Slurry for lava slab, lava slab and processing method thereof

A processing method and technology of lava, applied in the field of slurry for lava slabs, can solve the problems of not having sound absorption and noise reduction functions, and being unable to enter the ranks of mid-to-high-end decorative products, etc., to achieve strong cation exchange adsorption capacity, enhance competitiveness, and high fire resistance The effect of grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

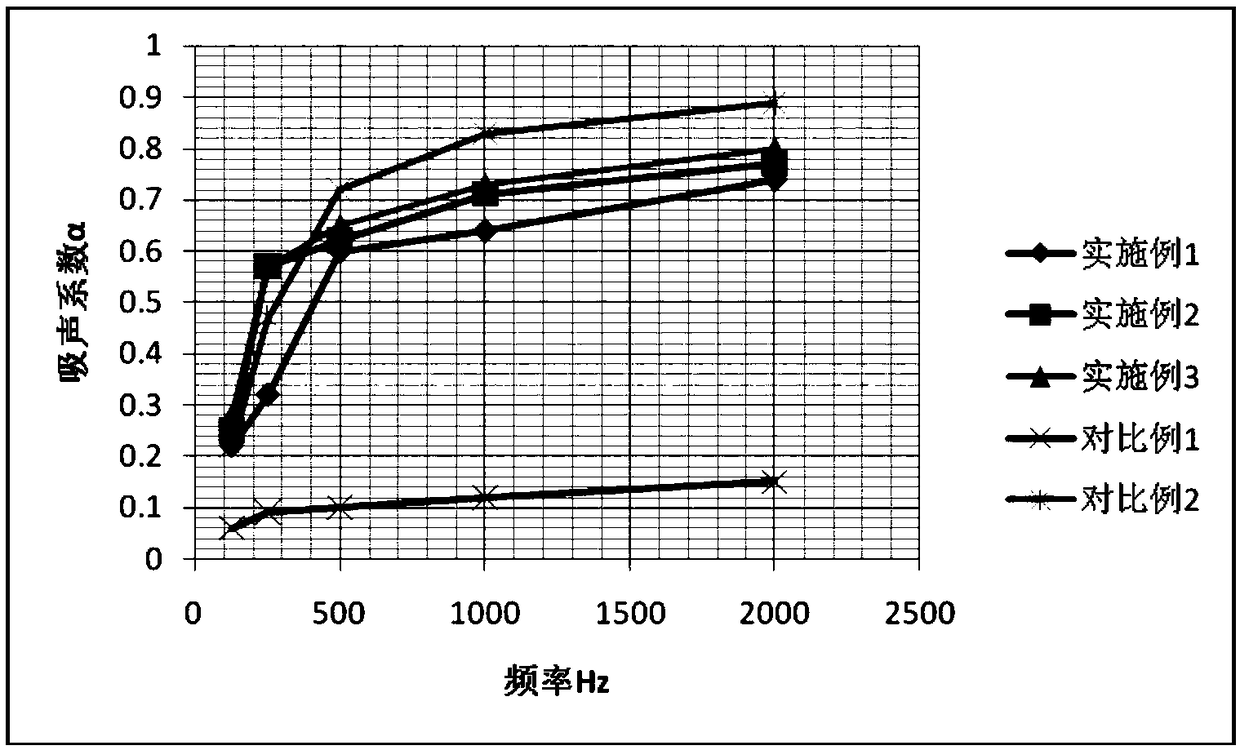

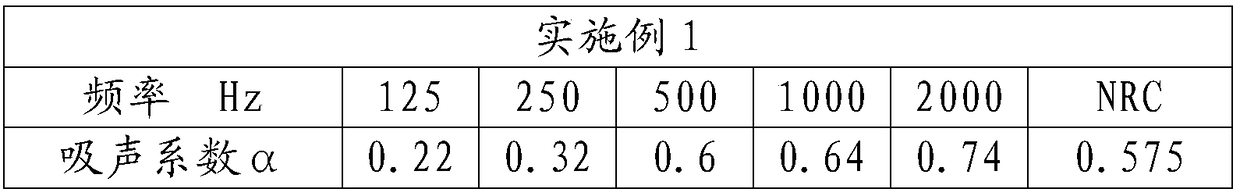

Embodiment 1

[0048] The invention provides a slurry for lava slabs. The slurry comprises 35g of cement, 35g of magnesium oxide powder, 2g of perlite particles, 5g of vermiculite powder, 1g of polyurethane, 2g of propylene milk and 30g of water in parts by weight.

[0049] The invention provides a lava plate, which comprises two layers of slurry and one layer of glass fiber cloth.

[0050] A kind of processing method of lava plate provided by the invention:

[0051] 1) Weigh according to the above raw materials: 35g of cement, 35g of magnesium oxide powder, 2g of perlite particles, 5g of vermiculite powder, 1g of polyurethane, 2g of acrylic milk and 30g of water; prepare glass fiber cloth;

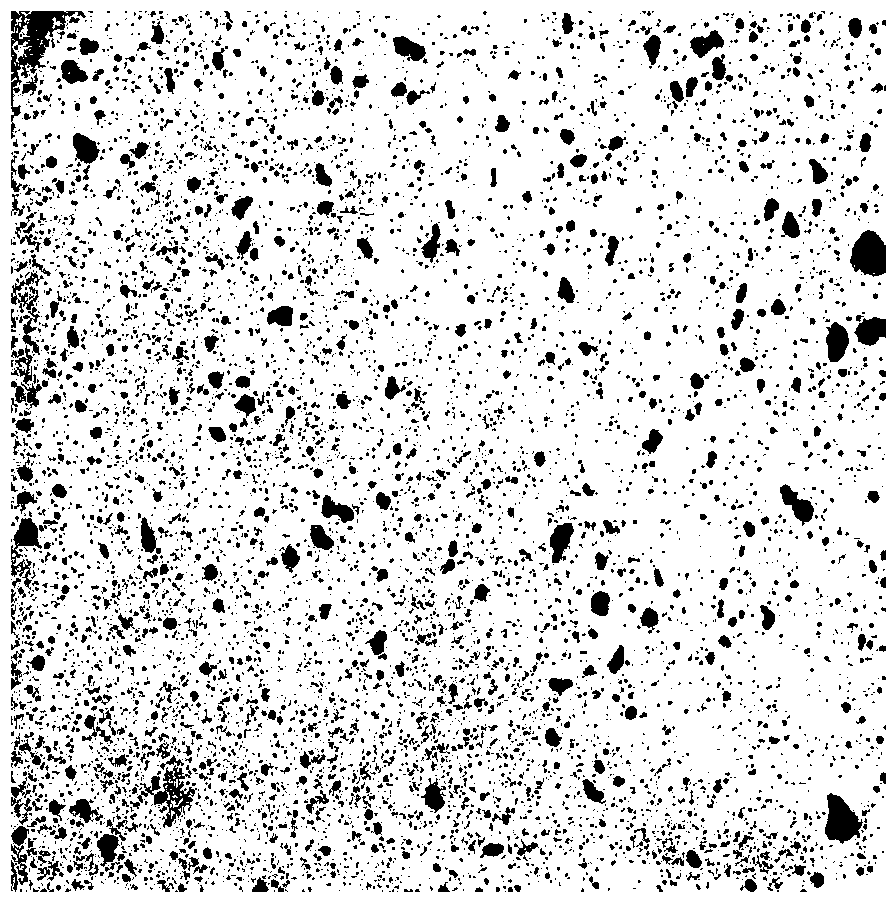

[0052] 2) Stir the slurry with air; stir for 50 minutes, so that the slurry raw materials are evenly mixed and filled with a large number of air bubbles;

[0053] 3) Molding: Lay the slurry stirred in step 2) on a layer in the mold, then lay a layer of glass fiber cloth on it, and then lay a layer of s...

Embodiment 2

[0058] The slurry for lava slabs provided by the invention comprises, in parts by weight, 40 g of cement, 40 g of magnesium oxide powder, 2.5 g of perlite particles, 8 g of vermiculite powder, 2 g of polyester, 3 g of acrylic milk and 35 g of brine.

[0059] The invention provides a lava plate, which comprises three layers of slurry and two layers of glass fiber cloth.

[0060] A kind of processing method of lava plate provided by the invention:

[0061] 1) Weigh according to the above raw materials: 40g of cement, 40g of magnesium oxide powder, 2.5g of perlite particles, 8g of vermiculite powder, 2g of polyester, 3g of propylene milk and 35g of brine; prepare glass fiber cloth;

[0062] 2) Stir the slurry with air; stir for 45 minutes, so that the slurry raw materials are evenly mixed and filled with a large number of air bubbles;

[0063] 3) Molding: Lay the slurry stirred in step 2) on a layer in the mold, then lay a layer of glass fiber cloth on it, then lay a layer of sl...

Embodiment 3

[0068] The slurry for lava slabs provided by the invention comprises 45g of cement, 45g of magnesium oxide powder, 5g of vermiculite powder, 2g of perlite particles, 1g of polyurethane, 2g of propylene milk and 30g of brine in parts by weight.

[0069] The invention provides a lava plate, which comprises three layers of slurry and two layers of glass fiber cloth.

[0070] A kind of processing method of lava plate provided by the invention:

[0071] 1) Weigh according to the above raw materials: 45g of cement, 45g of magnesium oxide powder, 5g of vermiculite powder, 2g of perlite particles, 1g of polyurethane, 2g of propylene milk and 30g of brine; prepare glass fiber cloth;

[0072] 2) Stir the slurry with air; stir for 50 minutes, so that the slurry raw materials are evenly mixed and filled with a large number of air bubbles;

[0073] 3) Molding: Lay the slurry stirred in step 2) on a layer in the mold, then lay a layer of glass fiber cloth on it, then lay a layer of slurry,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com