Device for detecting pressure of water in concrete pipe

A detection device, concrete pipe technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instruments, etc., can solve the problems of heavy operation of detection device, heavy pipe body, time-consuming and labor-intensive, etc., to promote health The effect of developing, ensuring the test effect and shortening the test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

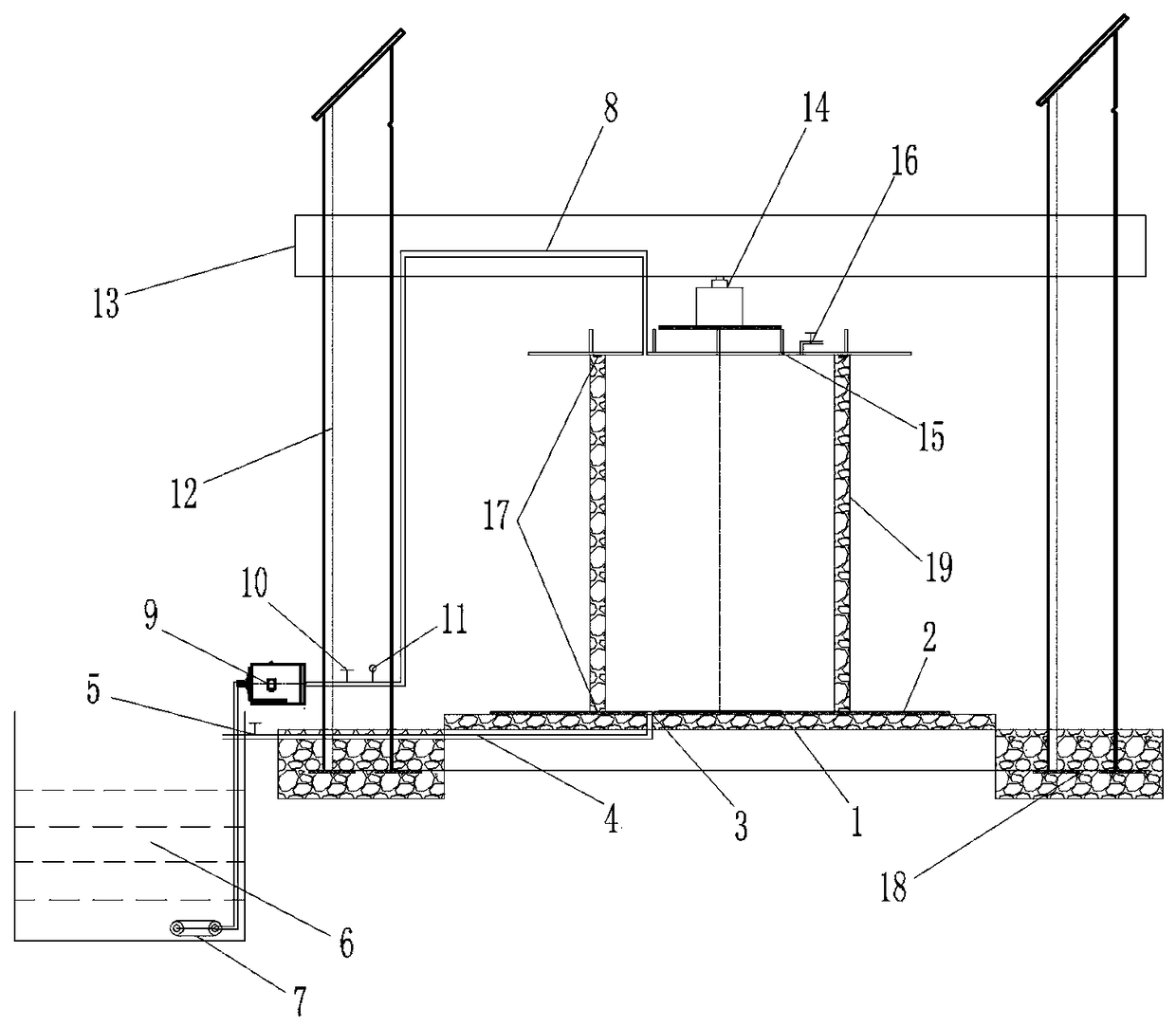

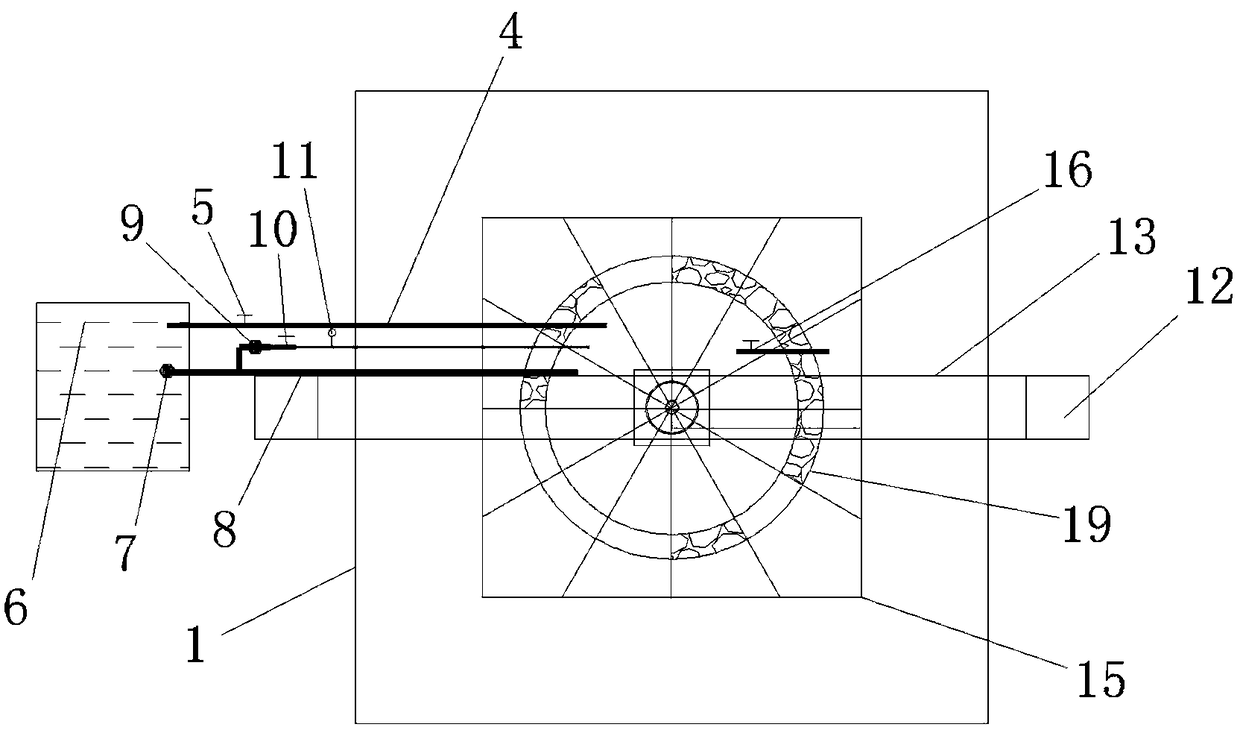

[0019] Embodiment 1: as Figure 1-3 The water pressure detection device in the concrete pipe shown is composed of two parts. The first part is the pipe base system, including steel column 12, steel column 12 foundation, steel beam 13, device cap 1, plugging device 15, rubber seal Circle 17, concrete pipe, jack 14 totally eight members. The second part is the device frame, which is stabilized by the steel column 12, the foundation of the steel column 12, the steel beam 13 and the device platform 1 to ensure the safety and stability of the detection process; the blocking device 15 is composed of two horizontal steel plates and ribbed steel plates The structure is specially customized to ensure that the plugging equipment does not deform and does not leak air; the jack 14 acts on the plugging device 15 through the reverse force of the steel beam 13, and squeezes the seam between the pipe and the steel plate to the minimum, and the role of the rubber sealing ring 17 In order to e...

Embodiment 2

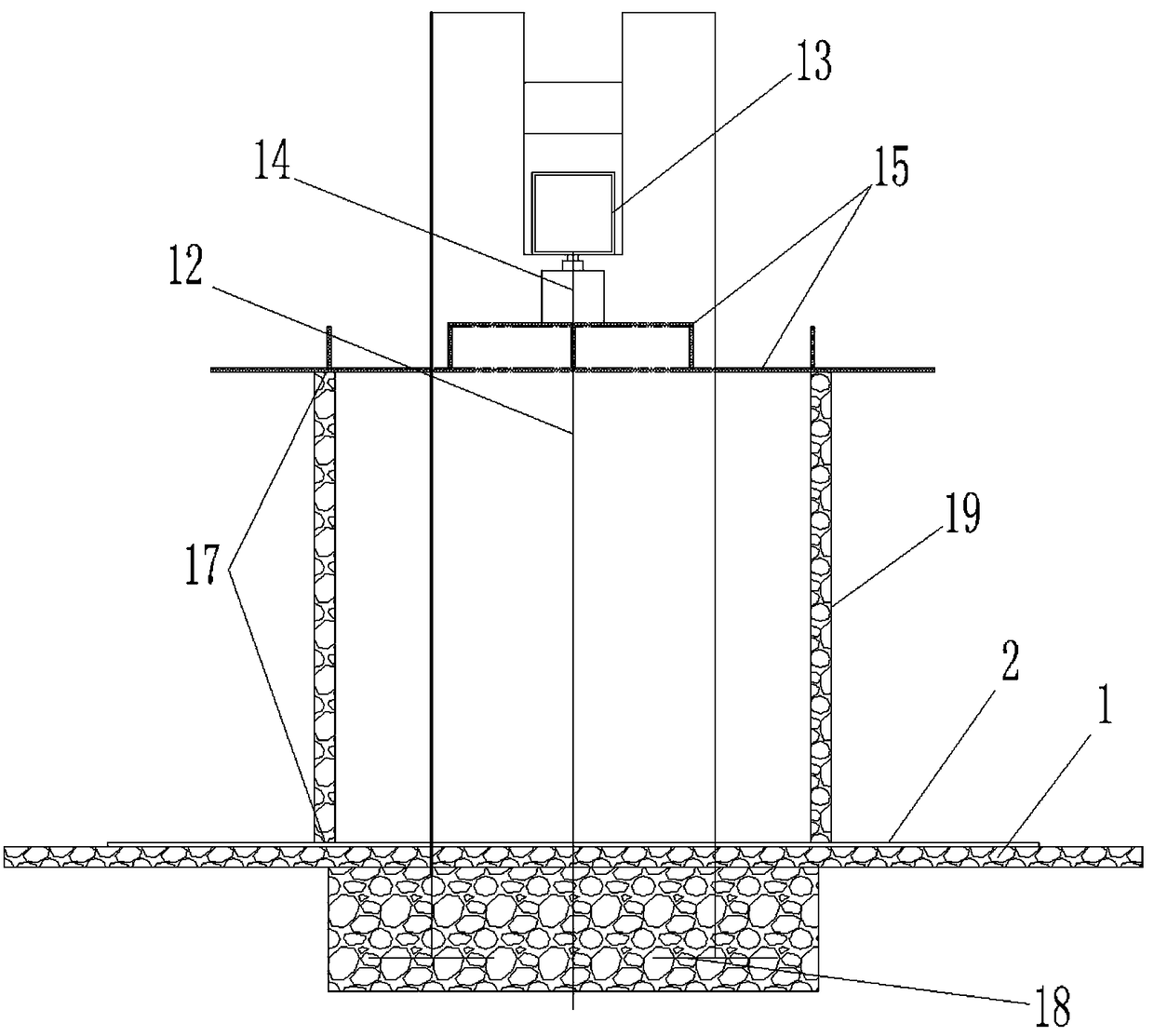

[0026] Embodiment 2: another kind of water pressure detection device in concrete pipes, including bearing mechanism and high-pressure water supply mechanism, etc., such as figure 1 with figure 2 The bearing mechanism shown includes a column foundation 18 , a device platform 1 and a platform steel liner 2 . Wherein, the bearing platform 1 of the device and the steel lining plate 2 of the bearing platform are compounded to form a bearing platform of the reinforced concrete pipe 19, and the column foundation 18 is located at symmetrical positions on both sides of the bearing platform.

[0027] The upper side of each side column foundation 18 is fixed with a steel column 12, and the tops of the steel columns 12 on both sides are distributed with sockets and fitted with a rear steel beam 13, and the lower center of the steel beam 13 is vertically connected with a jack 14, and the lower end of the jack 14 is connected with a The plugging device 15 is provided with an exhaust hole ...

Embodiment 3

[0033] Embodiment 3: on the basis of embodiment 2, the rubber seal ring adopted is an annular rubber air bag. At this time, the upper and lower rubber air bags are provided with inflation valves, and the upper and lower rubber air bags contact the reinforced concrete pipe 19 up and down and are filled by inflation. The inner and outer sides of the upper and lower ends of the reinforced concrete pipe 19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com