Recombination structure and structure separating and purifying method

A technology for separation, purification and separation equipment, which is applied in the direction of separating sediment, alumina/aluminum hydroxide by centrifugal force, etc., can solve the problems of low effective utilization rate of circulating mother liquor, less than 2% increase in decomposition rate, and low decomposition rate, etc. Achieve the effect of increasing the efficiency of one cycle, improving production efficiency and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The first step: take the mother liquor of the seed fraction to be separated for analysis and detection, the obtained ak value is 3.5, the content of sodium oxide in the solution is 160 g / kg, and the content of aluminum oxide is 75.2 g / kg. According to the quantitative configuration scheme of the structure ratio, to separate the solution of 1000g of the liquid to be separated, it is necessary to reduce the moisture of 298g;

[0032]Step 2: Concentrate 1000g of the solution to be separated to reduce 298g of water, and then use ultrasound and stirring for 60 minutes to induce the self-assembly process of the structural reorganization at a temperature of 90 degrees to complete the reorganization of its structure;

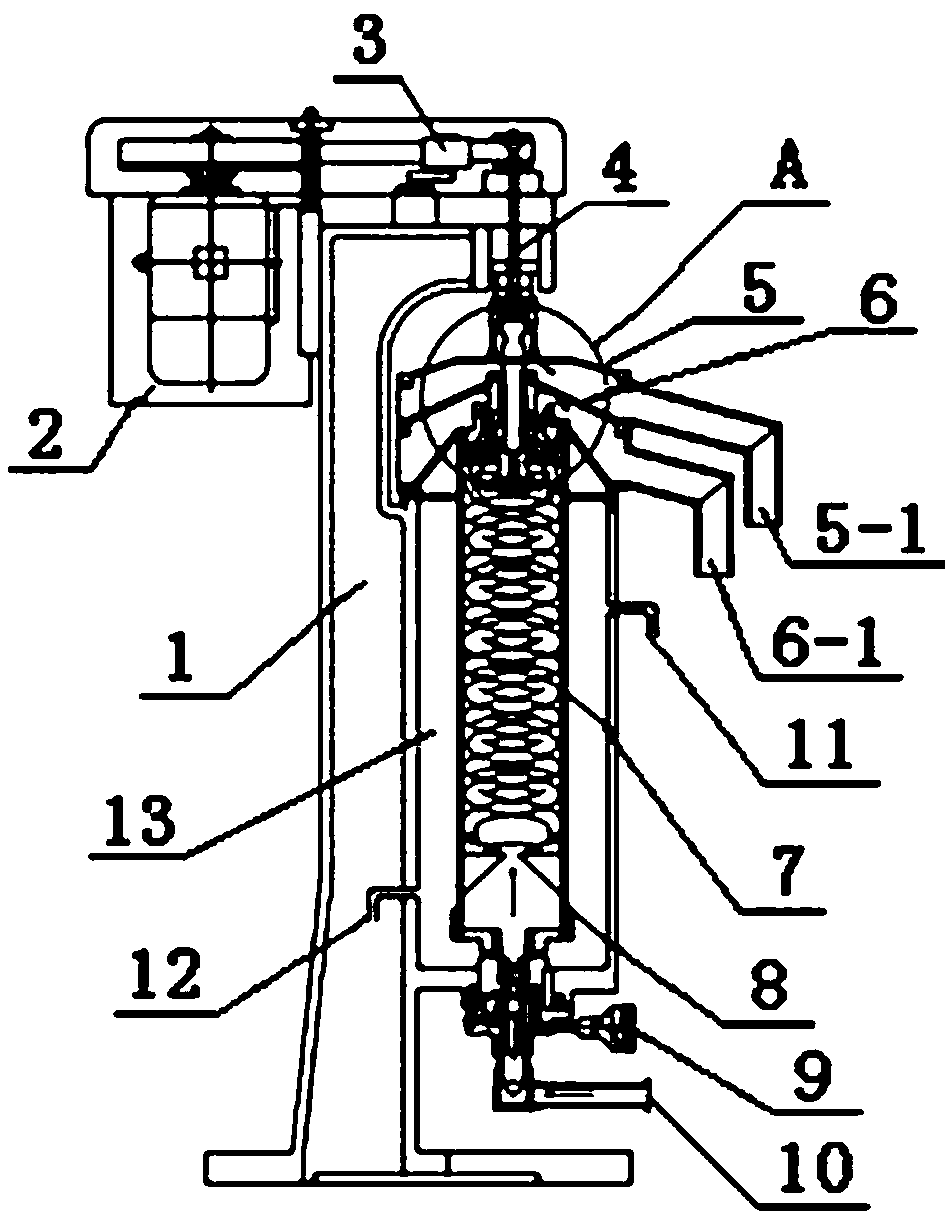

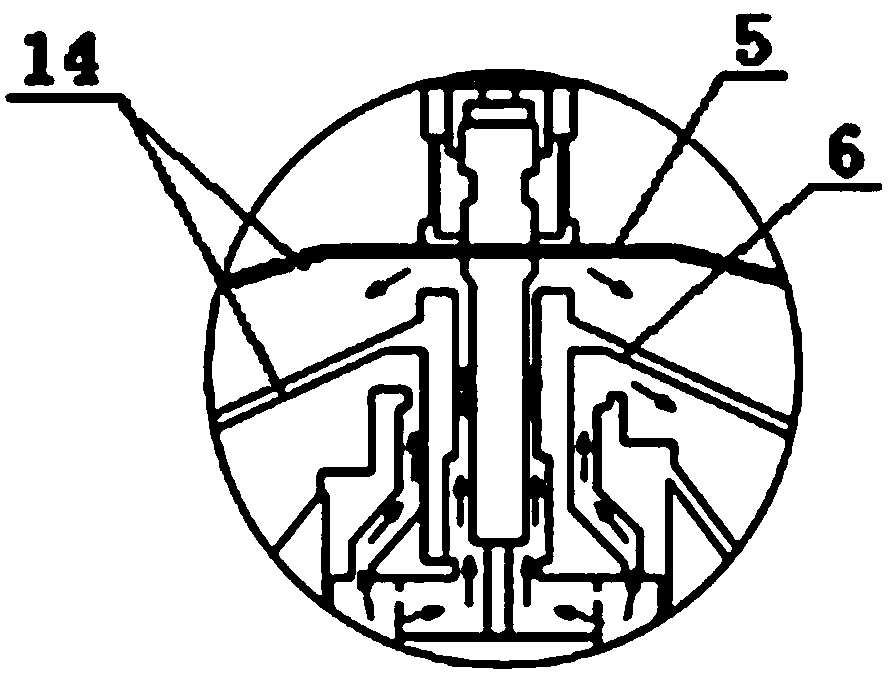

[0033] The third step: the above-mentioned relatively stable solution that has completed the self-assembly process is separated at 90 degrees by a tunnel separation device with a rotating speed of 8000 rpm for 10 minutes, and the separation is repeated 4 times to ...

Embodiment 2

[0035] The first step: take the high-sodium liquid in the process of producing alumina to be separated for analysis and detection, and the obtained ak value is 11, the content of sodium oxide in the solution is 300 g / kg, and the content of alumina is 45 g / kg. By calculating The quantitative configuration scheme of the three structural ratios of sodium, aluminum and water, to separate the solution of 1000g of the liquid to be separated, it is necessary to add 100g of water;

[0036] The second step: add 100g of water to 1000g of the solution to be separated, and then use ultrasound and stirring for 60 minutes to induce the self-assembly process of the structural reorganization at a temperature of 80 degrees to complete the reorganization of its structure;

[0037] The third step: the above solution that has completed the self-assembly process is separated for 20 minutes through a tunnel separation device with a rotating speed of 2000 rpm at 80 degrees. After repeated separation ...

Embodiment 3

[0039] The first step: take the high-sodium liquid in the process of producing alumina to be separated for analysis and detection, and the obtained ak value is 11, the content of sodium oxide in the solution is 300 g / kg, and the content of alumina is 45 g / kg. By calculating The quantitative configuration scheme of the three structural ratios of sodium, aluminum and water, to separate the solution of 1000g of the liquid to be separated, it is necessary to add 100g of water;

[0040] Step 2: Add 100g of water to 1000g of the solution to be separated, and then use ultrasound and stirring for 60 minutes to induce the self-assembly process of the structural reorganization at a temperature of -5 degrees to complete the reorganization of its structure;

[0041] The third step: the above solution that has completed the self-assembly process is separated by a conventional centrifuge separation device at -5 degrees at a speed of 1000 rpm tunnel separation device for 30 minutes. After sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com