Method for calculating micro dendritic growth in continuous casting solidification on basis of cellular automaton

A cellular automaton and continuous casting billet technology, applied in the directions of calculation, computer-aided design, design optimization/simulation, etc., can solve the problem of non-convergence of calculation results, deviation of growth angle, unit cell solid phase ratio and liquid solute concentration. Problems such as non-physical results occur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

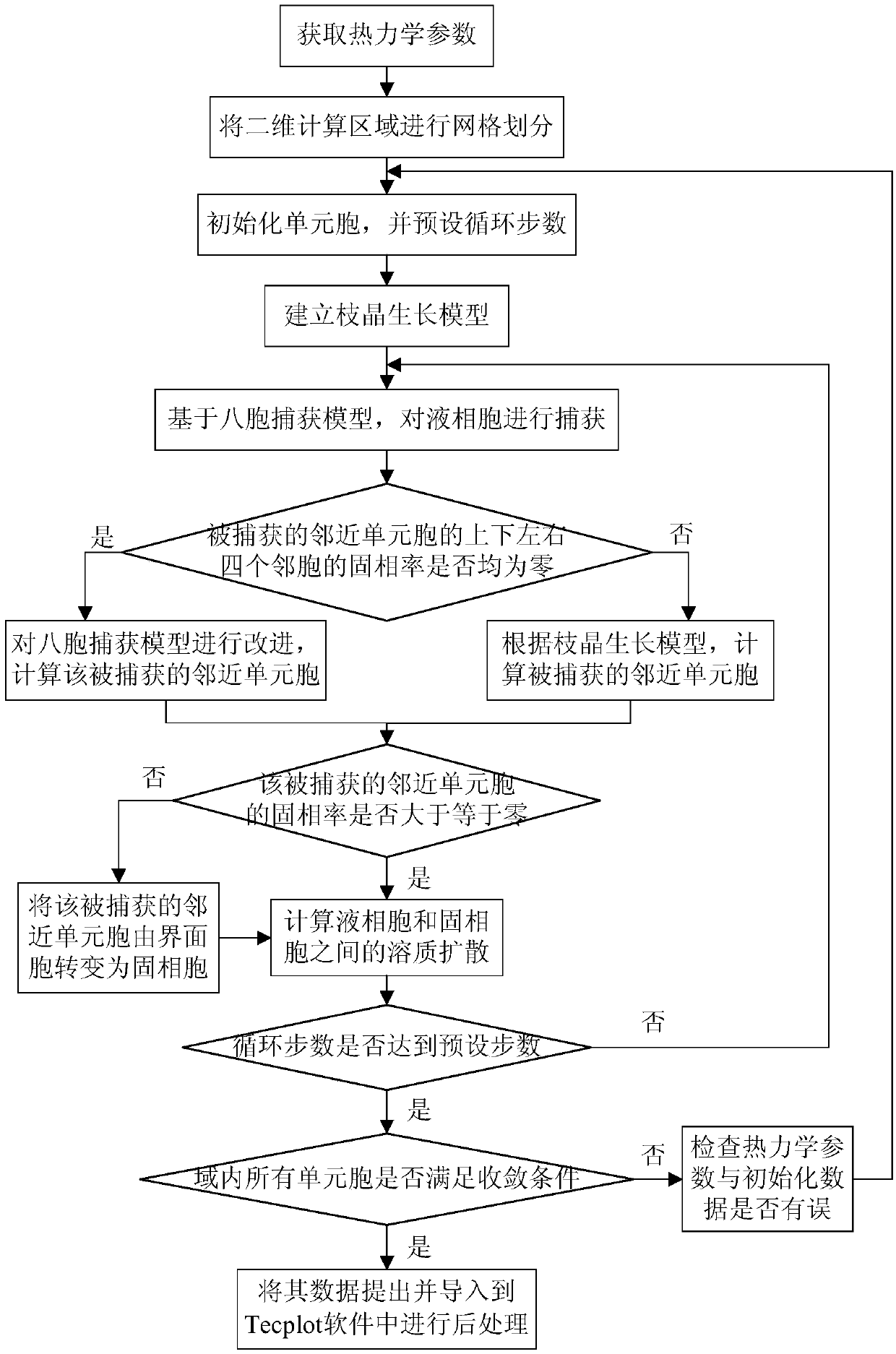

[0061] The flow of the method for calculating the growth of microscopic dendrites in the solidification of continuous casting slabs based on cellular automata is as follows: figure 1 As shown, the method of this embodiment is as follows.

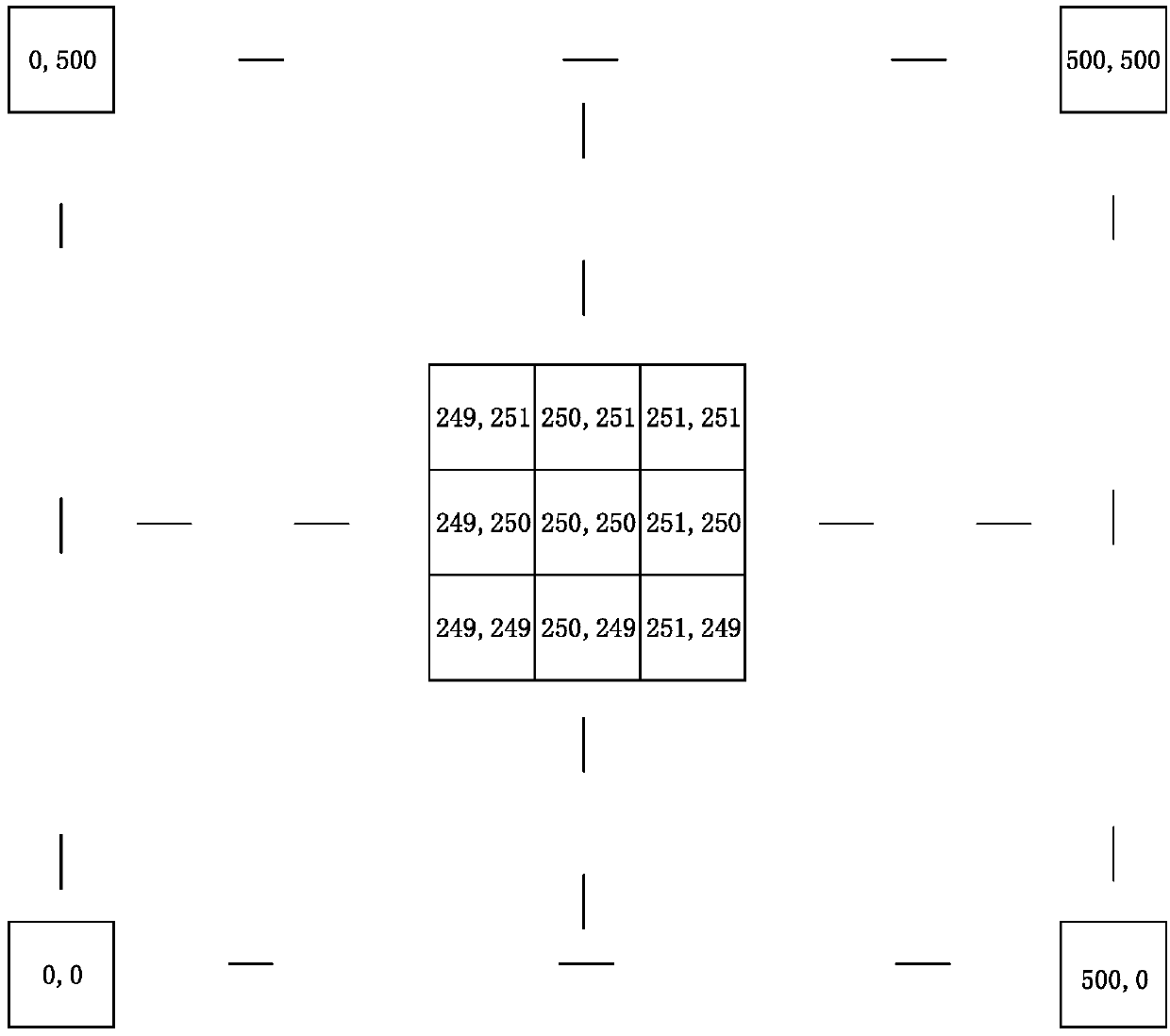

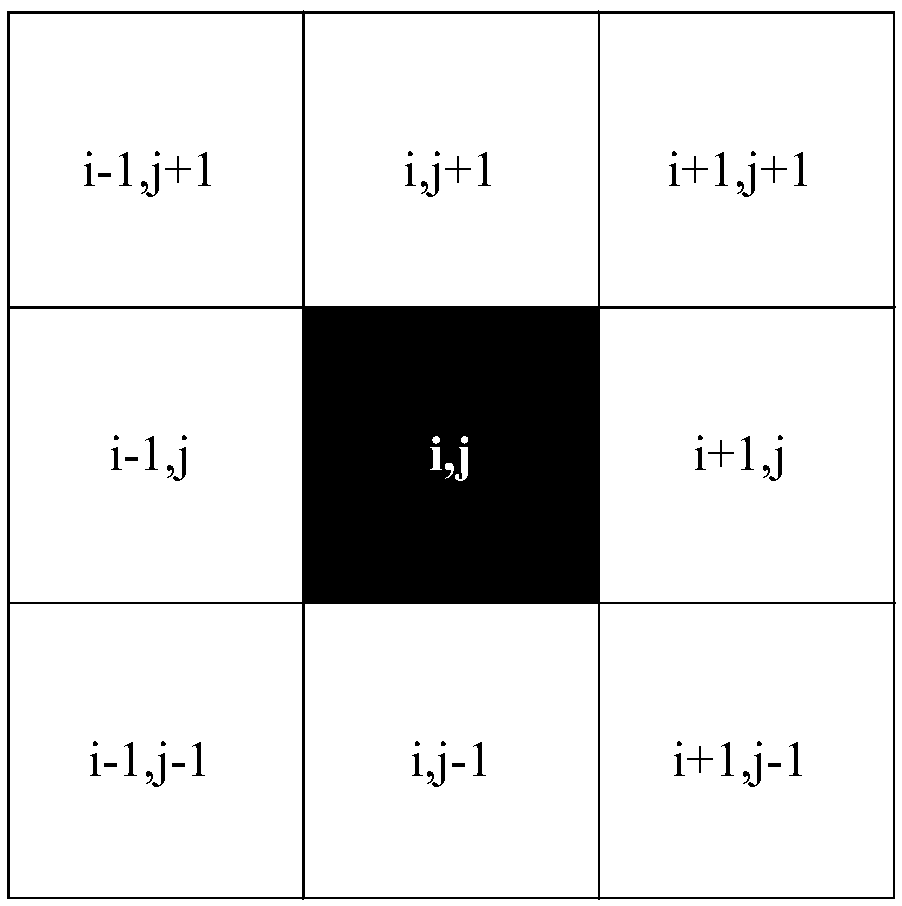

[0062] Step 1: Acquisition of physical property parameters. Obtain the thermodynamic parameters, solute diffusion parameters and nucleation parameters required for calculation from the on-site continuous casting workshop and related literature on dendrite growth. The thermodynamic parameters include thermal subcooling, liquidus slope, Solute diffusion parameters include gas constant, solute equilibrium partition coefficient, solid phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com