Asphalt flame-retardant viscosity reducer and preparation method thereof

A technology of viscosity reducer and flame retardant additive, which is applied in the direction of building components, building insulation materials, construction, etc., and can solve the problems of reducing asphalt mixture mixing, paving, rolling temperature, reducing construction temperature, and reducing asphalt viscosity. Achieve the effects of improving high temperature performance, reducing construction temperature, and reducing asphalt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

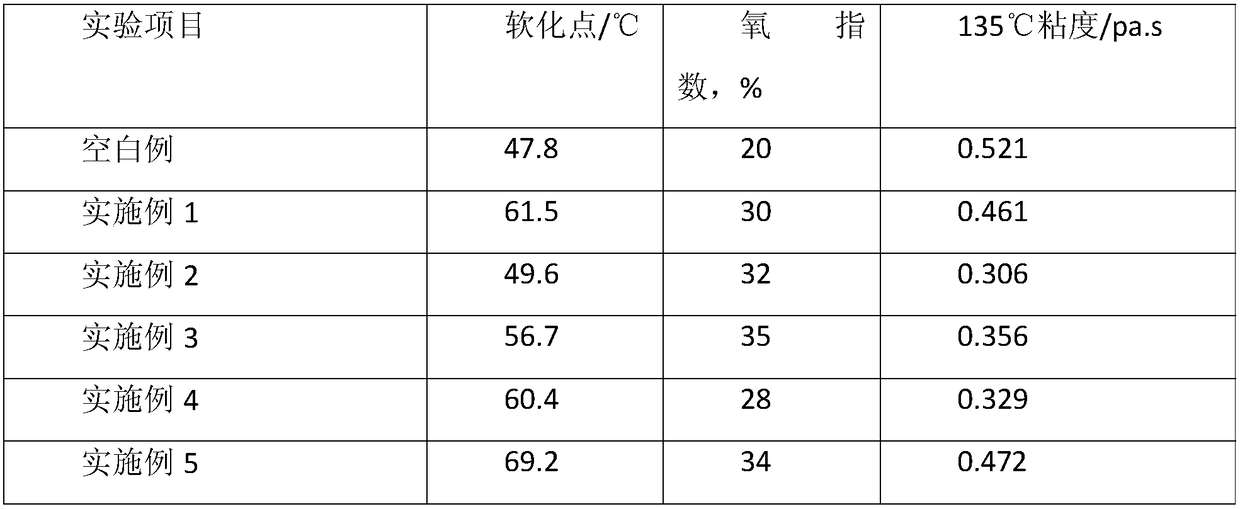

Examples

Embodiment 1

[0028] The preparation method of asphalt flame retardant viscosity reducer, the steps are as follows:

[0029] Heat 1.5 parts of chlorinated paraffin to melt, add 6 parts of polyethylene, 2 parts of aluminum hydroxide and stir at a constant temperature of 165°C for 20 minutes, then add 2 parts of stearic acid and stir at a constant temperature for 5 minutes to granulate.

Embodiment 2

[0031] The preparation method of asphalt flame retardant viscosity reducer, the steps are as follows:

[0032] Heat 2.5 parts of chlorinated paraffin until melted, add 1 part of polyethylene, 1 part of coumarone resin and 2 parts of expandable graphite, stir at 160°C for 10 minutes, then add 3 parts of stearic acid and stir for 5 minutes to granulate Can.

Embodiment 3

[0034] The preparation method of asphalt flame retardant viscosity reducer, the steps are as follows:

[0035] Heat 2 parts of chlorinated paraffin to melt, add 3 parts of polyethylene, 2 parts of coumarone resin, 3 parts of expandable graphite and 4 parts of magnesium hydroxide and stir at 165°C for 15 minutes, then add 2 parts of stearic acid at constant temperature Stir for 5 minutes to granulate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com