A kind of self-adhesive sound insulation expansion glue and preparation method thereof

A self-adhesive, formulated technology, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

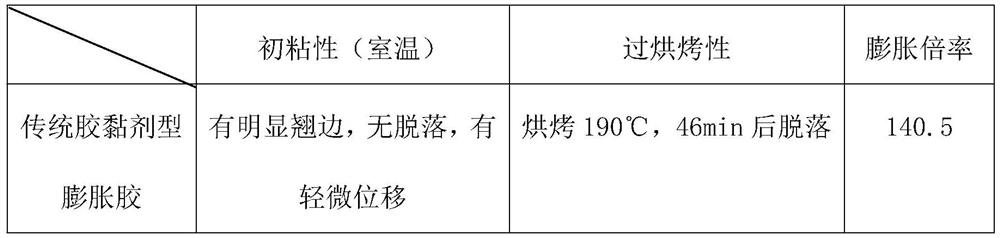

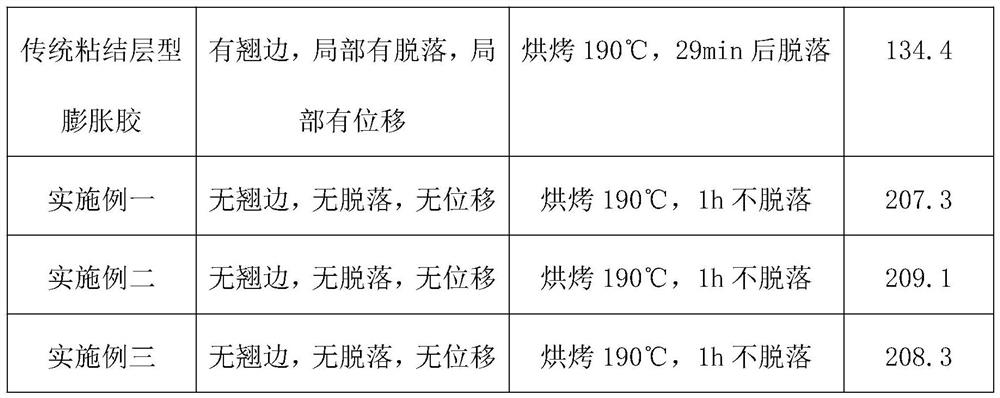

Examples

Embodiment 1

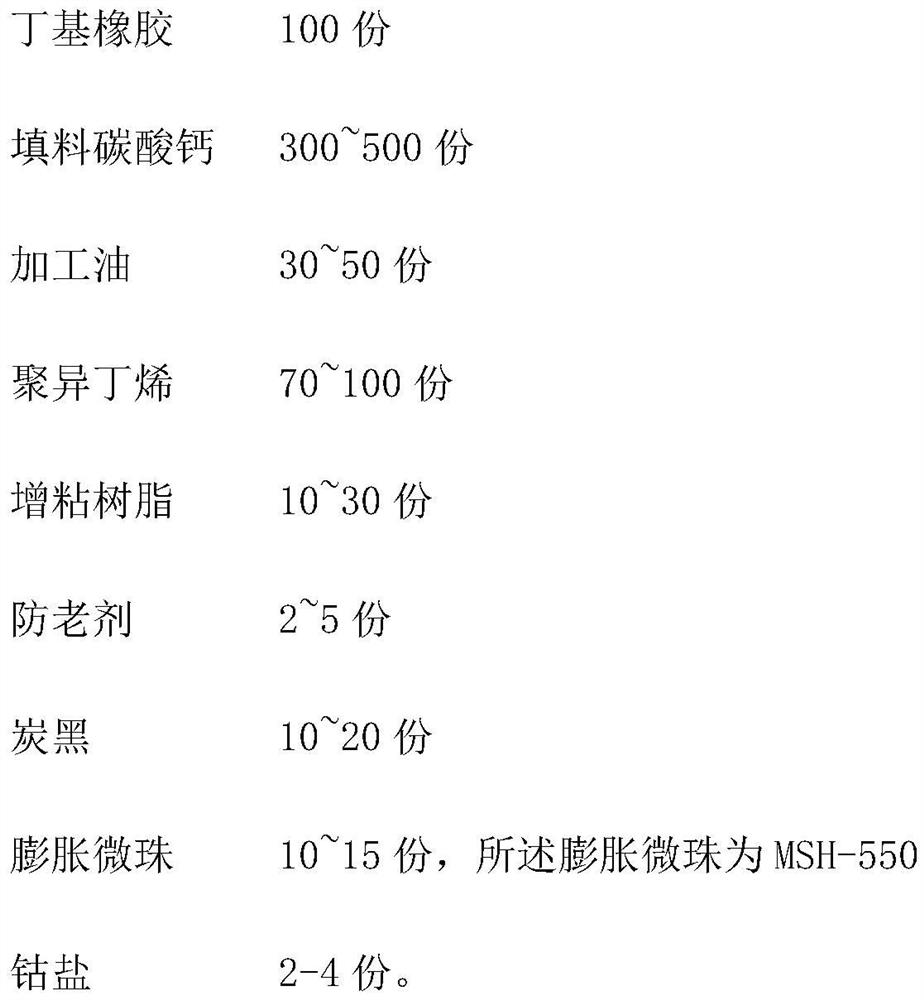

[0032] Embodiment 1. The formula of the self-adhesive sound-insulating expansion glue of the present embodiment is:

[0033] Component Mixing ratio (parts by weight)

[0034] Butyl rubber 100 parts

[0035] Filler calcium carbonate 300 parts

[0036] 30 parts processing oil

[0037] Polyisobutylene 70 parts

[0038] Tackifying resin 10 parts

[0039] Anti-aging agent 2 parts

[0040] Carbon black 20 parts

[0041] 10 servings of expanded microbeads

[0042] Cobalt salt 2 parts.

[0043] Among them, the processing oil is naphthenic oil, the tackifying resin is C5 petroleum resin, the anti-aging agent is N-phenyl-β-naphthylamine, and the expansion microbeads are MSH-550.

Embodiment 2

[0044] Embodiment two, the formula of the self-adhesive sound-insulating expansion glue of the present embodiment is:

[0045] Component Mixing ratio (parts by weight)

[0046] Butyl rubber 100 parts

[0047] Filler calcium carbonate 500 parts

[0048] Processing oil 50 parts

[0049] Polyisobutylene 100 parts

[0050] Tackifying resin 30 parts

[0051] Anti-aging agent 5 parts

[0052] Carbon black 15 parts

[0053] Expanded microbeads 15 parts

[0054] 4 parts cobalt salt.

[0055] Among them, the processing oil is naphthenic oil, the tackifying resin is terpene resin, the anti-aging agent is N-phenyl-β-naphthylamine, and the expanded microbeads are MSH-550.

Embodiment 3

[0056] Embodiment three, the formula of the self-adhesive sound-insulating expansion glue of the present embodiment is:

[0057] Component Mixing ratio (parts by weight)

[0058] Butyl rubber 100 parts

[0059] Filler calcium carbonate 400 parts

[0060] Processing oil 450 parts

[0061] Polyisobutylene 90 parts

[0062] Tackifying resin 25 parts

[0063] Anti-aging agent 4 parts

[0064] Carbon black 10 parts

[0065] 13 servings of expanded microbeads

[0066] 4 parts of cobalt salt.

[0067] Among them, the processing oil is paraffin base oil, the tackifying resin is 203 resin or cobalt caprate resin, the anti-aging agent is N-phenyl-β-naphthylamine, and the expanded microbeads are MSH-550.

[0068] The preparation method of self-adhesive sound-insulating expansion glue of the present invention is as follows:

[0069] 1. Knead butyl rubber and 100-200 parts of filler calcium carbonate, disperse in the kneader for about 10 minutes, add polyisobutylene, anti-aging ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com