Hydraulic-electric combined space thruster

A combination of space and thruster technology, applied in thrust reversers, jet propulsion devices, machines/engines, etc., can solve problems such as inability to meet the requirements of low-orbit missions, and achieve the effect of reducing the total mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

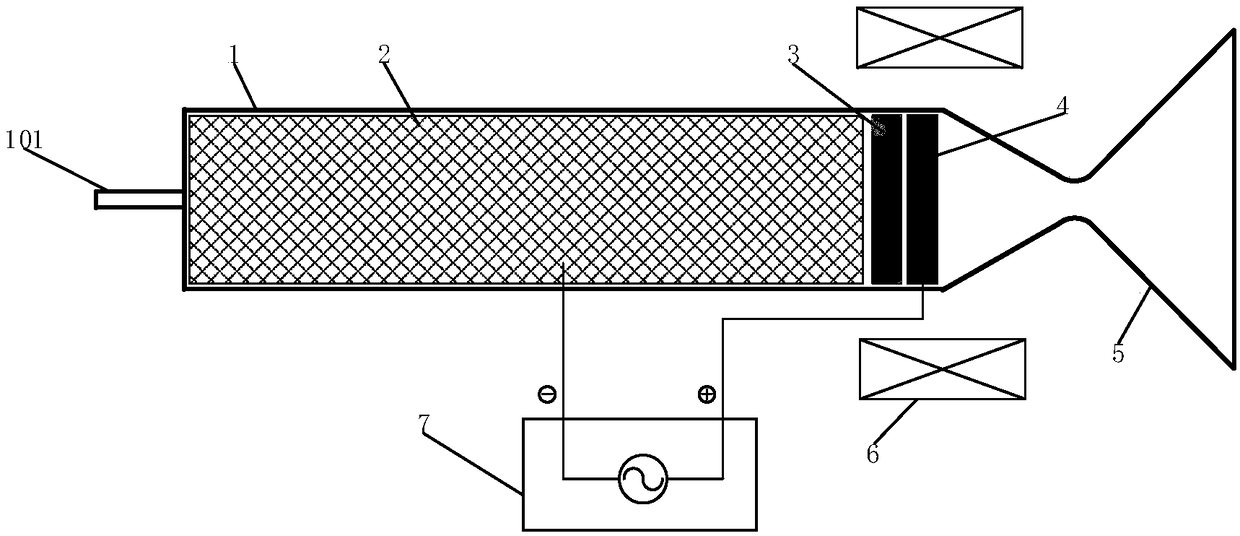

[0024] Such as image 3 As shown, when the aircraft performs a low-orbit mission, the aircraft requires the attitude and orbit control engine to provide a thrust between 1N-20N. At this time, the liquid propellant passes through figure 1 The middle propellant inlet 101 enters the catalyst loading area, and the propellant is decomposed into high-temperature and high-pressure gas under the action of the catalyst. After passing through the porous insulator 3 and the anode 4, the gas expands and accelerates under the action of the nozzle to generate the target thrust. This process converts the internal energy of the propellant into kinetic energy. When the aircraft performs high-orbit or deep-space exploration missions, the aircraft requires attitude and orbit control to provide a specific impulse between 1000s and 3000s. image 3 The medium 7 power supply generates a pulse voltage of 800V, and the surface of the catalyst particles close to the anode in the combustion chamber wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com