Industrial waste gas purification device using novel waste gas absorbent

A technology for purification device and industrial waste gas, applied in inorganic chemistry, gas treatment, alkali metal compounds, etc., can solve the problems of poor adsorption effect and low work efficiency, and achieve the effect of low production cost, excellent adsorption performance and good adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

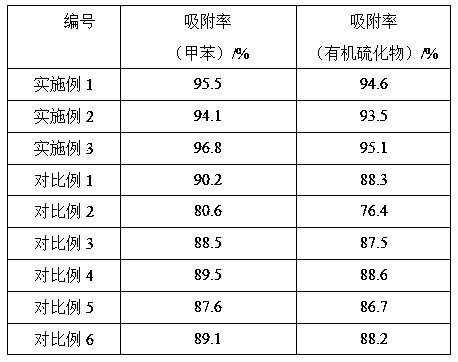

Examples

Embodiment 1

[0019] An industrial waste gas purification device using a new type of waste gas adsorbent. The purification device includes an adsorption tower and a packed tower. The lower part of the packed tower is provided with a waste gas inlet and a liquid outlet pipe, and the upper part is provided with a purified gas outlet. The top is provided with a liquid inlet pipe; the outlet of the adsorption tower is connected to one end of the waste gas inlet, so that the waste gas discharged from the adsorption tower enters the packed tower through the waste gas inlet; There is at least one layer of baffles inside the tower, and circular through holes are arranged on the baffles, and packing rings with biofilms are stacked on each layer of baffles to form a packing layer; the ends of the liquid inlet pipes are fixedly connected There are nozzles to evenly spray the liquid from the upper part of the packed tower to the packed ring, and the adsorption tower is filled with a new exhaust gas adso...

Embodiment 2

[0025] An industrial waste gas purification device using a new type of waste gas adsorbent. The purification device includes an adsorption tower and a packed tower. The lower part of the packed tower is provided with a waste gas inlet and a liquid outlet pipe, and the upper part is provided with a purified gas outlet. The top is provided with a liquid inlet pipe; the outlet of the adsorption tower is connected to one end of the waste gas inlet, so that the waste gas discharged from the adsorption tower enters the packed tower through the waste gas inlet; There is at least one layer of baffles inside the tower, and circular through holes are arranged on the baffles, and packing rings with biofilms are stacked on each layer of baffles to form a packing layer; the ends of the liquid inlet pipes are fixedly connected There are nozzles to evenly spray the liquid from the upper part of the packed tower to the packed ring, and the adsorption tower is filled with a new exhaust gas adso...

Embodiment 3

[0031]An industrial waste gas purification device using a new type of waste gas adsorbent. The purification device includes an adsorption tower and a packed tower. The lower part of the packed tower is provided with a waste gas inlet and a liquid outlet pipe, and the upper part is provided with a purified gas outlet. The top is provided with a liquid inlet pipe; the outlet of the adsorption tower is connected to one end of the waste gas inlet, so that the waste gas discharged from the adsorption tower enters the packed tower through the waste gas inlet; There is at least one layer of baffles inside the tower, and circular through holes are arranged on the baffles, and packing rings with biofilms are stacked on each layer of baffles to form a packing layer; the ends of the liquid inlet pipes are fixedly connected There are nozzles to evenly spray the liquid from the upper part of the packed tower to the packed ring, and the adsorption tower is filled with a new exhaust gas adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com