Ion chromatograph and its sampling method

An ion chromatograph and sample injection technology, applied in the display field, can solve the problems of clogging ion chromatographic column, ion chromatographic column oxidation failure, detection limit and other problems, and achieve the effect of improving detection stability and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

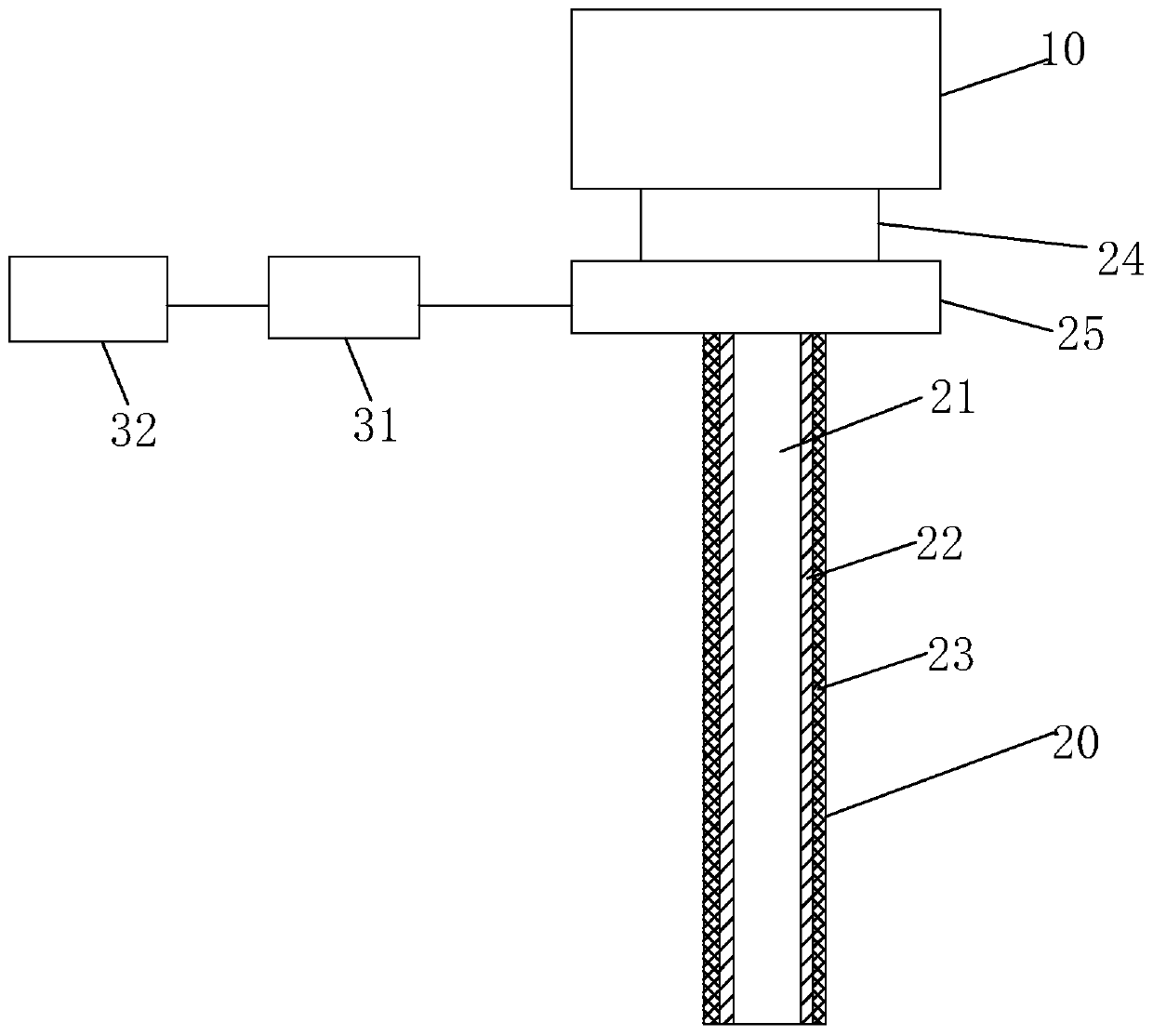

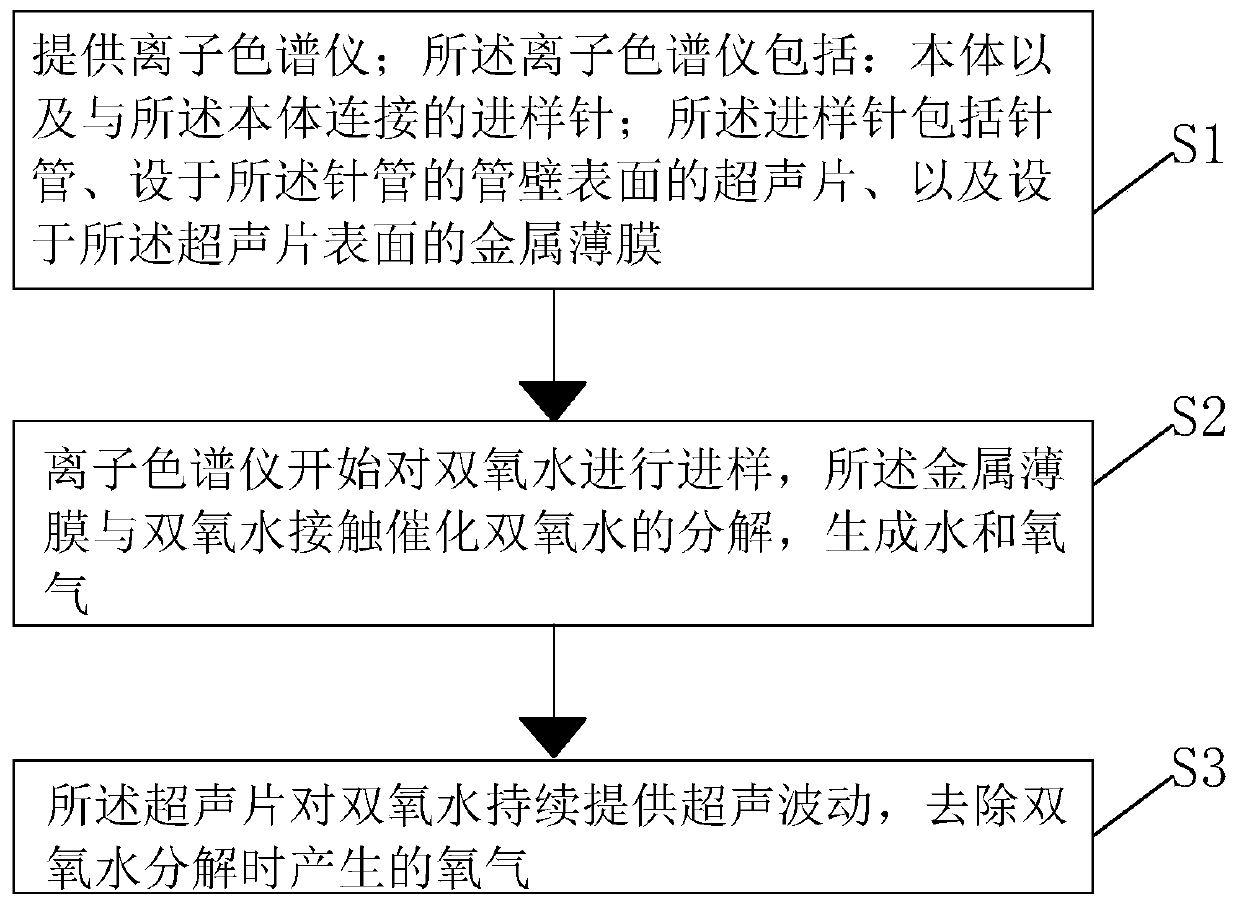

[0028] see figure 1 , The ion chromatograph of the present invention includes: a body 10 and a sampling needle 20 connected to the body 10; the sampling needle 20 includes a needle tube 21, an ultrasonic sheet 22 arranged on the wall surface of the needle tube 21, and The metal thin film 23 provided on the surface of the ultrasonic sheet 22 .

[0029] It should be noted that the ion chromatograph of the present invention injects hydrogen peroxide through the injection needle 20, and the hydrogen peroxide continuously enters the ion chromatograph through the needle tube 21. During the hydrogen peroxide injection process, the needle tube 21 is soaked in hydrogen peroxide. , the metal film 23 is in direct contact with hydrogen peroxide to cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com