Prefabricated hybrid structure prefabricated toilet and manufacturing method thereof

A hybrid structure and prefabricated technology, applied in the direction of building structure, building components, special buildings, etc., can solve the problems of inconsistent concrete integrity, soft steel structure, horizontal displacement, etc., to save labor and steel usage Consumption, good anti-leakage performance, guarantee the effect of quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

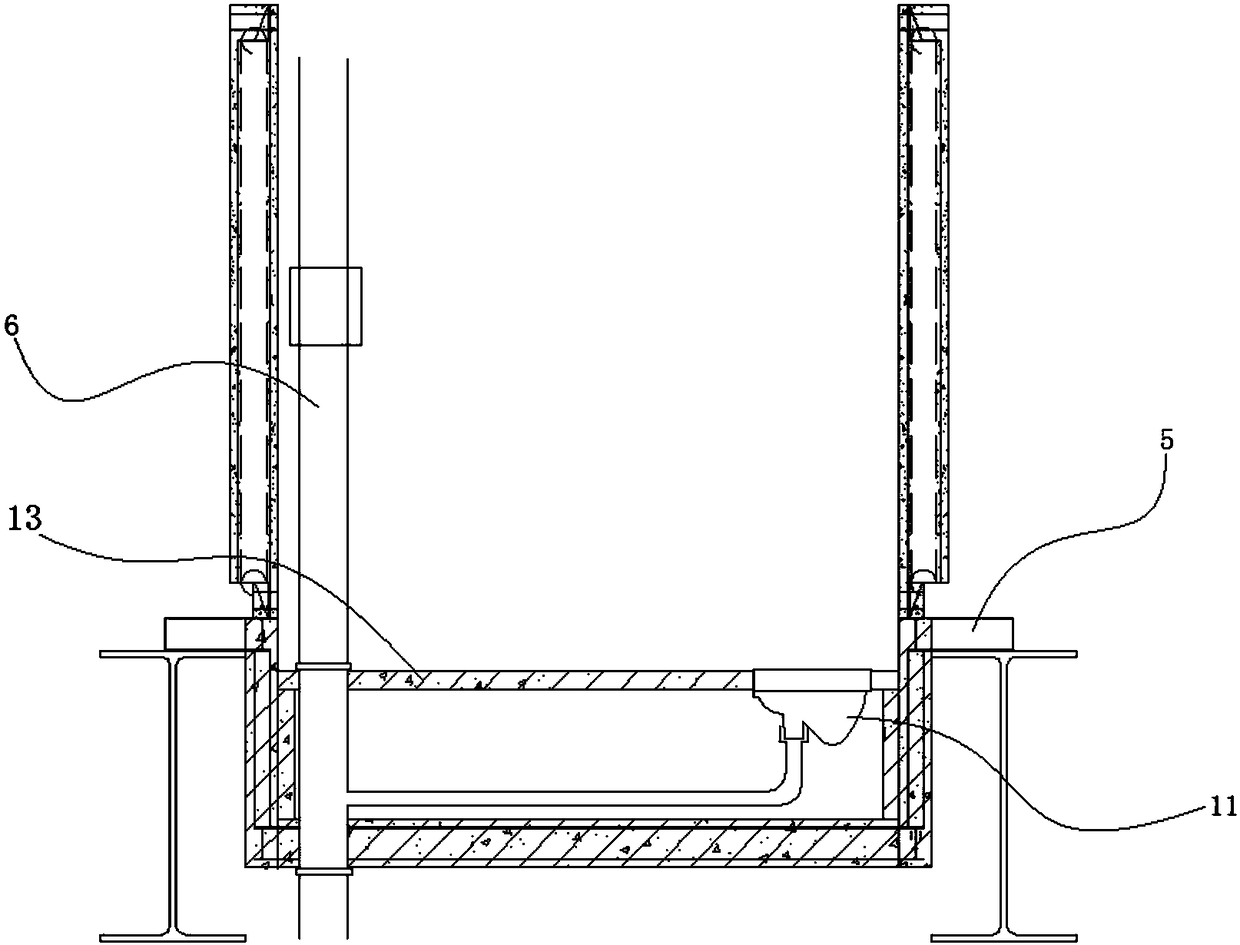

[0059] This embodiment discloses a mixed-structure prefabricated toilet for prefabricated buildings, see figure 1 and figure 2 , floor elements and wall elements fixedly connected to steel beams or composite beams.

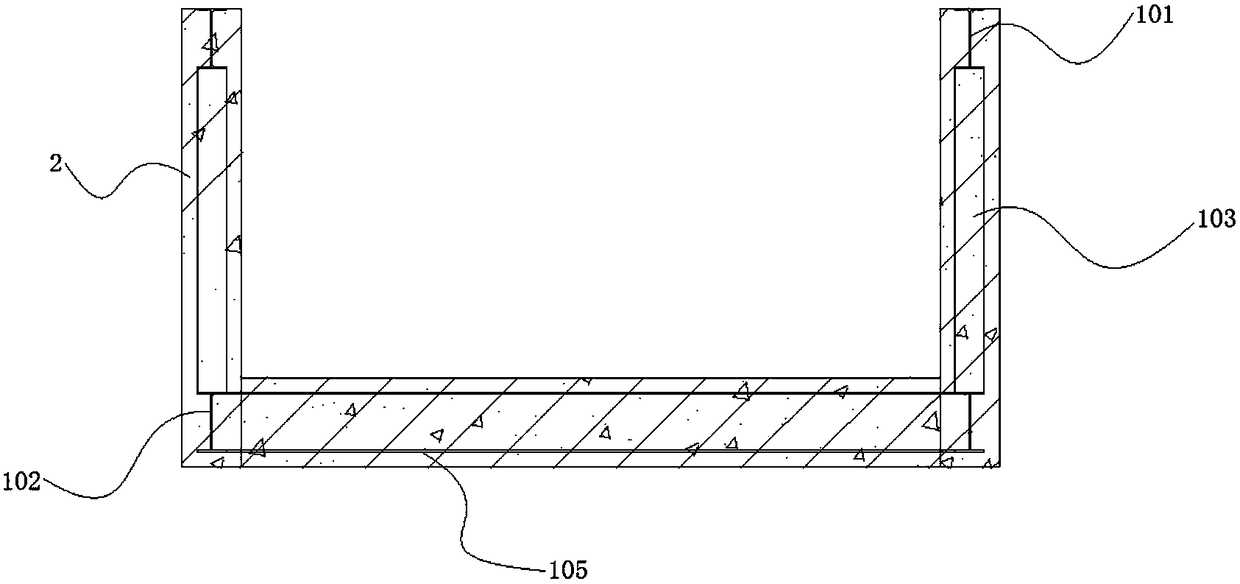

[0060] see image 3 , Figure 4 and Figure 5, the bottom plate unit is a prefabricated steel skeleton concrete sinking groove type prefabricated installation unit. The base plate unit includes a base plate steel skeleton 1 , concrete 2 and a reinforcement mesh 3 . The floor steel framework 1 includes four upper beams 101 , four lower beams 102 , steel framework side vertical bars 103 and floor beams 105 . The four lower side rails 102 are arranged in a rectangular shape. The floor beam 105 is arranged between the two opposite side rails 102 . The four roof beams 101 are arranged in a rectangle, and each roof beam 101 has a protruding part. The protruding part of the roof side beam 101 is provided with a connecting piece I5. The upper side rail 101 is ar...

Embodiment 2

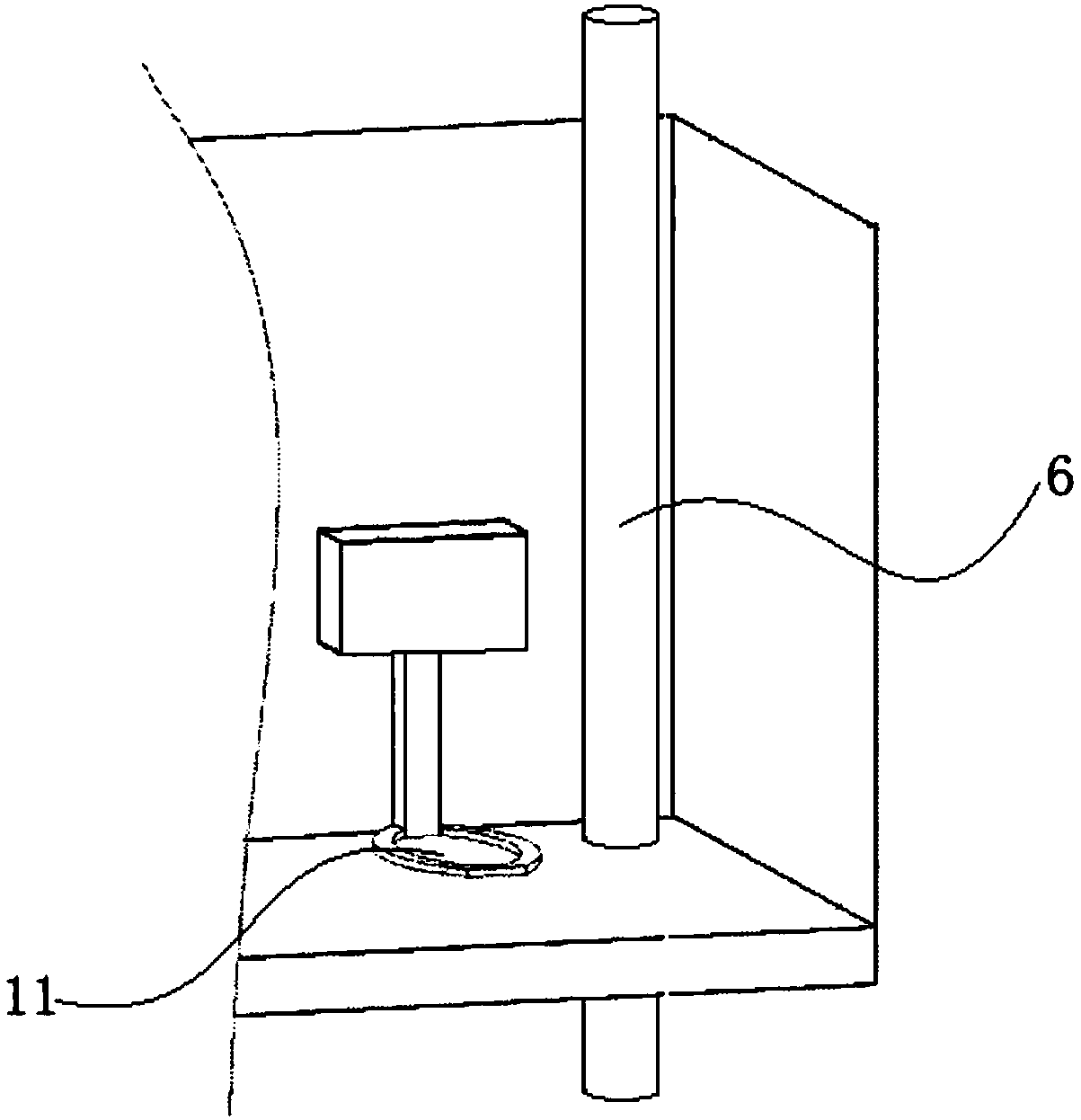

[0064] This embodiment discloses a mixed-structure prefabricated toilet for prefabricated buildings, including a wall unit, a sewage main riser 6, and a floor unit fixedly connected with steel beams or composite beams.

[0065] The base plate unit includes a base plate steel skeleton 1 , concrete 2 and a reinforcement mesh 3 . The floor steel framework 1 includes four upper beams 101 , four lower beams 102 , steel framework side vertical bars 103 and floor beams 105 . The steel used for the base plate steel frame 1 is I-beam, channel steel, angle steel, C-beam, Z-beam or welded H-beam. The four lower side rails 102 are arranged in a rectangular shape. The floor beam 105 is arranged between the two opposite side rails 102 . The four roof beams 101 are arranged in a rectangle, and each roof beam 101 has a protruding part. The protruding part of the roof side beam 101 is provided with a connecting piece I5. The upper side rail 101 is arranged above the lower side rail 102 . ...

Embodiment 3

[0070] This embodiment discloses a method for manufacturing the prefabricated toilet described in Embodiment 1 or 2, comprising the following steps:

[0071] 1) Carry out scheme design as required.

[0072] 2) The floor unit is prefabricated at the factory.

[0073] 2.1) Prefabricated floor steel skeleton 1.

[0074] 2.2) Weld the connecting plate I4 and the connecting piece I5 on the steel frame 1 of the bottom plate.

[0075] 2.3) Arrange the reinforcement mesh 3.

[0076] 2.4) According to the appearance size and function requirements of the floor steel skeleton 1, the steel formwork of the toilet floor unit is produced in batches.

[0077] 2.5) Put the finished base plate steel frame 1 into the steel mold box, and hoist it to the vibrating table of the processing plant.

[0078] 2.6) In addition to the reserved pouring area, pour impermeable concrete or waterproof concrete and expansive concrete in sequence, and then start the vibrating table to make the unit concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com