Concrete-filled steel tube arch bridge construction support system and construction method

A steel pipe concrete and system technology, applied in the direction of arch bridges, bridges, bridge forms, etc., can solve the problems of large self-stability, inconvenient construction, self-heaviness, etc., and achieve the effect of shortening the construction period, saving construction period, and easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

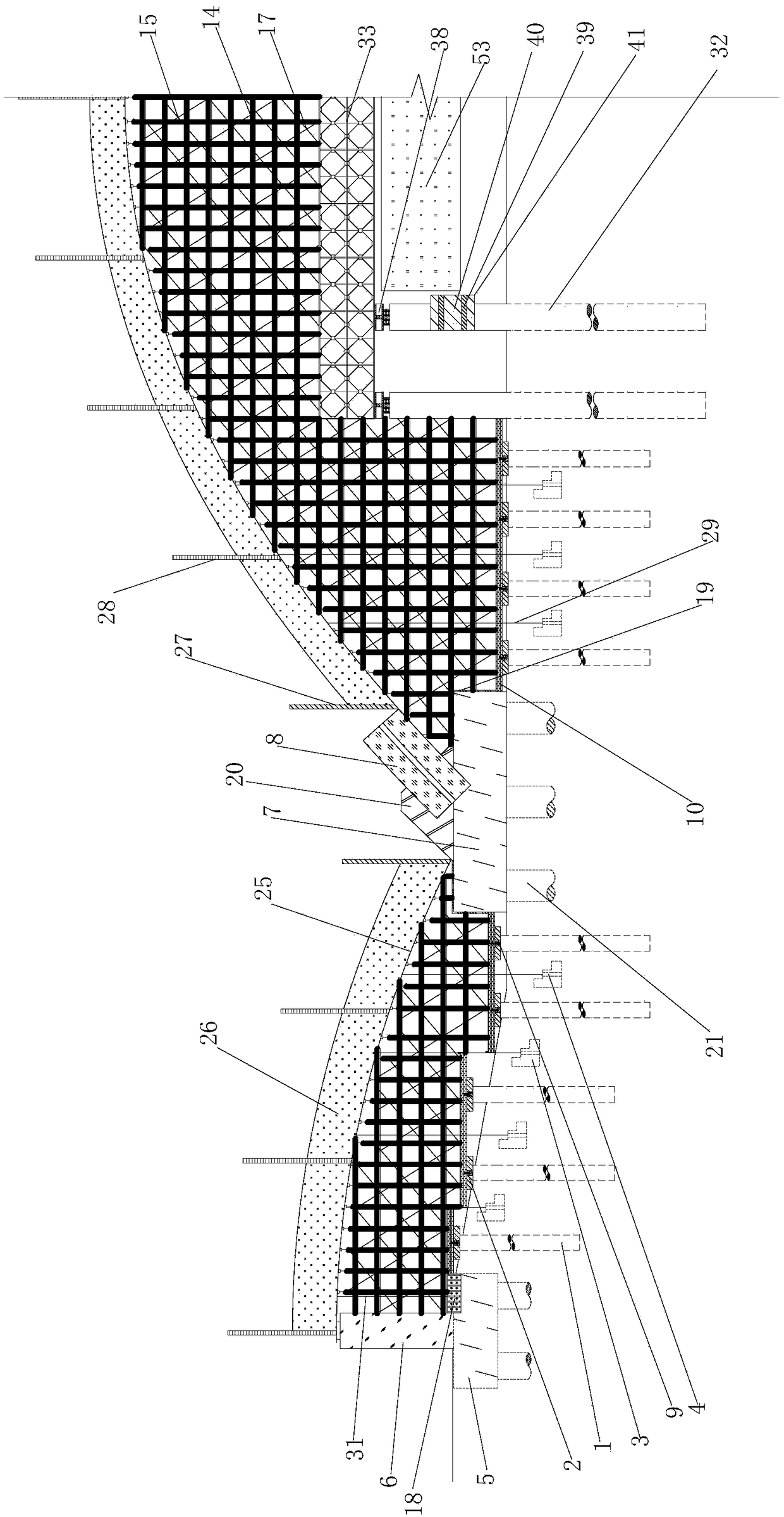

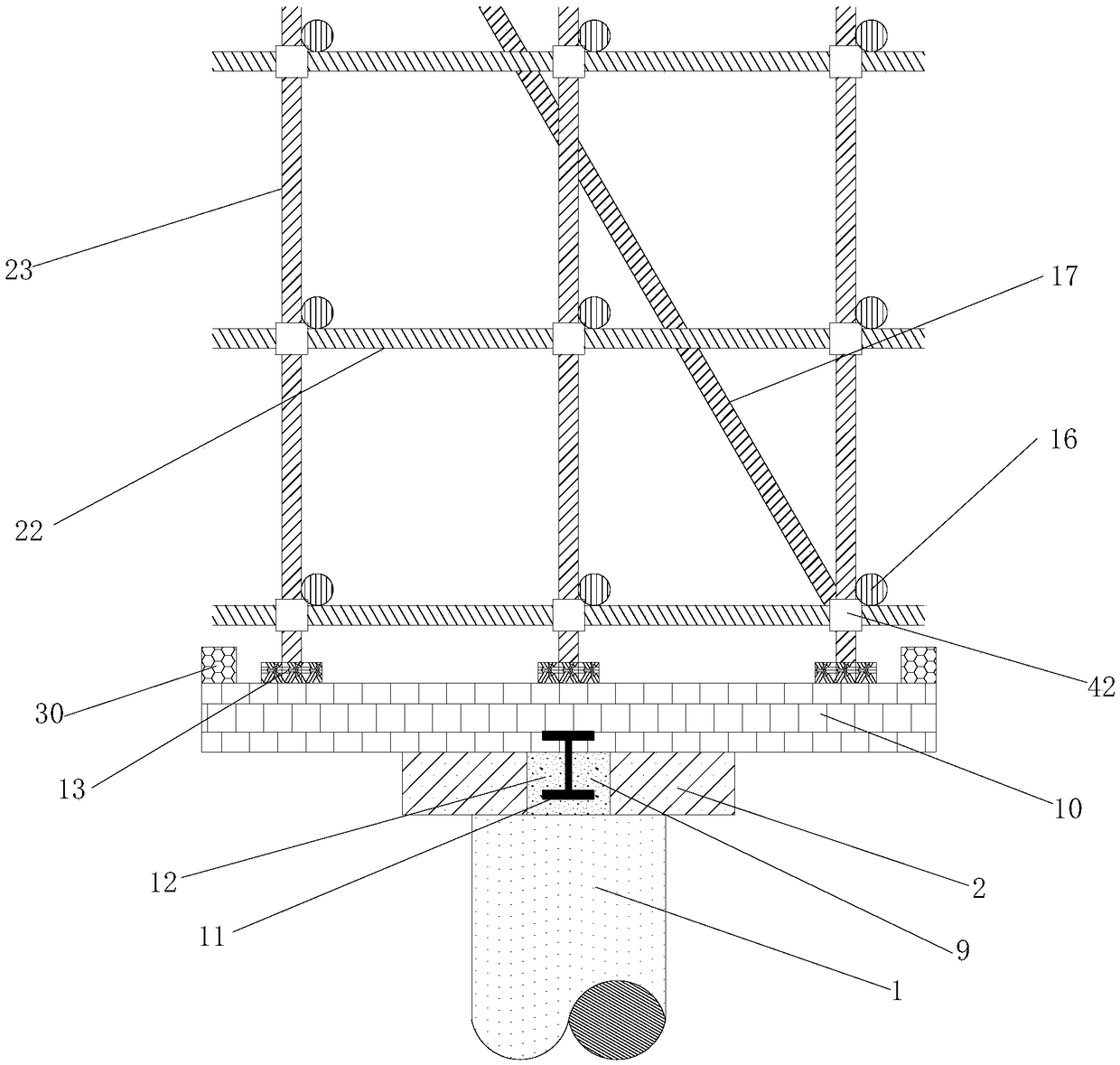

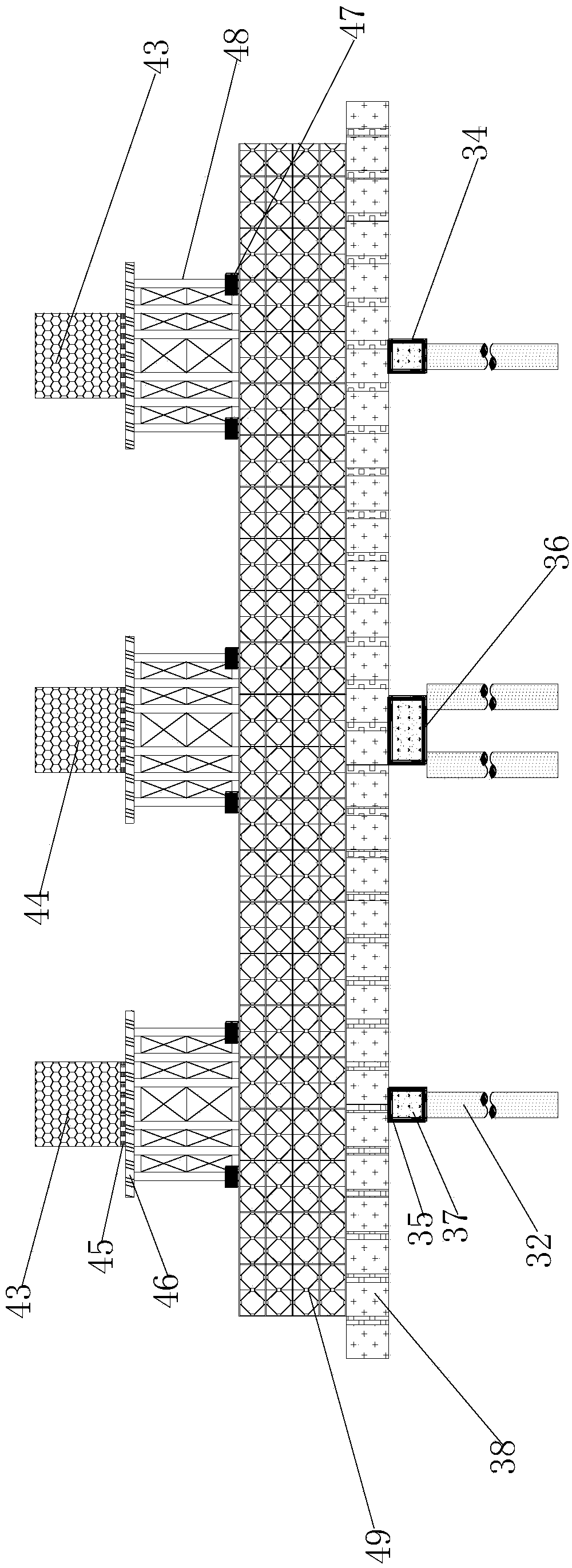

[0033] Such as figure 1The installation diagram of the concrete-filled steel tube arch bridge support system mainly includes: foundation treatment pile 1, shallow solidified cement-soil slab 2, prefabricated step anchor cable frame anchoring bottom beam 3, anchor cable pre-buried section 4, side pier cap 5. Side pier pier body 6, main pier cap 7, main arch rib arch foot steel pipe 8, reserved anchor hole 9, frame frame support bottom plate 10, unit scaffold truss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com