Preparation method of light trapping glass for thin film solar cell

A solar cell and thin film technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as affecting the performance of thin films, and achieve the effects of good crystal quality, high activity, and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

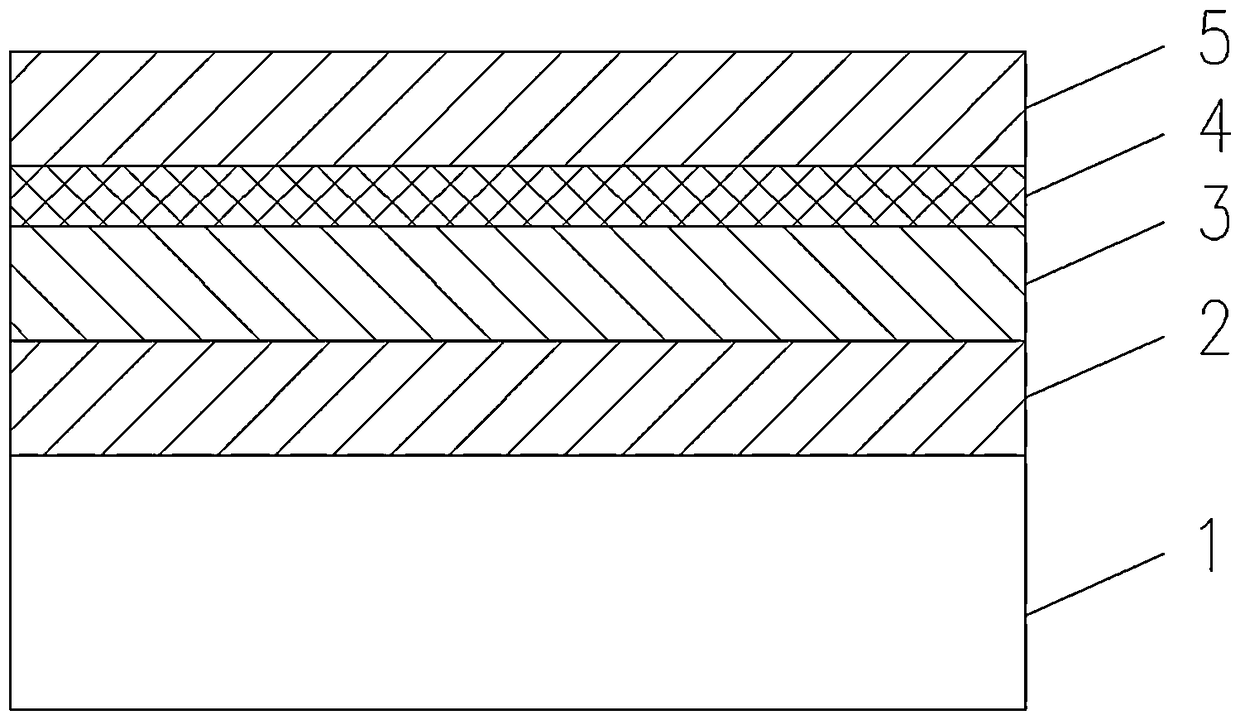

[0028] Such as figure 1 Shown, the present invention provides a kind of preparation method of light-trapping glass for thin-film solar cell, comprises the following steps:

[0029] S1. Immerse the glass substrate 1 in the piranha solution. The piranha solution is a mixed solution of 70% concentrated sulfuric acid and 30% hydrogen peroxide, clean the glass substrate, remove impurities on the surface of the glass substrate, and simultaneously hydroxylate the surface of the glass substrate to improve its affinity. Water-based, so that the sputtering of subsequent thin films has better bonding and adhesion;

[0030] S2, placing the glass substrate 1 in a magnetron sputtering chamber, bombarding the surface of the glass substrate 1 with an Ar ion beam to further clean the glass substrate, enhancing the hydrophilicity of the surface of the glass substrate and stimulating the surface activity of the glass substrate;

[0031] S3. Use the AZO target with an Al doping concentration of ...

Embodiment 2

[0037] Such as figure 1 Shown, the present invention provides a kind of preparation method of light-trapping glass for thin-film solar cell, comprises the following steps:

[0038] S1. Immerse the glass substrate 1 in the piranha solution. The piranha solution is a mixed solution of 70% concentrated sulfuric acid and 30% hydrogen peroxide, clean the glass substrate, remove impurities on the surface of the glass substrate, and simultaneously hydroxylate the surface of the glass substrate to improve its affinity. Water-based, so that the sputtering of subsequent thin films has better bonding and adhesion;

[0039] S2, placing the glass substrate 1 in a magnetron sputtering chamber, bombarding the surface of the glass substrate 1 with an Ar ion beam to further clean the glass substrate, enhancing the hydrophilicity of the surface of the glass substrate and stimulating the surface activity of the glass substrate;

[0040] S3. Use the AZO target with Al doping concentration of 1.0...

Embodiment 3

[0046] Such as figure 1 Shown, the present invention provides a kind of preparation method of light-trapping glass for thin-film solar cell, comprises the following steps:

[0047] S1. Immerse the glass substrate 1 in the piranha solution. The piranha solution is a mixed solution of 70% concentrated sulfuric acid and 30% hydrogen peroxide, clean the glass substrate, remove impurities on the surface of the glass substrate, and simultaneously hydroxylate the surface of the glass substrate to improve its affinity. Water-based, so that the sputtering of subsequent thin films has better bonding and adhesion;

[0048] S2, placing the glass substrate 1 in a magnetron sputtering chamber, bombarding the surface of the glass substrate 1 with an Ar ion beam to further clean the glass substrate, enhancing the hydrophilicity of the surface of the glass substrate and stimulating the surface activity of the glass substrate;

[0049] S3. Use the AZO target with an Al doping concentration of 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com