Softening agent film preparation technology

A preparation process and softener technology, applied in the field of preparation technology of softener films, can solve the problems of no antibacterial and bactericidal ability, poor anti-oxidative yellowing ability, no anti-yellowing effect, etc., and achieve excellent antibacterial and bactericidal ability, Good anti-oxidative yellowing ability, excellent use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

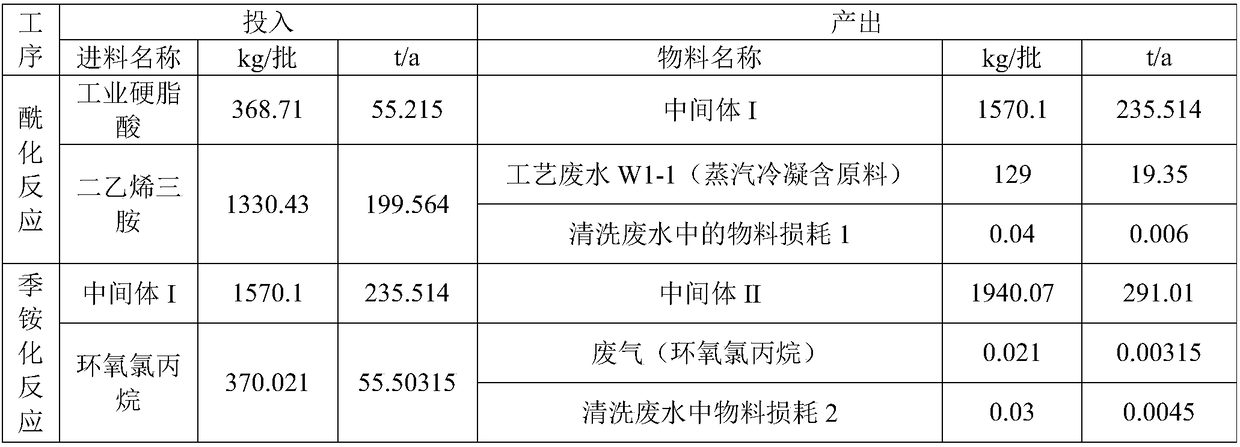

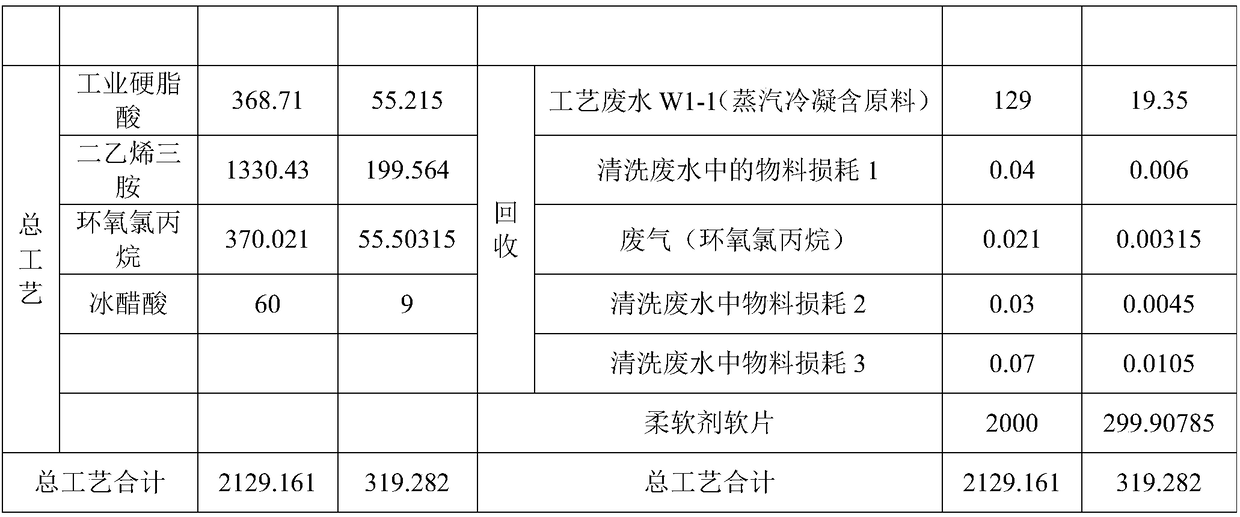

[0043] A kind of preparation technology of softener film, described preparation technology comprises following preparation steps:

[0044] 1) Acylation reaction: put the hydrogenated oil in a container, then add industrial stearic acid into the container for preheating with hot steam at 85°C, preheat until the industrial stearic acid dissolves and then pump diethylenetriamine to Heat the steam to 125°C and keep it warm for 150 minutes. During the heat preservation reaction, the steam is collected by a condensing device at the same time, and intermediate I is obtained after the reaction;

[0045] 2) Quaternization reaction: Cool the intermediate I after step 1) to 75°C, and add epichlorohydrin dropwise to intermediate I within 1.5 hours in a uniform dropwise manner, and the dropwise addition is completed Then heat up to 125°C with hot steam, then carry out a second heat preservation reaction for 200 minutes, and then cool down to 75°C after the completion of the reaction to obt...

Embodiment 2

[0049] A kind of preparation technology of softener film, described preparation technology comprises following preparation steps:

[0050] 1) Acylation reaction: put the hydrogenated oil in a container, then add industrial stearic acid into the container for preheating with hot steam at 95°C, preheat until the industrial stearic acid dissolves and then pump diethylenetriamine to Heat the steam to 140°C and keep it warm for 105 minutes. During the keep warm reaction, the steam is collected by a condensing device at the same time, and intermediate I is obtained after the reaction;

[0051] 2) Quaternization reaction: Cool the intermediate I after the reaction in step 1) to 85°C, and add epichlorohydrin dropwise to intermediate I within 2 hours by dropping at a constant speed. Heat up to 140°C with hot steam, then carry out a second heat preservation reaction for 150 minutes, after the reaction is completed, cool down to 85°C to obtain intermediate II;

[0052] 3) Slicing: Slowl...

Embodiment 3

[0055] A kind of preparation technology of softener film, described preparation technology comprises following preparation steps:

[0056] 1) Acylation reaction: put the hydrogenated oil in a container, then add industrial stearic acid into the container for preheating with hot steam at 90°C, preheat until the industrial stearic acid dissolves and then pump diethylenetriamine to Heat the steam to 130°C and keep it warm for 120 minutes. During the heat preservation reaction, the steam is collected by a condensing device at the same time. After the reaction, intermediate I is obtained;

[0057] 2) Quaternization reaction: Cool the intermediate I after step 1) to 80°C, and add epichlorohydrin dropwise to intermediate I within 2 hours in a uniform dropwise manner. Heat up to 130°C with hot steam, then carry out a second heat preservation reaction for 180 minutes, after the reaction is completed, cool down to 80°C to obtain intermediate II;

[0058] 3) Slicing: Slowly add glacial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com