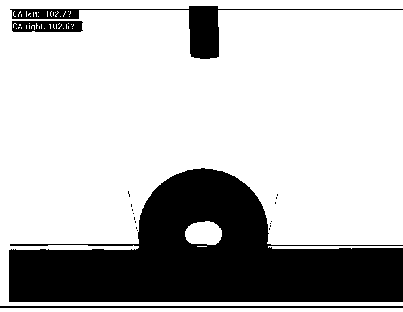

[0023] The surface contact angle of the blended modified TPU film prepared in this implementation case is 102°, and it is difficult to write with an oily water pen. The traces can be directly wiped clean with a wet towel. There is no obvious dust on the surface after being placed indoors for 7 days. A small amount of dust can be cleaned directly with water.

[0024] figur...

Embodiment 2

[0027] 1) Put TPU powder and tetrafluoroethylene-perfluoro-n-propyl vinyl ether copolymer in a mixer and mix at high speed for 5 minutes. The mass ratio of TPU to tetrafluoroethylene-perfluoro-n-propyl vinyl ether copolymer is 50: 1.

[0028] 2) The molecular weight of tetrafluoroethylene-perfluoron-propyl vinyl ether copolymer used in step 1 is 1×10 5 .

[0029] 3) Put the mixture obtained in step 1 into a screw machine for extrusion casting to form a film. The temperature range of the screw is 60°C-180°C, and the temperature of the roller of the calender is 80°C.

[0030] 4) Place the blended TPU film obtained in step 3 in an environment of 80°C for 24 hours, and then anneal and set it.

[0031] The surface contact angle of the blended modified TPU film prepared in this implementation case is 95°, which is difficult to write with an oil-based pen, and its traces can be directly wiped clean with a wet towel. There is no obvious dust on the surface after being placed indoo...

Embodiment 3

[0033] 1) Put TPU powder and chlorotrifluoroethylene copolymer in a mixer and mix them at high speed for 5 minutes. The mass ratio of TPU to chlorotrifluoroethylene copolymer is 25:1.

[0034] 2) The molecular weight of the chlorotrifluoroethylene copolymer used in step 1 is 1×10 4 .

[0035] 3) Put the mixture obtained in step 1 into a screw machine for extrusion casting to form a film. The temperature range of the screw is 60°C-180°C, and the temperature of the roller of the calender is 60°C.

[0036] 4) Place the blended TPU film obtained in step 3 in an environment at 60°C for 48 hours, and anneal to set it.

[0037] The surface contact angle of the blended modified TPU film prepared in this implementation case is 97°, which is difficult to write with an oil-based pen, and its traces can be directly wiped clean with a wet towel. There is no obvious dust on the surface after being placed indoors for 7 days, and there is a small amount of dust on the surface after being p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com