Carbonaceous materials and methods of use thereof

A technology of carbon coating and particles, which is applied in the field of carbon-containing materials and its application, and can solve problems affecting battery parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

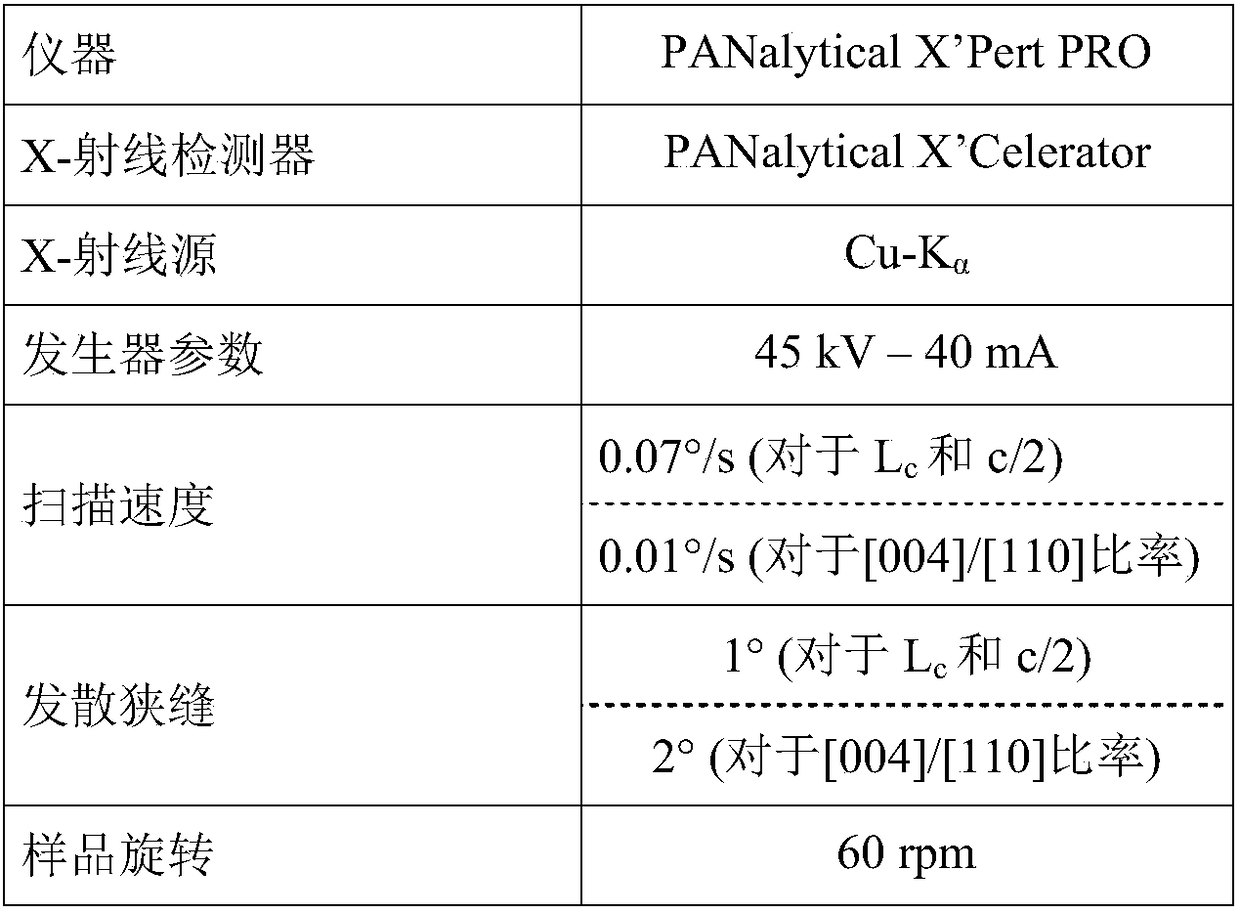

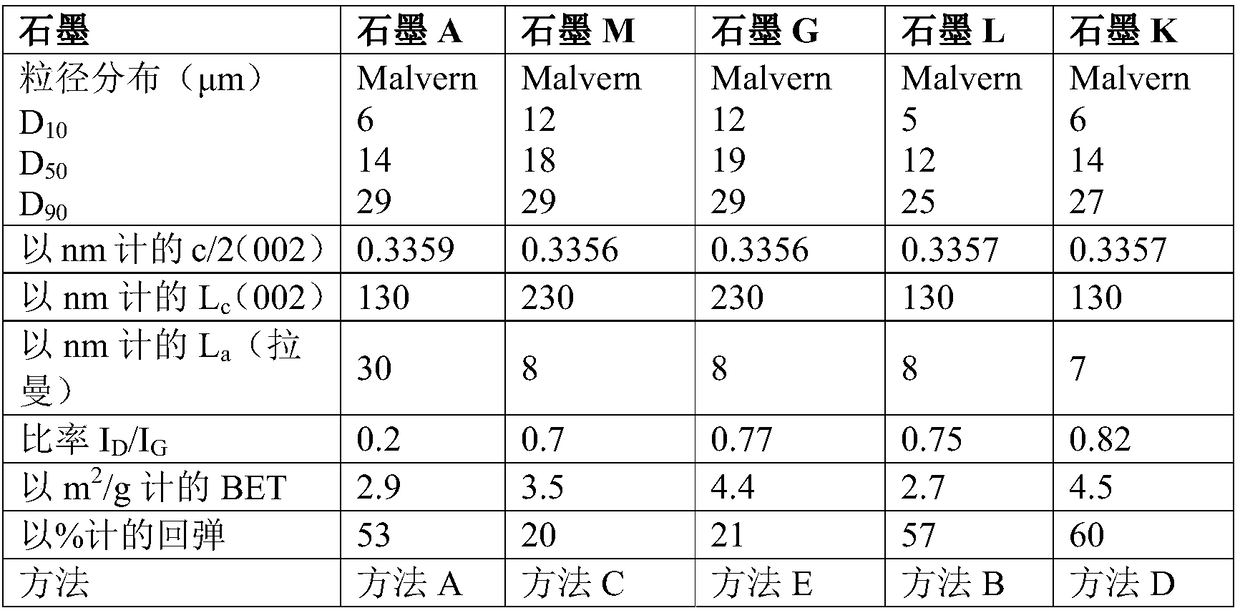

[0176] A number of highly resilient, surface-modified graphite materials were fabricated according to the general methods listed below. Table 2a summarizes the characteristics of these materials (particle size distribution, c / 2, L c , L a , ratio I D / I G , BET SSA and rebound).

[0177] General method for making surface-modified carbonaceous particulate materials

[0178] The following is a general description of how the various carbonaceous materials shown in the examples were obtained.

[0179] Low rebound components:

[0180] Synthetic graphite:

[0181] Petroleum based coke is graphitized at a temperature above 2500°C under an inert gas atmosphere and ground to a suitable particle size distribution.

[0182] Natural flake graphite:

[0183] Chemically or thermally purified natural graphite flakes are ground to the appropriate particle size distribution.

[0184] High resilience components:

[0185] Method A:

example 2

[0205] Following the steps described in Example 1, high resilience graphite (graphite A) was mixed with low resilience graphite as the main component to produce a negative electrode. The specific wt% of high resilience graphite and low resilience graphite employed are given in Table 3. The electrochemical measurements characterizing the obtained graphite anodes are also shown in Table 3.

[0206] Table 3: Reversible capacity and cycle stability characterization of anodes produced using exemplary graphite compositions

[0207] main graphite components

[0208] *Capacity lost per cycle for 2nd - 12th charging cycle

example 3

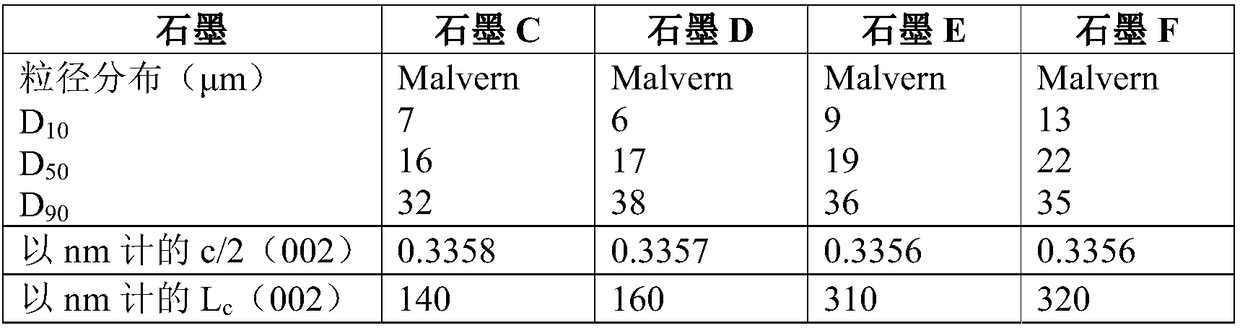

[0211] According to the steps described in Example 1, another high resilience graphite (graphite C) was mixed with low resilience graphite as a main component to produce a graphite negative electrode. The specific wt% of high resilience graphite and low resilience graphite employed are given in Table 4. The electrochemical measurements characterizing the obtained graphite anodes are also shown in Table 4.

[0212] Table 4: Electrode resistance, reversible capacity, high current rate performance characterization of various graphite anodes produced using exemplary graphite compositions

[0213]

[0214] * Comparative example

[0215] As shown in Table 4, the low resilience graphite material was found to reduce electrode resistance at relatively low amounts, but resulted in increased resistance at higher amounts. However, increasing the amount of low-rebound graphite material leads to a continuous increase in the reversible capacity of the electrode. This indicates that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com