Method for producing printed wiring board and protective film

A technology for a printed wiring board and a manufacturing method, which is applied in the manufacturing of printed circuits, printed circuits, and multilayer circuits, etc., can solve the problems of large difference in thermal expansion coefficient, inability to fully ensure temperature cycle reliability, and large thermal expansion coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

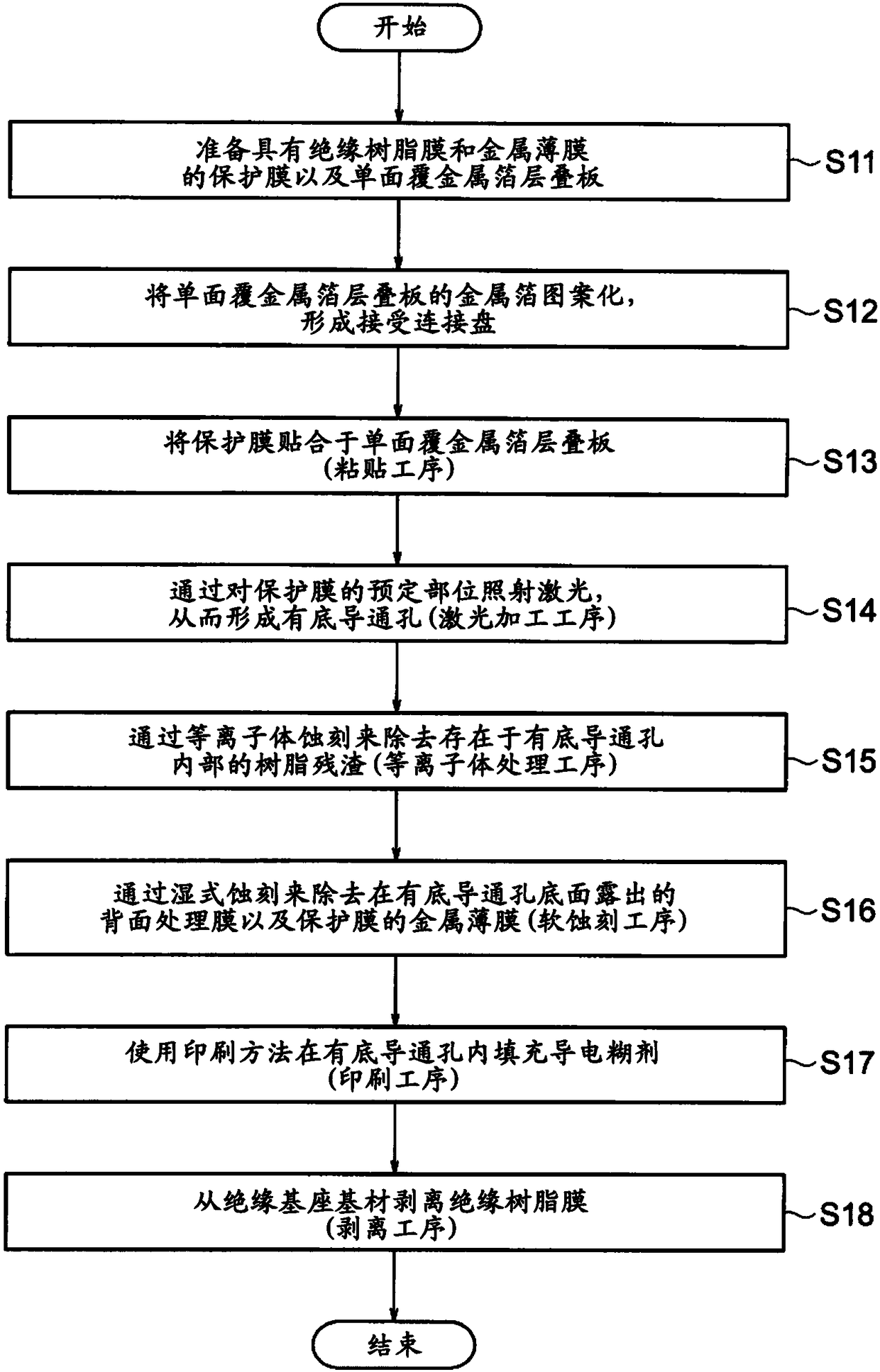

[0101] In the method of manufacturing a printed wiring board according to the first embodiment of the present invention, along figure 1 The flow chart is described. In this embodiment, a single-sided metal foil-clad laminate is used as a starting material.

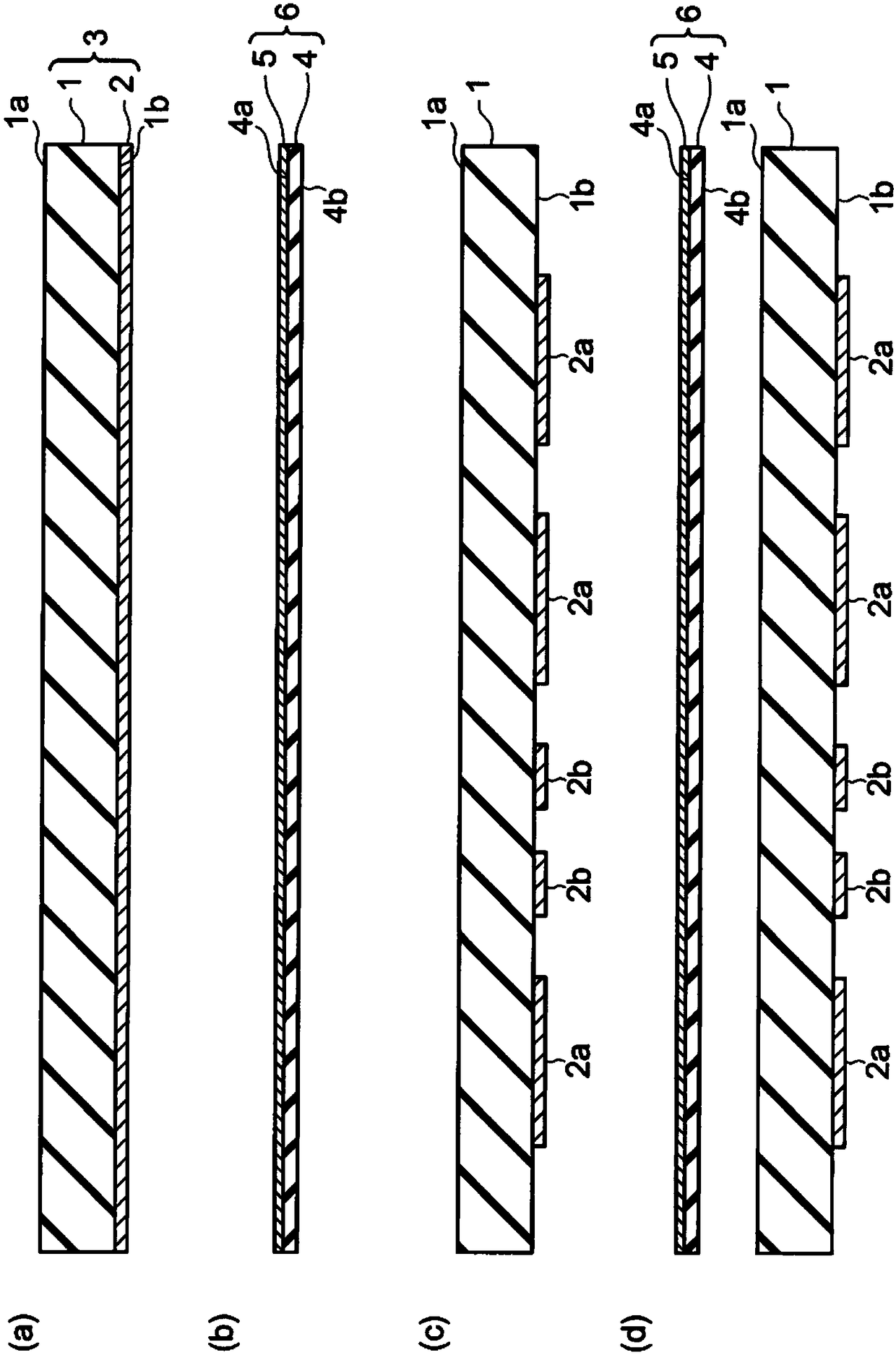

[0102] First, the single-sided metal foil-clad laminate 3 and the protective film 6 are prepared (step S11). Such as figure 2 As shown in (a), the single-sided metal foil-clad laminate 3 has an insulating base material 1 and a metal foil 2 (first metal foil) formed on one side of the insulating base material 1 . The insulating base material 1 has a main surface 1a (first main surface) and a main surface 1b (second main surface) opposite to the main surface 1a. In this embodiment, the main surface 1 a is the upper surface of the insulating base material 1 , and the main surface 1 b is the lower surface of the insulating base material 1 .

[0103] The insulating base material 1 is, for example, an insulating film forme...

no. 2 approach

[0141]In the method of manufacturing a printed wiring board according to the second embodiment of the present invention, along Image 6 The flow chart is described. In this embodiment, a double-sided metal foil-clad laminate is used as a starting material.

[0142] First, the double-sided metal foil-clad laminate 24 and the protective film 6 are prepared (step S21). Such as Figure 7 As shown in (a), the double-sided metal foil-clad laminate 24 has an insulating base material 21, a metal foil 22 (first metal foil), and a metal foil 23 (second metal foil). The insulating base material 21 has a main surface 21a (first main surface) and a main surface 21b (second main surface) opposite to the main surface 21a. In this embodiment, the main surface 21 a is the upper surface of the insulating base material 21 , and the main surface 21 b is the lower surface of the insulating base material 21 .

[0143] The insulating base material 21 is, for example, an insulating film formed of...

no. 3 approach

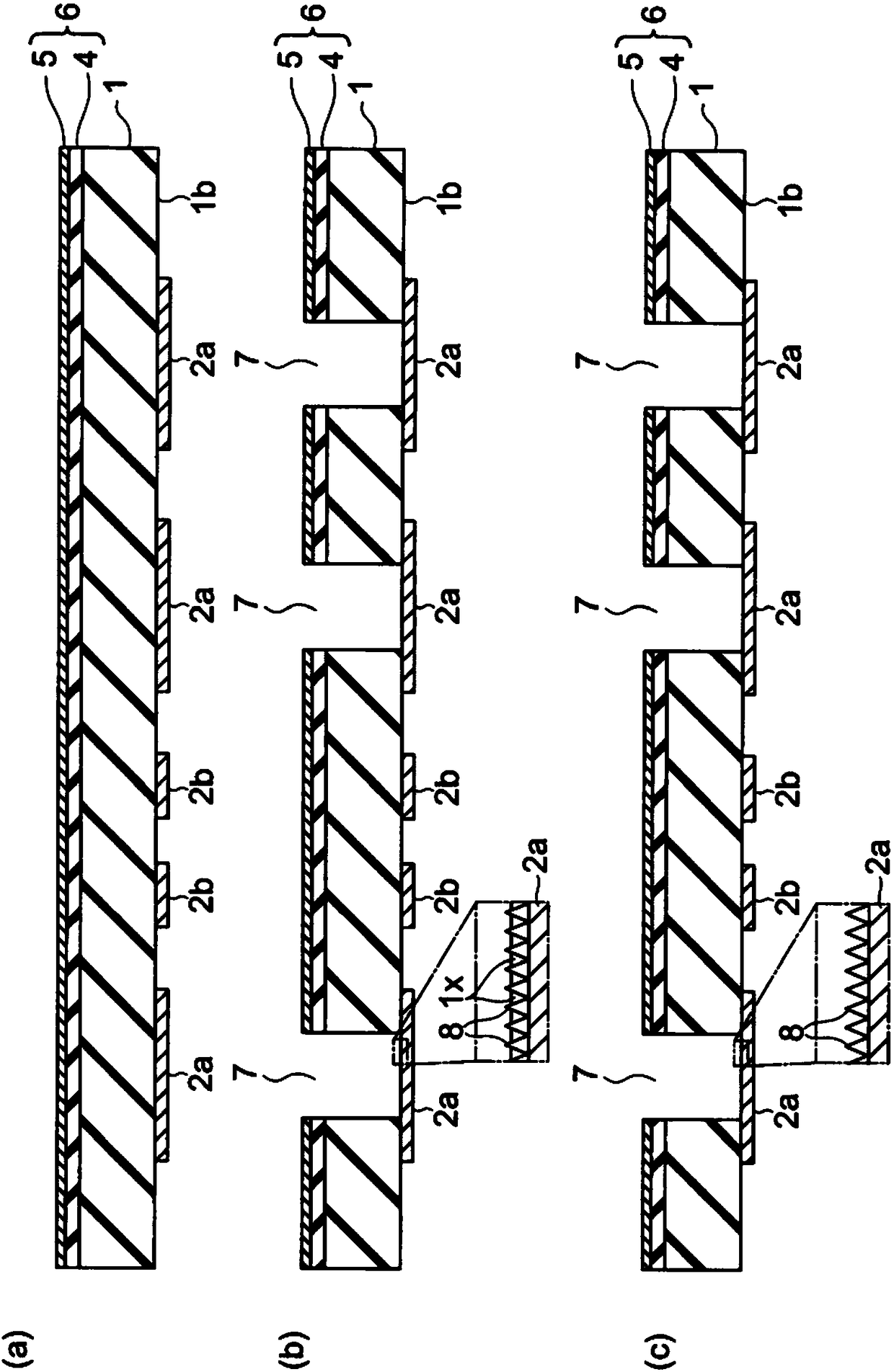

[0162] In the method of manufacturing a printed wiring board according to the third embodiment of the present invention, along Figure 10 The flow chart is described. In this embodiment, a multilayer printed wiring board is produced using the wiring base material 10 produced in the first embodiment and the wiring base material 30 produced in the second embodiment as starting materials.

[0163] First, the wiring base material 10 and the wiring base material 30 are prepared (step S31). Such as Figure 4 As shown, the wiring base material 10 has the protrusion part 9a obtained in the peeling process (process S18 of 1st Embodiment). Such as Figure 9 As shown, the wiring base material 30 has the protrusion part 27a obtained in the peeling process (process S29 of 2nd Embodiment).

[0164] Next, if Figure 11 As shown, the wiring base material 10 and the wiring base material 30 are aligned and stacked so that the protruding portion 9a and the protruding portion 27a are in cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com