A laser white light composite interferometric measurement system and method

A technology of interferometric measurement and white light, which is applied in measurement devices, optical devices, instruments, etc., to achieve the effect of expanding the measurement range of the system, expanding the measurement range and improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention more clear, the structure, principle, experimental process and results of the present invention will be further described below in conjunction with the accompanying drawings.

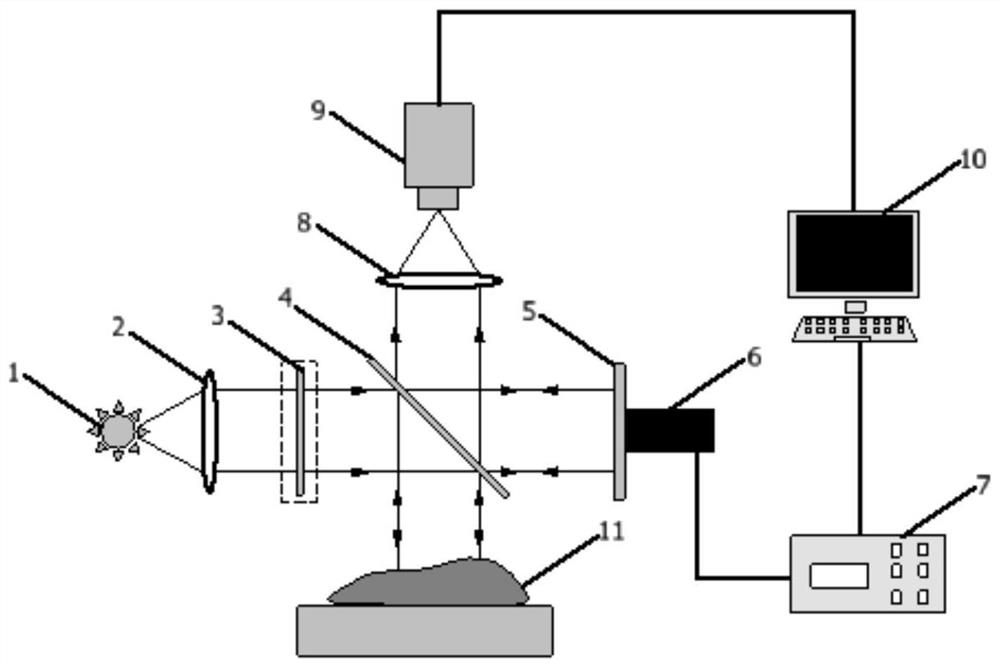

[0031] like figure 1 As shown, a kind of laser white light compound interferometry system provided by the present invention comprises a white light LED light source 1, a collimating lens 2, an optical filter 3, a beam splitter 4, a reference mirror 5, a piezoelectric ceramic displacement stage 6 and a controller A closed-loop micro-displacement system composed of 7, a microscope objective lens 8, a CCD photodetector 9 and a computer 10. The optical filter 3 can filter out single-frequency laser light from white light for monochromatic light phase shift interferometry; the optical filter can be removed when performing white light scanning interferometry.

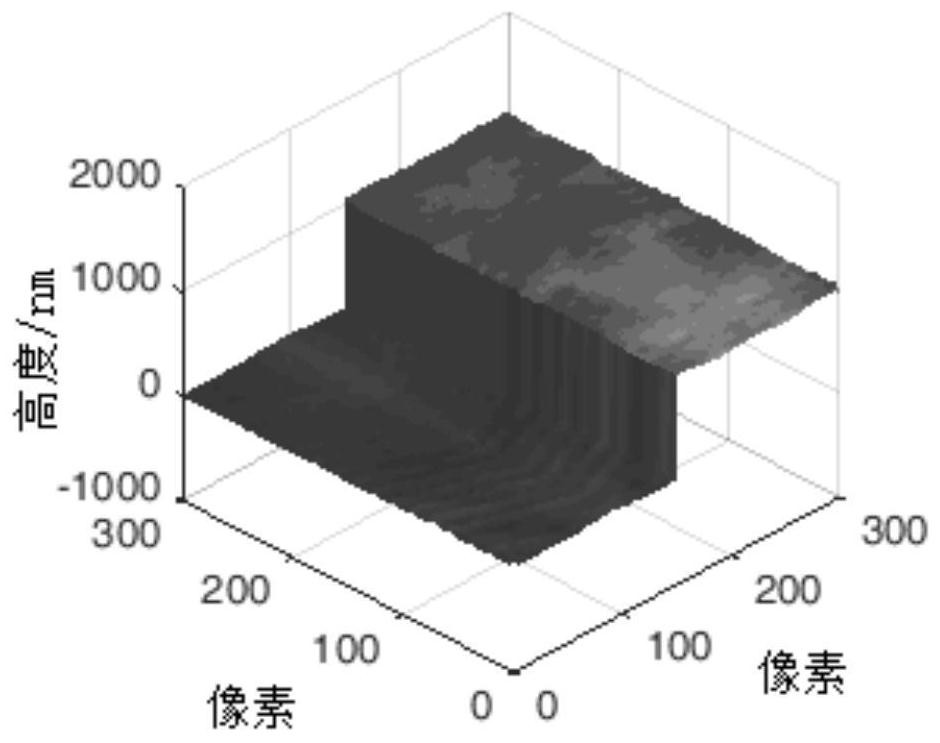

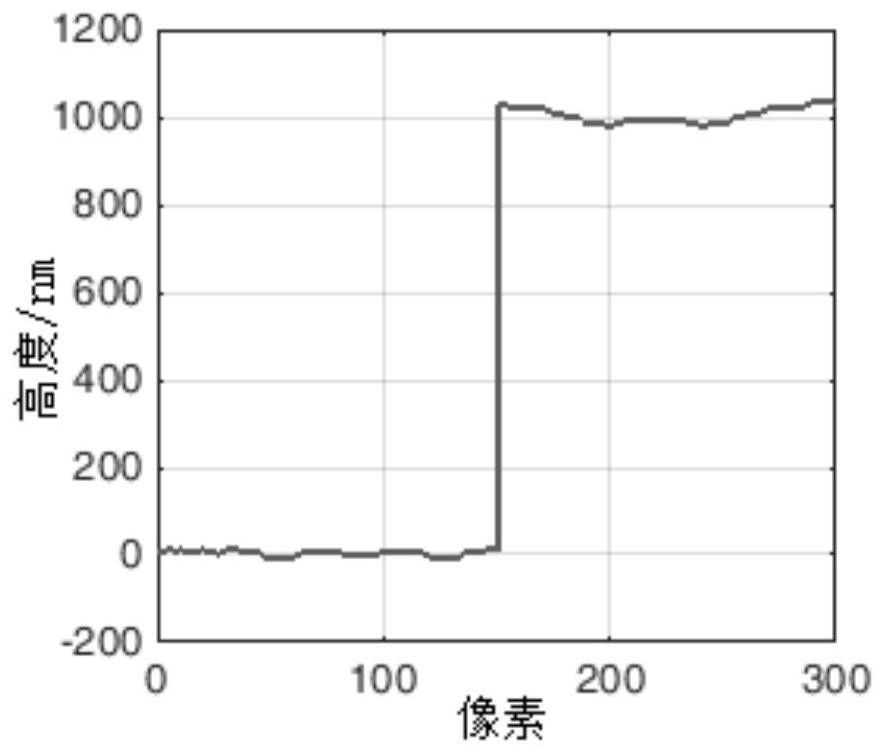

[0032]In order to realize the measurement of the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com