Separation method of submicron microplastic at water environment or in marine products

A submicron-level separation method technology, applied in the field of submicron-level microplastic separation, can solve the problems of incomplete separation of plastics and interference in real sample analysis, and achieve less loss of plastic particles, low cost, and easy acquisition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Separation of microplastics in seafood prawns

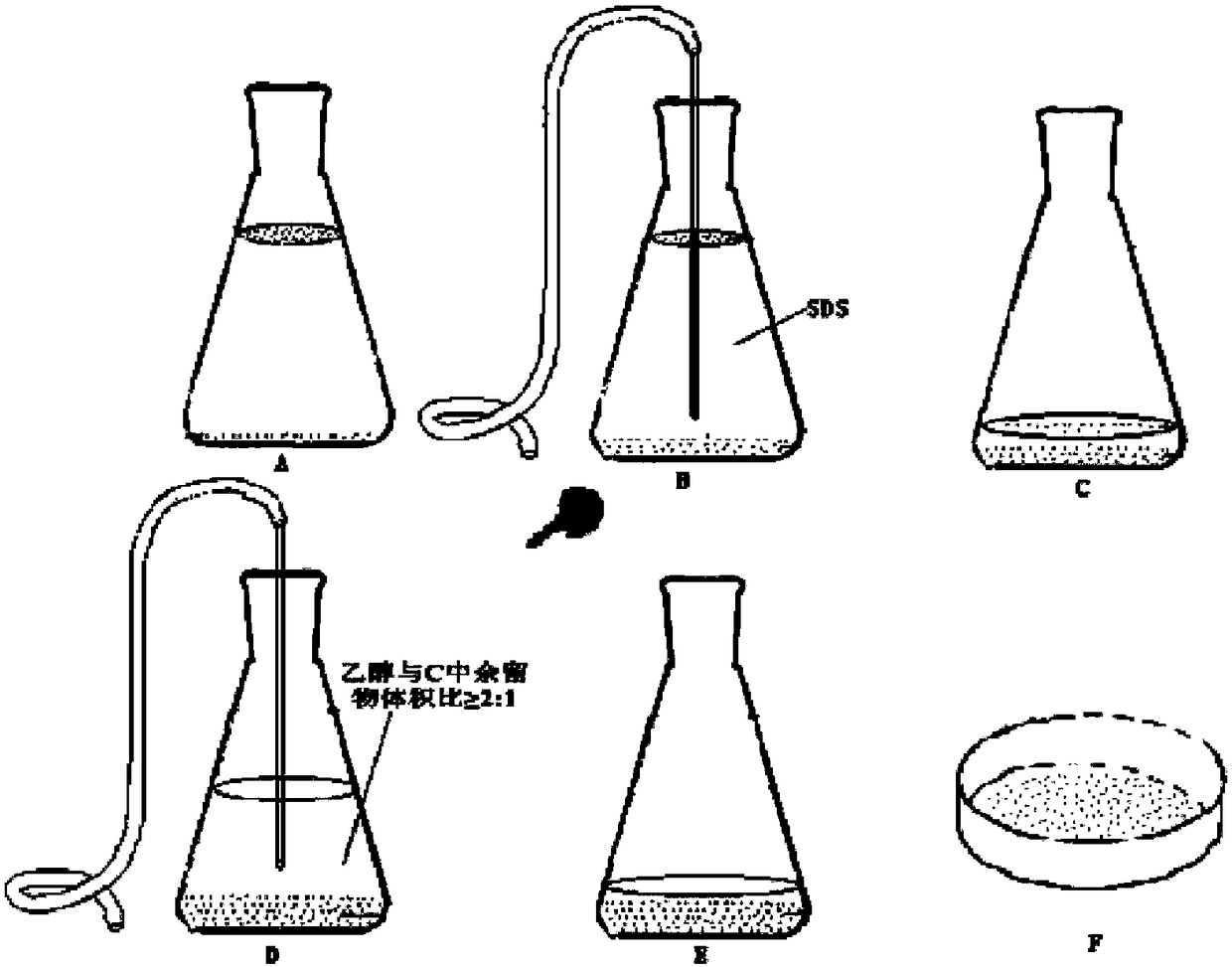

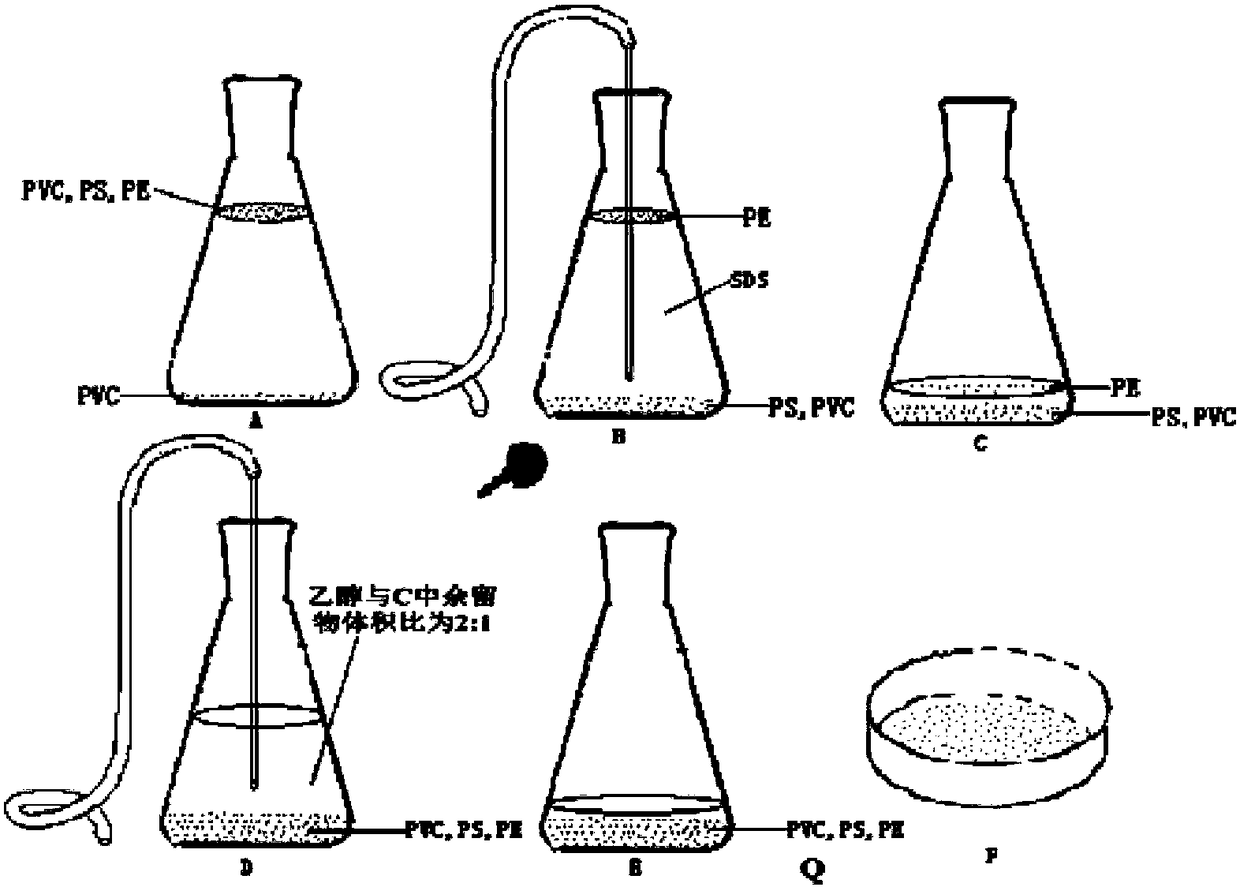

[0031] (1) Weigh 0.336g of freeze-dried prawns in a beaker, add 0.0286g of microplastic standard PVC with a particle size of less than 20μm in the prawns as an internal standard, then add 8mL of nitric acid into the beaker, and then place the beaker Heat on a heating plate at 50°C for 20 minutes, remove the beaker to cool, add 1 mL of hydrogen peroxide, and digest under the same conditions for 15 minutes. After the sample is completely digested, remove the beaker, cool to room temperature, and add 150 mL of water to the reaction solution. Dilute to obtain a digest solution.

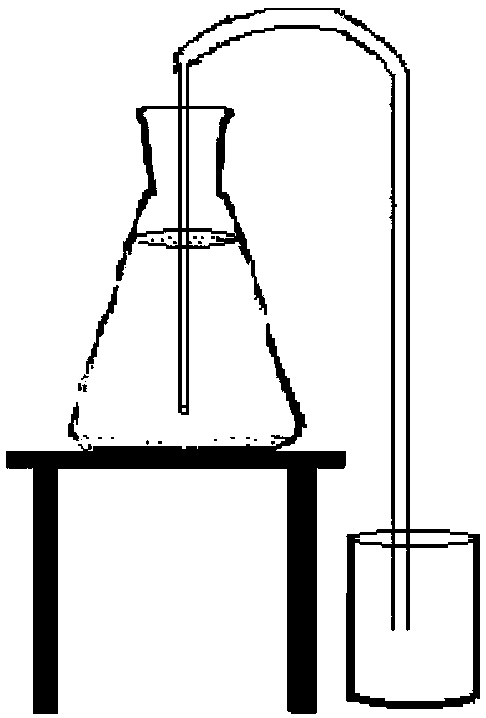

[0032] (2) Add 0.05g sodium lauryl sulfate to the obtained digestion solution (159mL), disperse evenly by ultrasonic (70Hz, 1-2min), let stand for 15min and then divide into suspension layer, solution layer and precipitation layer from top to bottom 3 layers, remove the middle solution layer by siphon, and collect the residue; after taking ...

Embodiment 2

[0042] Example 2 Separation of Microplastics in Water Environment

[0043] Taking the water sample from the Shangtang River in Hangzhou, Zhejiang as the test sample, the separation process is as follows:

[0044](1) Take a 150mL water sample, add 0.031g of microplastic standard PVC with a particle size of less than 20μm as an internal standard in the water sample, then add 0.04g of sodium lauryl sulfate, and disperse evenly by ultrasonic (70Hz, 1-2min) After standing for 15 minutes, it is divided into three layers from top to bottom: suspension layer, solution layer and precipitation layer. Remove the middle solution layer by siphon and collect the residue; take the middle solution layer sucked by siphon and let it stand for 15 minutes. And the bottom is divided into 3 layers, continue to remove the middle layer by siphon, and merge the residue with the previous collection;

[0045] When removing the middle solution layer by siphon, be careful not to remove it completely, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com