A method for preparing environmentally friendly permeable bricks from recycled materials from construction waste

A technology for construction waste and seepage bricks, applied in sustainable waste treatment, solid waste management, climate sustainability, etc. Problems such as large consumption of water and water reducing agent, high water absorption of recycled materials, etc., to enhance water reducing effect, increase water reducing dosage, and promote adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

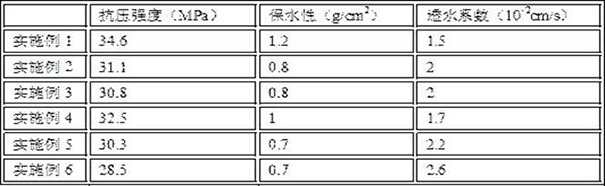

Examples

Embodiment 1

[0029] A method for preparing environmentally friendly permeable bricks from recycled construction waste materials, comprising the following steps:

[0030] (1) Preparation of cementitious base material and wetting base material: Stir 15 parts of cement and 0.5 part of water reducing agent evenly, add 5 parts of fly ash and mix to prepare cementitious base material; mix 40 parts of recycled fine aggregate and Stir 30 parts of recycled sand evenly, add 5 parts of water, and mix to obtain a wet base material;

[0031] (2) Prepare the concrete base material: mix the gel base material and the wet base material in step (1), stir for 15 minutes, add 8 parts of water, and stir for another 20 minutes to obtain the concrete base material, which is set aside;

[0032] (3) Preparation of cementitious surface material and wetting surface material: Stir 20 parts of cement and 0.8 parts of water reducer evenly, add 7 parts of fly ash and mix to obtain a gelled surface material; mix 2 parts ...

Embodiment 2

[0037] A method for preparing environmentally friendly permeable bricks from recycled construction waste materials, comprising the following steps:

[0038] (1) Preparation of cementitious base material and wetting base material: Mix 10 parts of cement and 0.5 part of water reducer evenly, add 3 parts of fly ash to mix to prepare cementitious base material; mix 50 parts of recycled fine aggregate and Stir 30 parts of recycled sand evenly, add 5 parts of water, and mix to obtain a wet base material;

[0039] (2) Prepare the concrete base material: mix the gel base material and the wet base material in step (1), stir for 10 minutes, add 10 parts of water, and stir for another 20 minutes to obtain the concrete base material, which is set aside;

[0040] (3) Preparation of cementitious surface material and wetting surface material: Stir 15 parts of cement and 0.8 parts of water reducer evenly, add 5 parts of fly ash and mix to obtain a gelled surface material; mix 1.5 parts of min...

Embodiment 3

[0045] A method for preparing environmentally friendly permeable bricks from recycled construction waste materials, comprising the following steps:

[0046] (1) Preparation of cementitious base material and wetting base material: Stir 20 parts of cement and 0.8 parts of water reducer evenly, add 8 parts of fly ash and mix to prepare cementitious base material; mix 60 parts of recycled fine aggregate and Stir 30 parts of recycled sand evenly, add 5 parts of water, and mix to obtain a wet base material;

[0047] (2) Prepare the concrete base material: mix the gel base material and the wet base material in step (1), stir for 20 minutes, add 10 parts of water, and stir for another 30 minutes to obtain the concrete base material, which is set aside;

[0048] (3) Preparation of cementitious surface material and wetting surface material: Stir 30 parts of cement and 1 part of water reducer evenly, add 10 parts of fly ash and mix to obtain a gelled surface material; mix 3 parts of mine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com