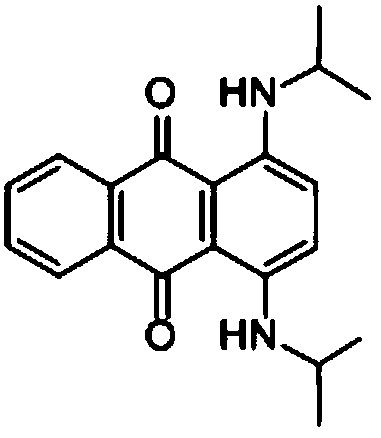

Preparation technology of solvent dye

A preparation process and technology for solvent dyes, applied in anthracene dyes, organic dyes, chemical instruments and methods, etc., can solve the problems of low reaction yield, dark product color, low product purity, etc., and achieve the effect of reducing the difficulty of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

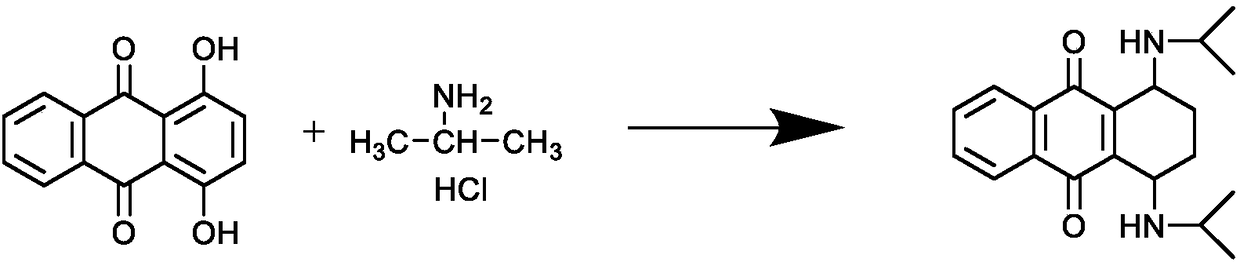

Method used

Image

Examples

Embodiment 1

[0025] In a 500mL four-necked flask equipped with an electric stirrer, 215ml of o-dichlorobenzene, 6.5g of stannous chloride, 100g of 1,4-dihydroxyanthraquinone, and 86g of isopropylamine hydrochloride were put into the reactor, and the temperature was raised to React at 84°C for 10 hours. After the reaction, evaporate part of the o-dichlorobenzene solvent, add 50ml of ethanol and petroleum ether mixed solvent, filter, wash, and dry to obtain 118.86g of the target product. The yield is 88.7%, the purity is 99.2%, the shade DC is 0.51, and the bulk density is 0.60g / cm 3 .

Embodiment 2

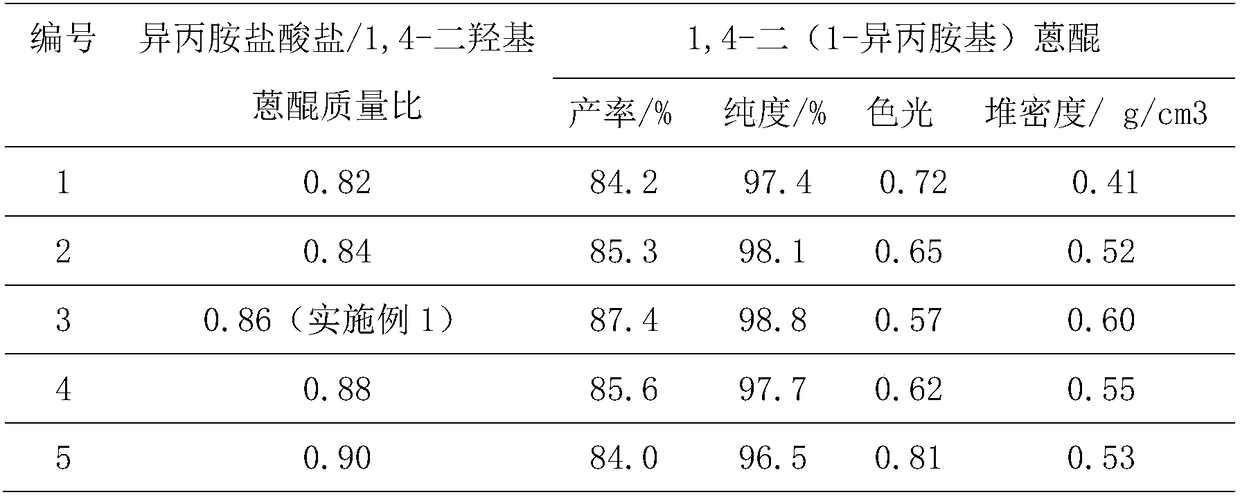

[0027] Other conditions are the same as in Example 1. The experiment of detecting different mass ratios of isopropylamine hydrochloride / 1,4-dihydroxyanthraquinone is shown in Table 1.

[0028] Table 1 Experiments of different mass ratios of isopropylamine hydrochloride / 1,4-dihydroxyanthraquinone

[0029]

[0030] From the above results, it can be known that the mass ratio of isopropylamine hydrochloride / 1,4-dihydroxyanthraquinone is preferably 0.86 (Example 1).

Embodiment 3

[0032] Other conditions are the same as in Example 1, and the experiment of detecting different mass ratios of stannous chloride / 1,4-dihydroxyanthraquinone is shown in Table 2 for the experimental results.

[0033] Table 2 Experiments of different stannous chloride / 1,4-dihydroxyanthraquinone mass ratios

[0034]

[0035] It can be known from the above results that the mass ratio of stannous chloride / 1,4-dihydroxyanthraquinone is preferably 0.065 (Example 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com