Multifunctional fabric and preparation method thereof

A multi-functional, fabric technology, applied in chemical instruments and methods, textiles, yarns, etc., can solve the problems of lack of antibacterial, antistatic, wrinkle, easy deformation, etc., to achieve comfortable and wear-resistant wear, eliminate static electricity, hygroscopicity impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038]The present invention also provides a preparation method of the multi-functional fabric, comprising the following steps: yarn preparation → weaving → gray cloth inspection → base fabric dyeing pre-treatment → base fabric dyeing → tenter drying → post-singing → post-finishing → calendering → fabric lamination; yarn preparation includes combed cotton process, the combed cotton process is: blowing carding → combing preparation → combing → first drawing frame → secondary drawing frame → roving → winding → yarn doubling → Twisted yarn; the carding machine adopts the backward feeding method, the diameter of the licker-in roller is 220-280mm, the speed is 800-1400r / min, the speed of the cylinder is 220-350r / min, the number of cover plates is 75-85, and the number of working pieces is 25-35 , speed 120-320mm / min; drawing frame adopts combined number of 5-10, draft multiple 6-12, roving frame adopts spindle gauge 200-220mm, flyer speed 800-1200r / min, spinning frame adopts spindle ...

Embodiment 1

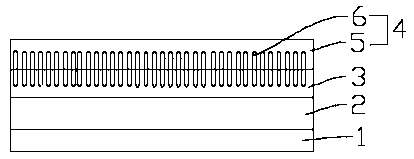

[0052] Base fabric weaving: The mass percentage is: 10% 6K carbon fiber, 20% 35D aramid fiber, 40% 30D wool fiber, 30% 60D acrylic fiber, first twist wool fiber and acrylic fiber into wool acrylic fiber, Use the knitting machine to knit in a triangular arrangement. The knitting sequence is ABC. The number of routes includes 1~6 routes, of which the 1st, 3rd and 5th routes wear wool acrylic fiber, and the 2nd, 4th and 6th routes wear carbon fiber plus aramid fiber. Fiber, gray cloth width 180~185cm, weight 300~305g / m 2 , as above.

[0053] Anti-static layer weaving: the selected mass percentage is: 60% cotton fiber, 10% conductive fiber, 30% glass fiber, weaving by rapier loom or air-jet loom, 2-color or 4-color automatic weft selection, opening time 315° angle , the warp yarn is combined with a twisted doubling machine to combine the conductive fiber and glass fiber at a ratio of 40S∕1, the two-for-one twister twists 1350T / m, S twist, the spindle speed is 8800r / min, and the w...

Embodiment 2

[0057] Base fabric weaving: The mass percentage is: 10% 6K carbon fiber, 30% 35D aramid fiber, 40% 30D wool fiber, 20% 60D acrylic fiber, first twist wool fiber and acrylic fiber into wool acrylic fiber, Use the knitting machine to knit in a triangular arrangement. The knitting sequence is ABC. The number of routes includes 1~6 routes, of which the 1st, 3rd and 5th routes wear wool acrylic fiber, and the 2nd, 4th and 6th routes wear carbon fiber plus aramid fiber. Fiber, gray cloth width 180~185cm, weight 300~305g / m 2 , as above.

[0058] Anti-static layer weaving: the selected mass percentage is: 60% cotton fiber, 20% conductive fiber, 20% glass fiber, weaving by rapier loom or air-jet loom, 2-color or 4-color automatic weft selection, opening time 315° angle , the warp yarn is combined with a twisted doubling machine to combine the conductive fiber and glass fiber at a ratio of 40S∕1, the two-for-one twister twists 1350T / m, S twist, the spindle speed is 8800r / min, and the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com