Damping rubber and preparation method thereof, engine suspension and automobile

A technology for engine mounts and shock-absorbing rubber, which is applied in the preparation of the shock-absorbing rubber, shock-absorbing rubber, and the automotive field. Rigidity increases and other issues, to improve dispersion, improve damage resistance, reduce stiffness changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

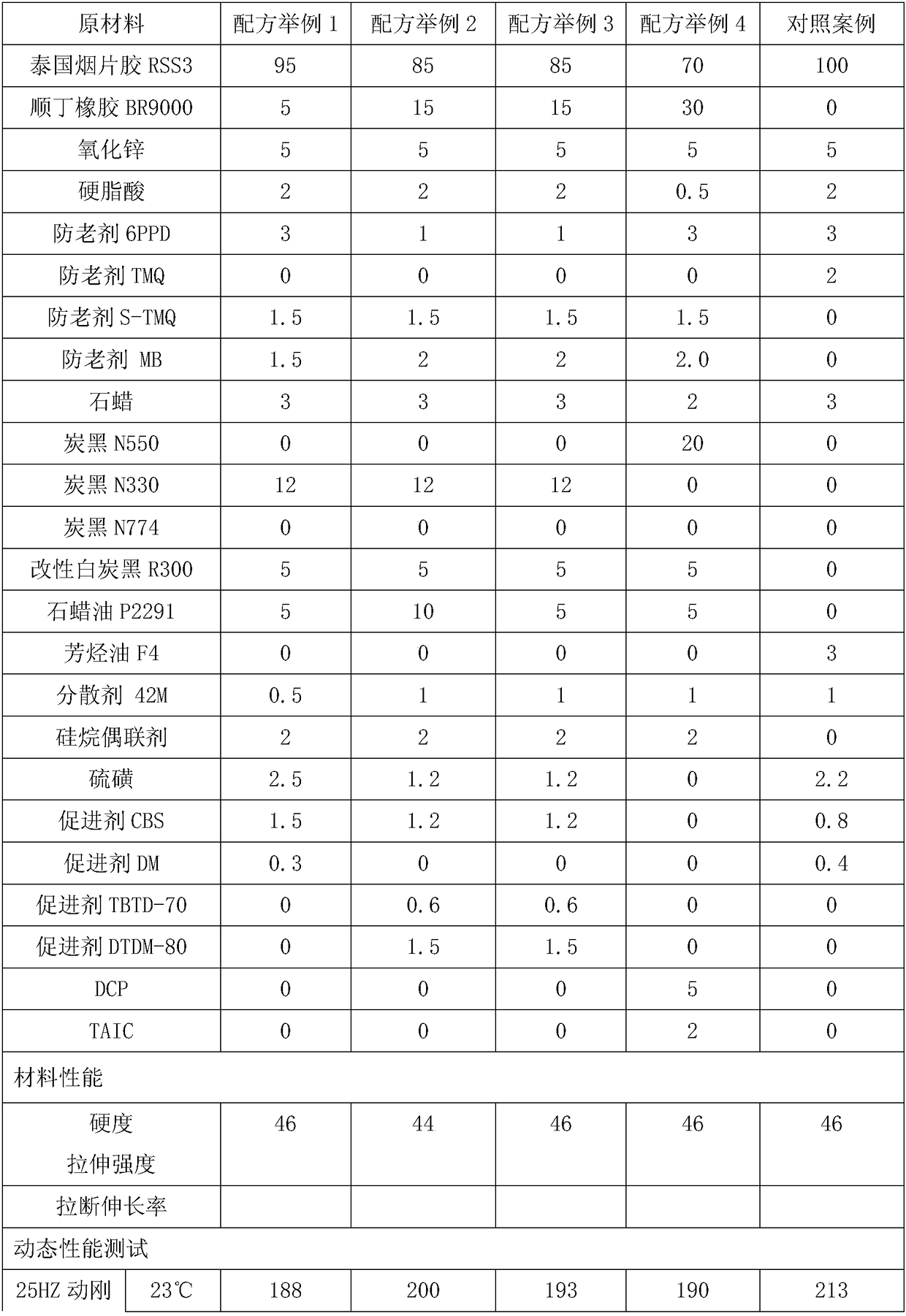

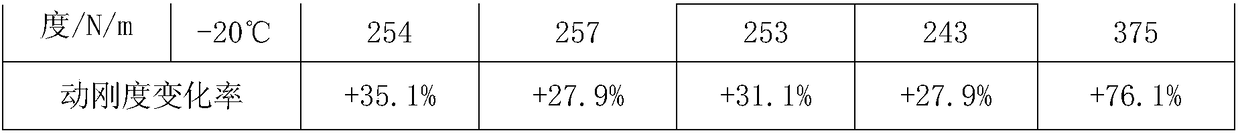

Examples

Embodiment 2

[0038] This embodiment relates to an engine suspension, which is made of the shock-absorbing compound described in the first embodiment. At the same time, this embodiment also relates to an automobile equipped with the above-mentioned engine suspension.

[0039] The engine mount of this embodiment and the automobile adopt the shock-absorbing compound in the first embodiment, which can make the engine mount have better low temperature resistance performance, which is beneficial to improve the quality of the engine mount.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com