Fumet for textile fabric

A technology of textile fabrics and incense agent, which is applied in the field of textile fabrics to achieve the effect of complete essence retention, fresh and elegant fragrance, and good fragrance retention effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

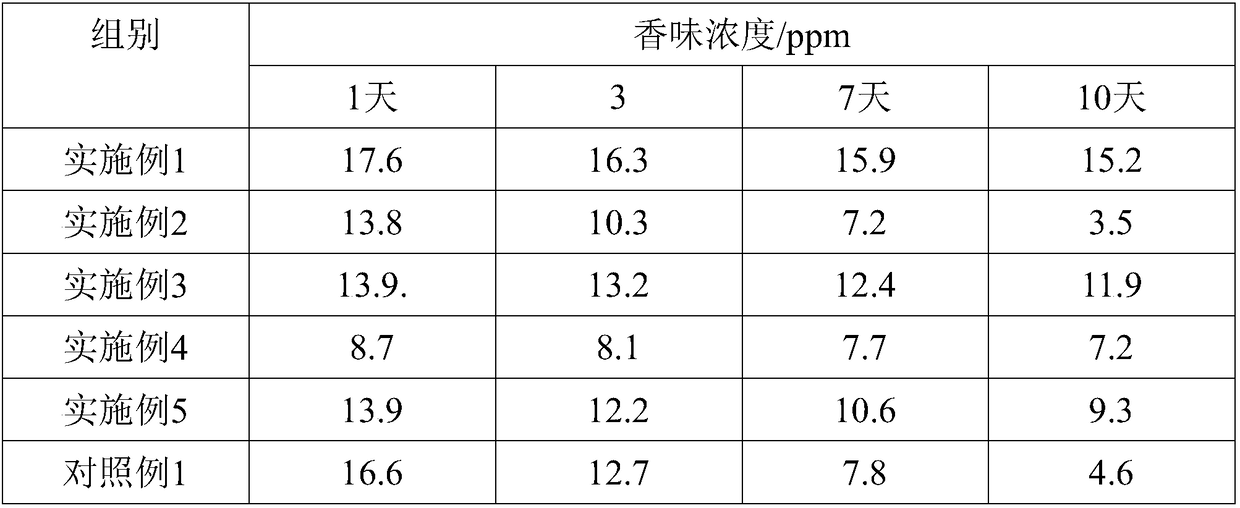

Examples

Embodiment 1

[0022] A fragrance for textile fabrics, made of the following raw materials in parts by weight: 20 parts of essence, 40 parts of silicon dioxide, 10 parts of microcrystalline cellulose, 30 parts of alcohol, 5 parts of hydrogenated palm oil, isopropyl 4 parts of alcohol, 2 parts of chitosan, 5 parts of glycerin, 0.8 parts of citric acid, 60 parts of deionized water.

[0023] The described fragrance for textile fabrics, its preparation method comprises the steps:

[0024] (1) Grinding silicon dioxide and microcrystalline cellulose separately to a size of 60um, and mixing them uniformly;

[0025] (2) Drop alcohol into the mixture of silicon dioxide and microcrystalline cellulose, then add essence, after stirring evenly, treat the mixture with a microwave with a frequency of 2450MHz and a power of 700W for 15min to obtain substance I;

[0026] (3) Add deionized water to substance I, stir evenly, then add hydrogenated palm oil, chitosan, isopropanol, and stir for 20 minutes with a...

Embodiment 2

[0029] A fragrance for textile fabrics, made of the following raw materials in parts by weight: 30 parts of aromatic essential oil, 60 parts of nano-silica, 15 parts of nano-microcrystalline cellulose, 40 parts of alcohol, 10 parts of hydrogenated palm oil , 8 parts of isopropanol, 8 parts of chitosan, 6 parts of glycerin, 2 parts of citric acid, 80 parts of deionized water.

[0030] The aromatic essential oil is made of the following raw materials in parts by weight: 80 parts of rose, 40 parts of magnolia, 20 parts of frankincense, 10 parts of Cyperus cyperi, 8 parts of herb, 8 parts of ginger, 10 parts of pomelo peel, 10 parts of lemon peel, eucalyptus Leaves 6 parts.

[0031] The preparation method of the aromatic essential oil comprises the following steps: mixing rose, magnolia, frankincense, Cyperus cyperi, herb, ginger, pomelo peel, lemon peel, and eucalyptus leaves, and adding 2 times the weight fraction into 20% saline and a mixture of 8% acetic acid, the mixture was...

Embodiment 3

[0037] A fragrance for textile fabrics, made of the following raw materials in parts by weight: 25 parts of aromatic essential oil, 50 parts of silicon dioxide, 13 parts of microcrystalline cellulose, 35 parts of alcohol, 8 parts of hydrogenated palm oil, iso 6 parts of propanol, 5 parts of chitosan, 5 parts of glycerin, 1.5 parts of citric acid, 70 parts of deionized water.

[0038] The aromatic essential oil is made of the following raw materials in parts by weight: 60 parts of rose, 30 parts of magnolia, 18 parts of frankincense, 8 parts of Cyperus cyperi, 5 parts of herb, 5 parts of ginger, 8 parts of grapefruit peel, 8 parts of lemon peel, eucalyptus Leaves 5 parts.

[0039] The preparation method of the aromatic essential oil comprises the following steps: mixing rose, magnolia, frankincense, Cyperus cyperi, herb, ginger, pomelo peel, lemon peel, and eucalyptus leaves, and putting them into 2 times the weight fraction of saline with a concentration of 15% and acetic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com