Spraying and scattering tower device

A spray pipe and tower body technology, which is applied in the field of waste gas treatment equipment, can solve the problems of large resistance of the diffuser tube insertion depth system, the depth of the diffuser tube insertion depth in the flue gas corridor, and low desulfurization and dust removal efficiency, so as to reduce the risk of scaling , increase the residence time, weaken the effect of scouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

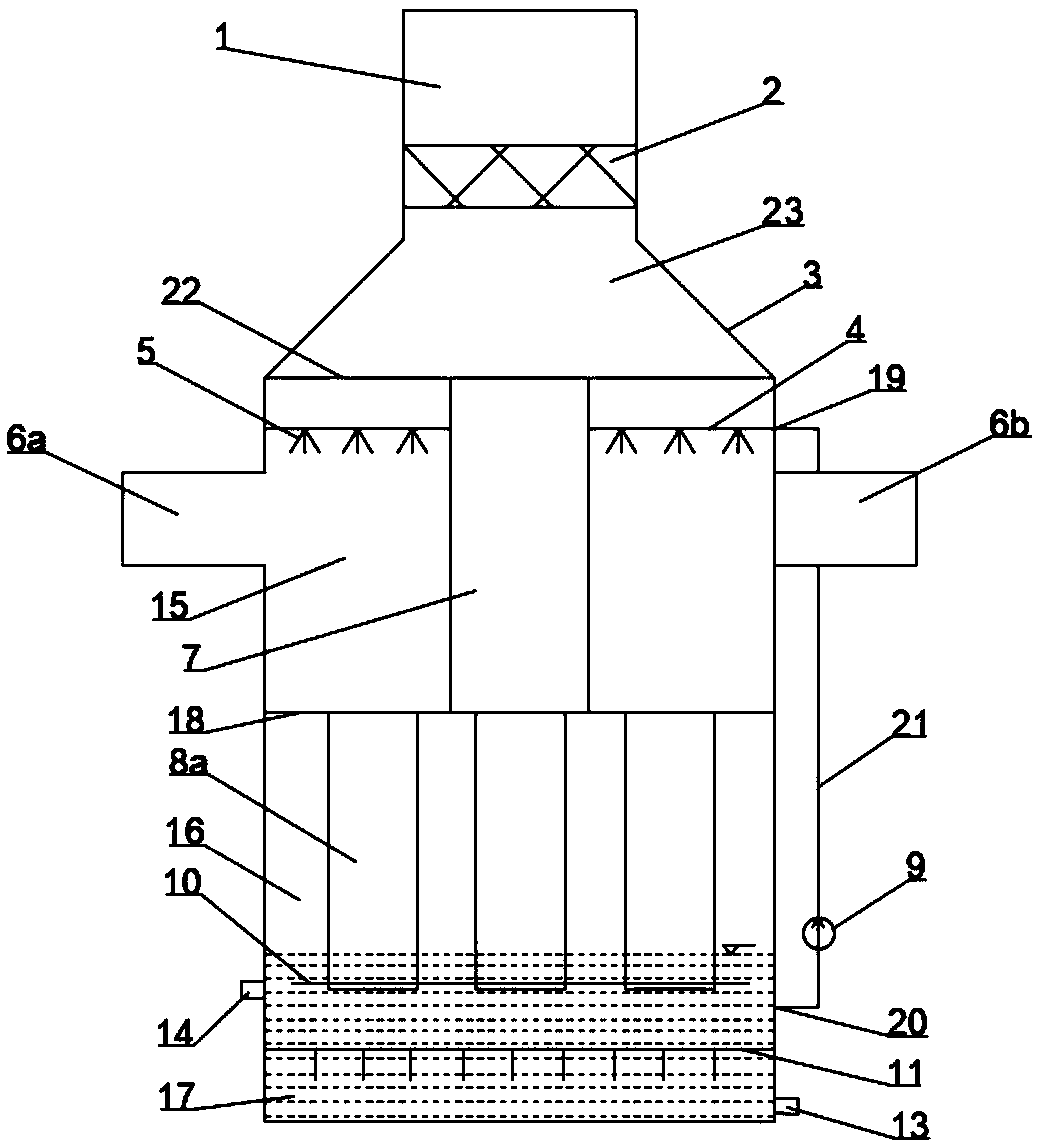

[0024] Such as figure 1 and figure 2 As shown, a spray scattering tower device includes an outlet flue 1 and a cylindrical tower body 3, with the outlet flue 1 as the upper end, and is set between the outlet flue 1 and the cylindrical tower body 3 Demister 2, and the three are connected;

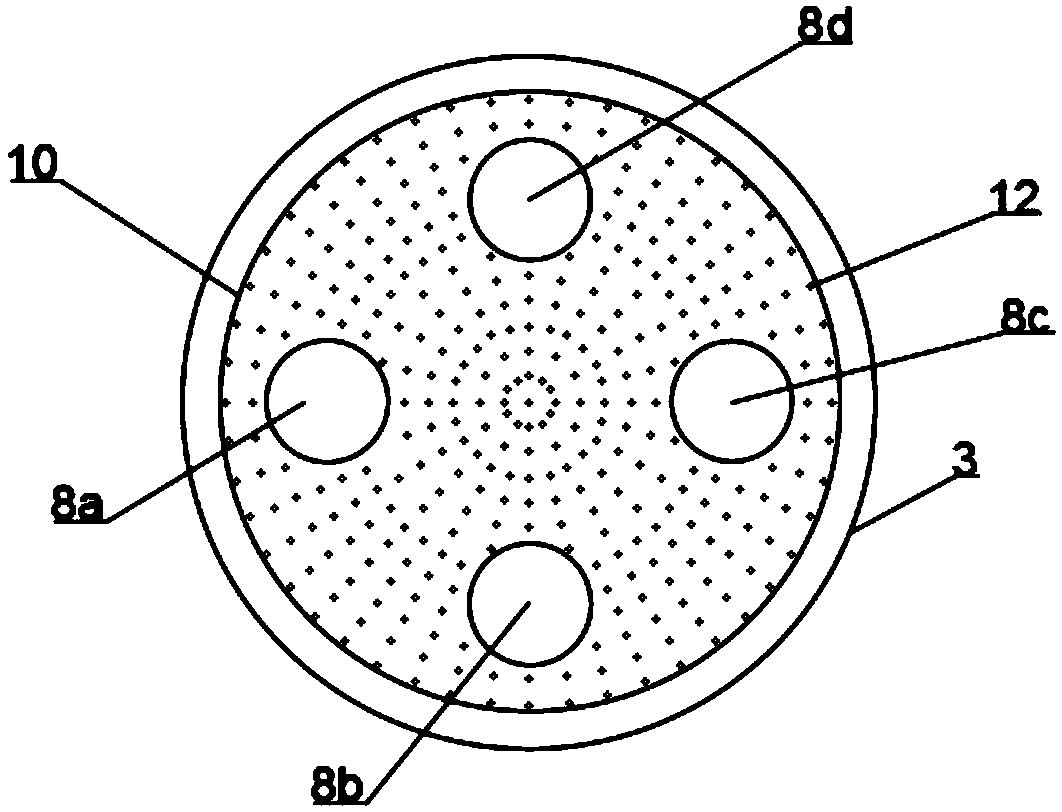

[0025] The interior of the cylindrical tower body 3 includes an upper bin 23, a spraying middle bin 15, a bubbling lower bin 16, and a slurry pool 17 at the bottom; An upper isolation baffle 22 and a lower isolation baffle 18 are respectively arranged between them, and these two baffles are sealed and connected with the periphery of the cylindrical tower body 3; The first inlet flue 6a and the second inlet flue 6b are horizontally arranged opposite each other, and the spray pipe 4, the nozzle 5, and the ascending flue 7 coaxial and in the center are arranged inside the spray chamber 15; The isolating baffle 22 and the lower isolating baffle 18 are sealed and connected with the ascending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com