Analysis method for submillimeter-scale defects on the surface of coating materials

A sub-millimeter-level defect analysis technology, which is applied in the direction of material analysis, material analysis, and optical testing of defects/defects using wave/particle radiation. Small problems, to achieve the effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

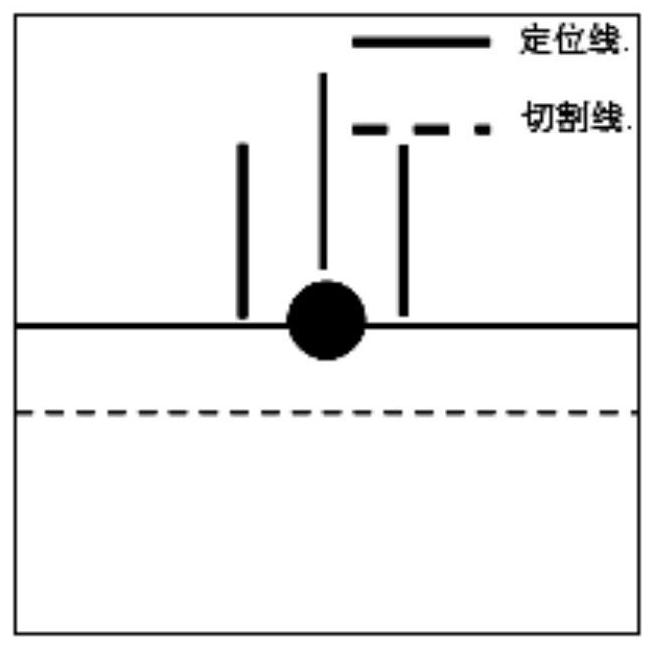

[0037] A method for analyzing submillimeter defects on the surface of a coating material, comprising the steps of:

[0038] 1) Sample preparation and macroscopic observation

[0039] 1a) Sample preparation: centering on the defect, cut the sample to be analyzed into a sample of 20mm×20mm×thickness (≤10mm). If the size of the sample to be analyzed is small, no cutting is required;

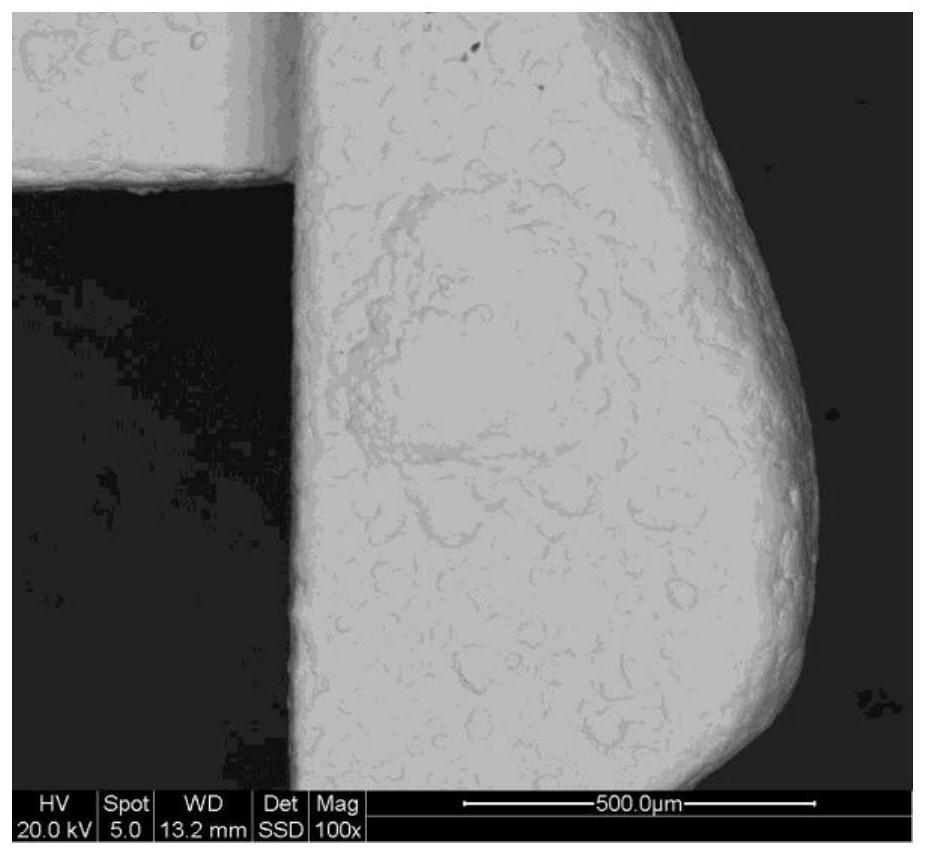

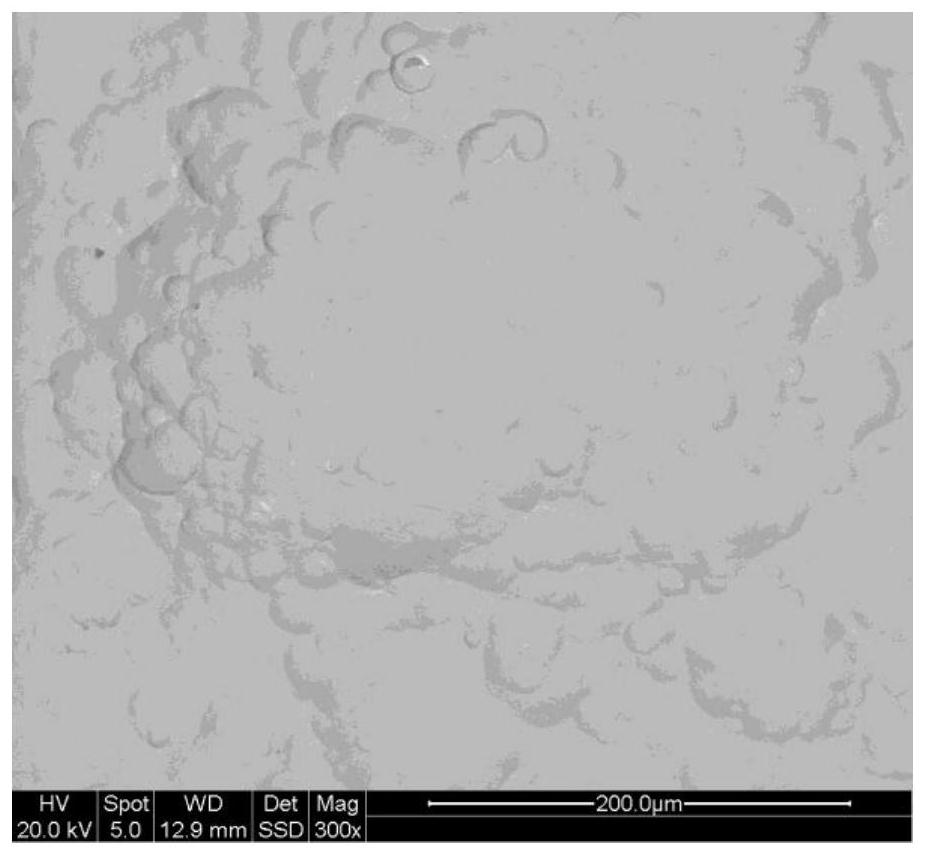

[0040] 1b) Macroscopic observation: After the sample is placed in an alcohol solution for ultrasonic cleaning, use an optical microscope to observe and take pictures of submicron defects on the coating surface of the sample map, and record the optical features of the defect, such as length, width, Whether the surface is convex or concave, etc....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com