High-resolution fluorescent display screen and preparation method and application thereof

A display screen and high-resolution technology, applied in chemical instruments and methods, optics, luminescent materials, etc., can solve the problems of limited service life, low yield, high threshold of OLED technology, etc., achieve simple preparation method, no need for electric drive, use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a high-resolution fluorescent display screen and a manufacturing method thereof.

[0043] A high-resolution fluorescent display:

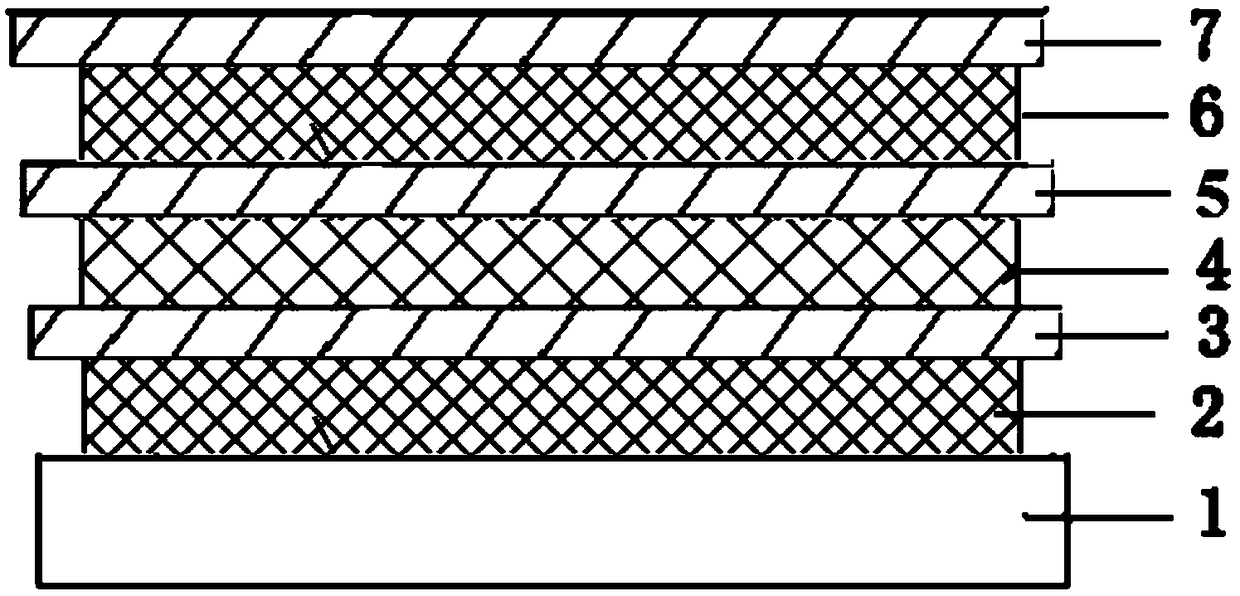

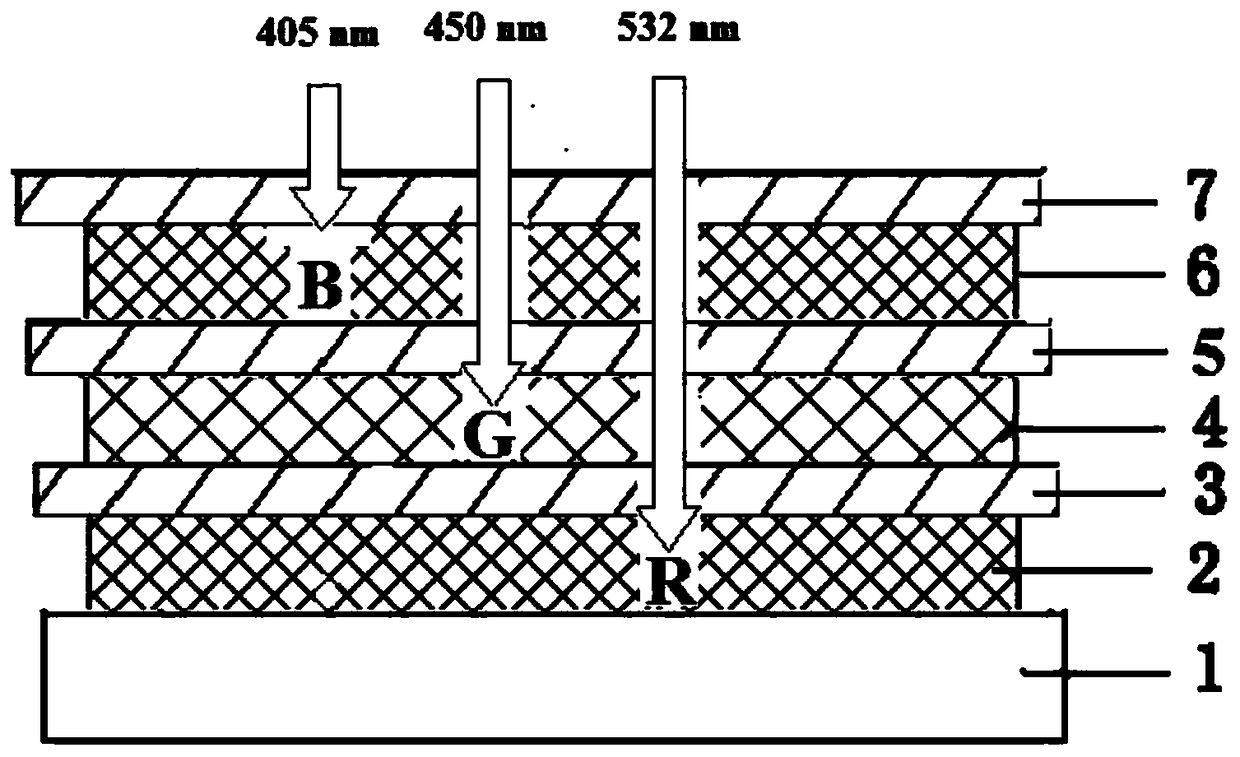

[0044] Such as figure 1 As shown, the high-resolution fluorescent display screen in this embodiment consists of a substrate (1), a red fluorescent material layer (2), a first isolation layer (3), a green fluorescent material layer (4), a second isolation layer (5) , the blue fluorescent material layer (6) and the protective layer (7) are sequentially stacked.

[0045] The substrate is made of glass;

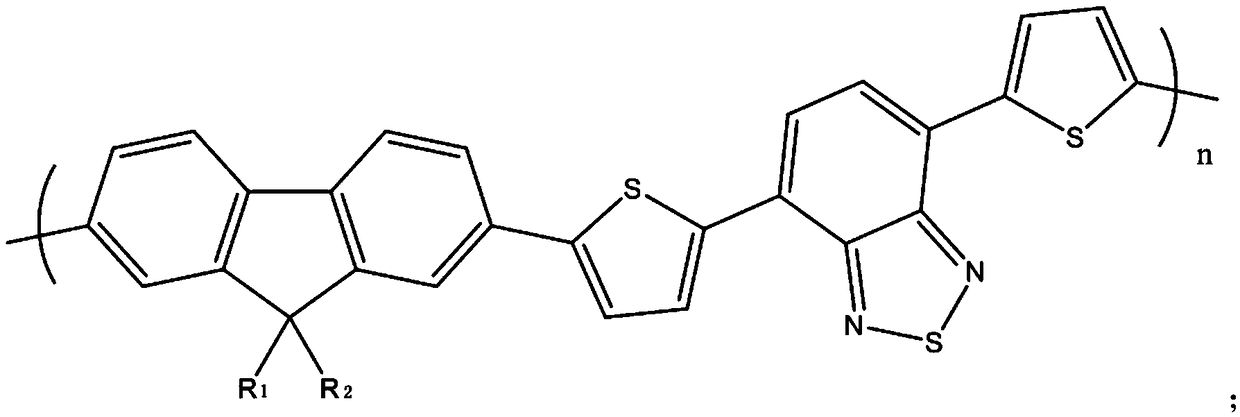

[0046] The structural formula of the material of the red fluorescent material layer is as follows:

[0047]

[0048] The structural formula of the material of the green fluorescent material layer is as follows:

[0049]

[0050] The structural formula of the material of the blue fluorescent material layer is as follows:

[0051]

[0052] Among them, R is C 8 h 17 ;

[0053] The material of the first iso...

Embodiment 2

[0060] This embodiment provides a high-resolution fluorescent display screen and a manufacturing method thereof.

[0061] The structure and preparation method of the high-resolution fluorescent display screen in this embodiment are the same as those in Embodiment 1, the difference lies in the materials of the fluorescent material layer and the isolation layer, and the curing process of each layer.

[0062] Wherein, the material of the fluorescent material layer is a small molecule fluorescent material, specifically as follows:

[0063] The red fluorescent material adopts rhodamine series alcohol-soluble dyes, and the red fluorescent material is dispersed in the heat-crosslinkable acrylic alcohol solution during spin coating. After spin coating, it was cured at 120°C for 10 minutes.

[0064] The green fluorescent material adopts coumarin dye, and the green fluorescent material is dispersed in the heat-crosslinkable polyurethane prepolymer during spin coating. After spin coati...

Embodiment 3

[0068] This embodiment provides a high-resolution fluorescent display screen and a manufacturing method thereof.

[0069] The structure and composition of the high-resolution fluorescent display screen in this embodiment are the same as those in Embodiment 1, the difference is that each layer is prepared by a film-forming method by pulling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com