Aging-resistant anti-bacterial wood plastic composite board and preparation method thereof

A composite board, anti-aging technology, applied in the field of composite materials, can solve the problems of large surface polarity differences, plastic substrates are easily affected by the environment, and cannot meet people's requirements, and achieve excellent mechanical properties and aging resistance, and resist foreign microorganisms The effect of corrosion, excellent antibacterial, sterilization and antifungal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

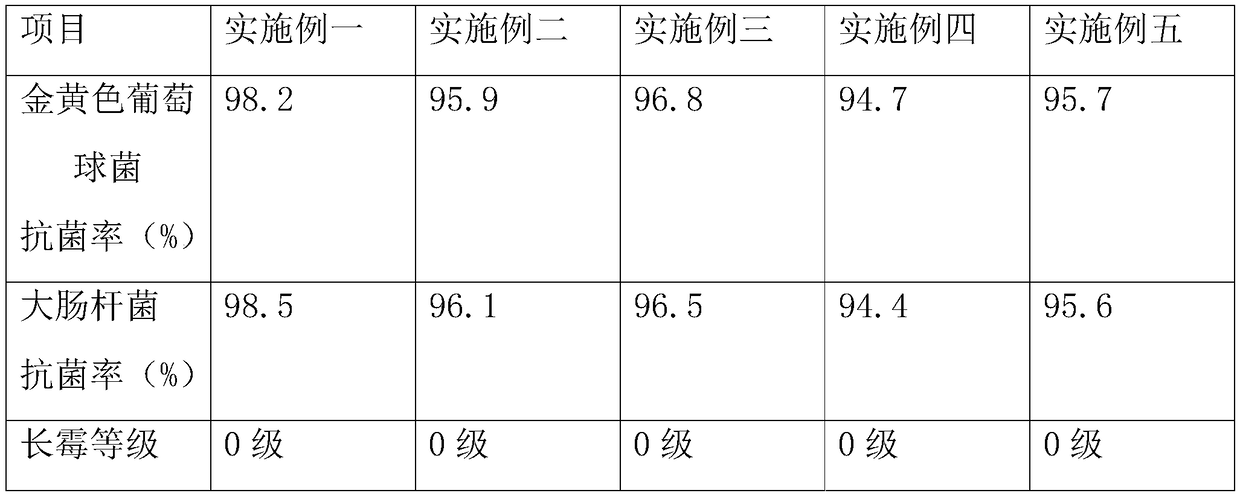

Examples

Embodiment 1

[0038] This embodiment provides an anti-aging and antibacterial wood-plastic composite board, which includes the following raw material components in parts by weight: 90 parts of polyvinyl chloride, 65 parts of wood flour, 18 parts of ramie fiber, 17 parts of calcite powder, and 10 parts of talc powder , 8 parts of diatomaceous earth, 8 parts of shell powder, 2 parts of hokuto stone powder, 0.5 parts of titanium dioxide, 3 parts of pine needle powder, 2 parts of naringenin, 1.5 parts of lemongrass, 2.5 parts of apple eucalyptus, 1 part of lemon eucalyptus , 3 parts of naked flower purple pearl, 2 parts of holly leaves, 0.5 parts of coupling agent, 6 parts of stabilizer, 3 parts of oxidized polyethylene wax, 3 parts of antioxidant, 1 part of ultraviolet absorber.

[0039] In this example, the stabilizer is made by mixing zinc stearate and calcium stearate at a mass ratio of 1:3; the coupling agent is titanate coupling agent PN-130 and aluminate coupling agent A mixture of joint...

Embodiment 2

[0047] This embodiment provides an anti-aging and antibacterial wood-plastic composite board, which includes the following raw material components in parts by weight: 85 parts of polyvinyl chloride, 63 parts of wood flour, 16 parts of ramie fiber, 16 parts of calcite powder, and 9 parts of talc powder , 6 parts of diatomaceous earth, 7 parts of shell powder, 1.5 parts of hokutou stone powder, 0.3 parts of titanium dioxide, 2.5 parts of pine needle powder, 1.7 parts of naringenin, 1.3 parts of lemongrass, 2.2 parts of apple eucalyptus leaves, 0.7 parts of lemon eucalyptus leaves , 2.5 parts of naked flower purple pearl, 1.8 parts of holly leaves, 0.4 parts of coupling agent, 5 parts of stabilizer, 2.5 parts of oxidized polyethylene wax, 2 parts of antioxidant, 0.7 part of ultraviolet absorber.

[0048] In this embodiment, the stabilizer is made by mixing zinc stearate and calcium stearate at a mass ratio of 1:3; the coupling agent is aluminate coupling agent JTW-181; the antioxi...

Embodiment 3

[0056]This embodiment provides an anti-aging antibacterial wood-plastic composite board, which includes the following raw material components in parts by weight: 90 parts of polyvinyl chloride, 60 parts of wood flour, 18 parts of ramie fiber, 15 parts of calcite powder, and 10 parts of talcum powder , 5 parts of diatomaceous earth, 8 parts of shell powder, 1 part of Hokuto stone powder, 0.5 part of titanium dioxide, 2 parts of pine needle powder, 2 parts of naringenin, 1 part of lemongrass, 2.5 parts of apple eucalyptus, 0.5 part of lemon eucalyptus , 3 parts of naked flower purple pearls, 1.5 parts of holly leaves, 0.5 parts of coupling agent, 4 parts of stabilizer, 3 parts of oxidized polyethylene wax, 1.5 parts of antioxidant, and 1 part of ultraviolet absorber.

[0057] In this embodiment, the stabilizer is made by mixing zinc stearate and calcium stearate at a mass ratio of 1:3; the coupling agent is aluminate coupling agent JTW-181; the antioxidant The antioxidant is mad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com