A dry gas sealing device suitable for supercritical working fluid

A dry gas sealing, supercritical technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of increasing the risk of seal failure, high supercritical working fluid parameters, and increased temperature of the sealing ring to reduce leakage. The effect of reducing the bearing wear, reducing the temperature of the end face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings. However, it should not be understood that the scope of the above-mentioned subject matter of the present invention is limited only to the following content. Without departing from the above idea of the present invention, various replacements or changes made according to common technical knowledge and customary means in this field shall be included in the scope of the present invention.

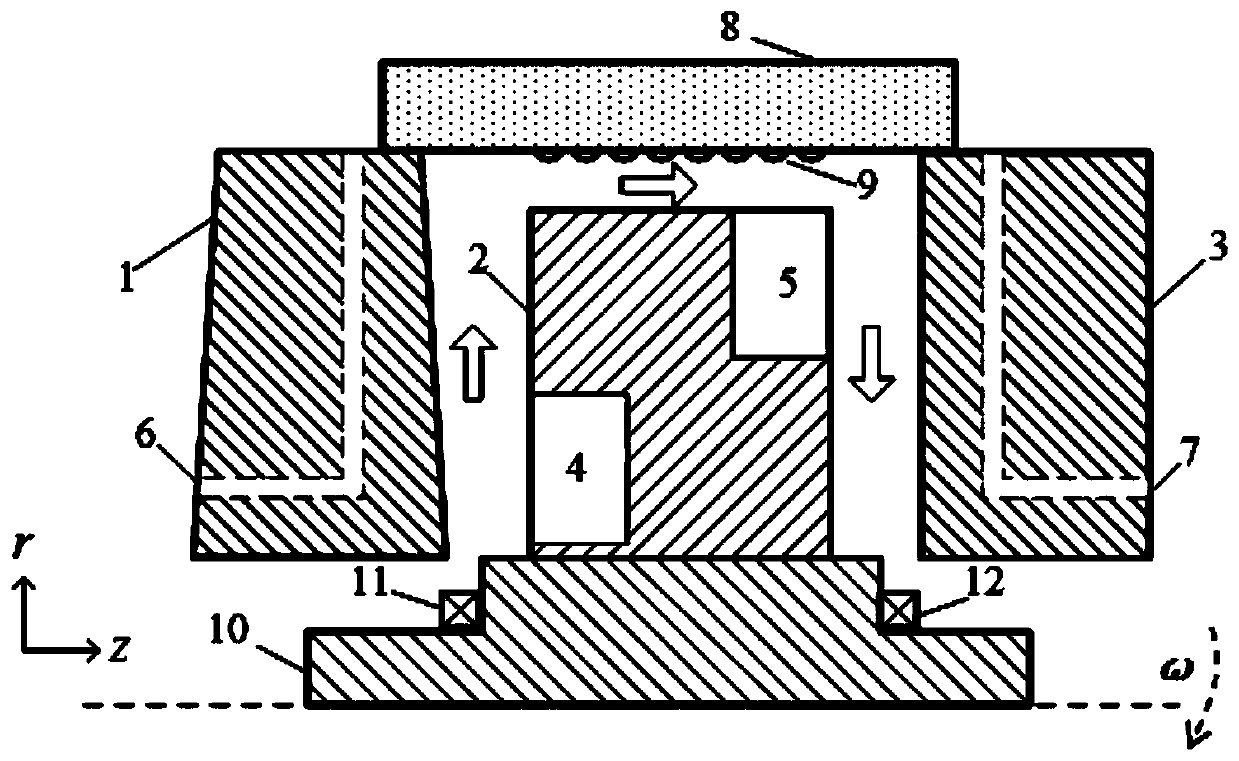

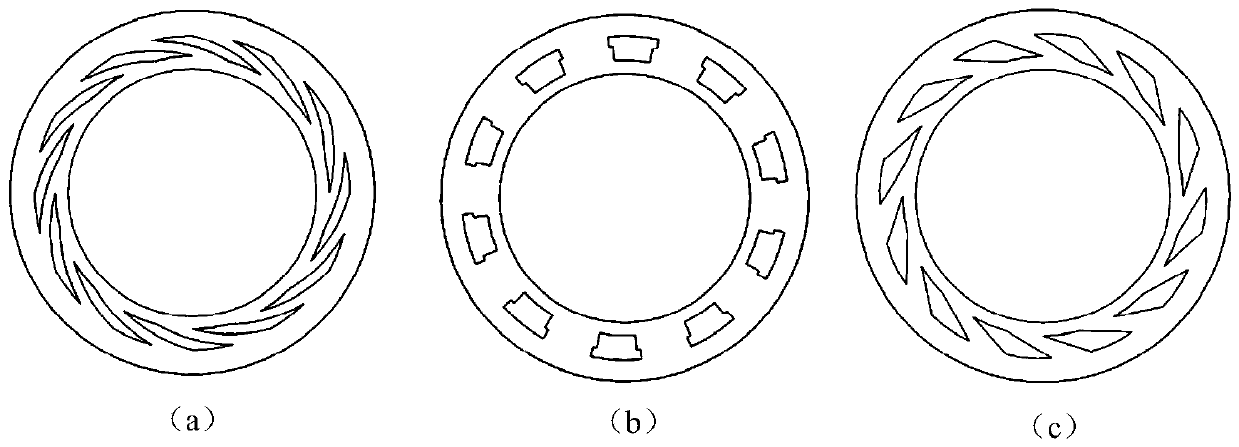

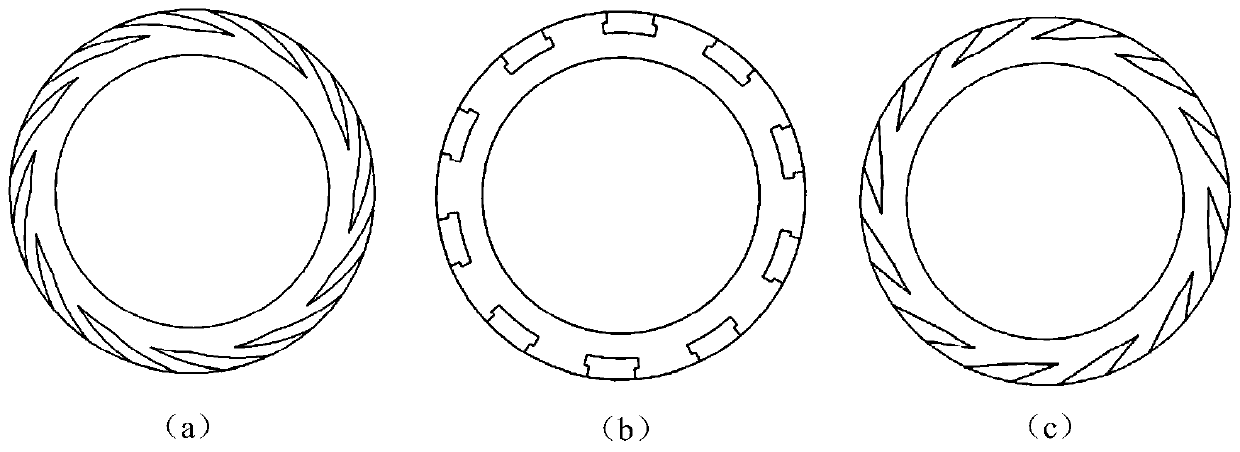

[0034] see figure 1, a dry gas sealing device suitable for supercritical working fluid according to the present invention, comprising a first static ring 1, a moving ring 2, a second static ring 3, a slot 4 on the end surface of the inlet side of the moving ring, and an opening on the end surface of the gas outlet side of the moving ring Groove 5 , first static ring cooling channel 6 , second static ring cooling channel 7 , chamber wall 8 , enhanced heat exchange structure 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com