High hydrothermal stability MOFs catalyst, preparation method of MOFs (Metal Organic Framework) catalyst, and method for preparing chemical product through conversion of cellulose

A technology of thermal stability and catalyst, applied in the field of high hydrothermal stability MOFs catalyst, cellulose conversion preparation chemicals, preparation field, can solve the problems of depletion of fossil resources, low physical and chemical stability of MOFs, etc. Activity and good type-selective catalytic performance, the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

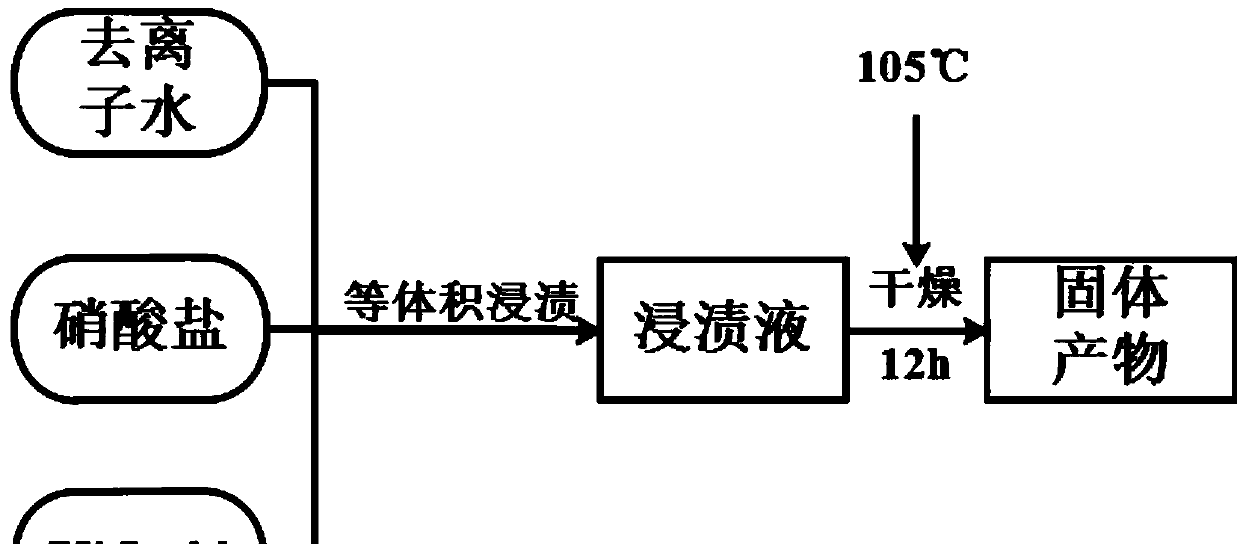

Method used

Image

Examples

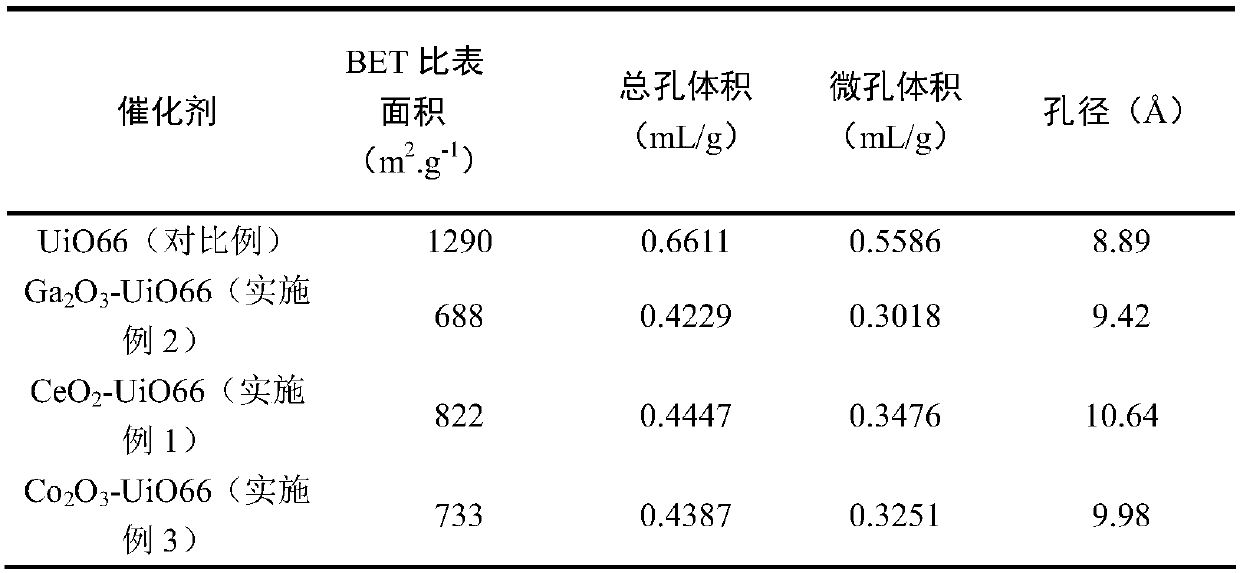

Embodiment 1

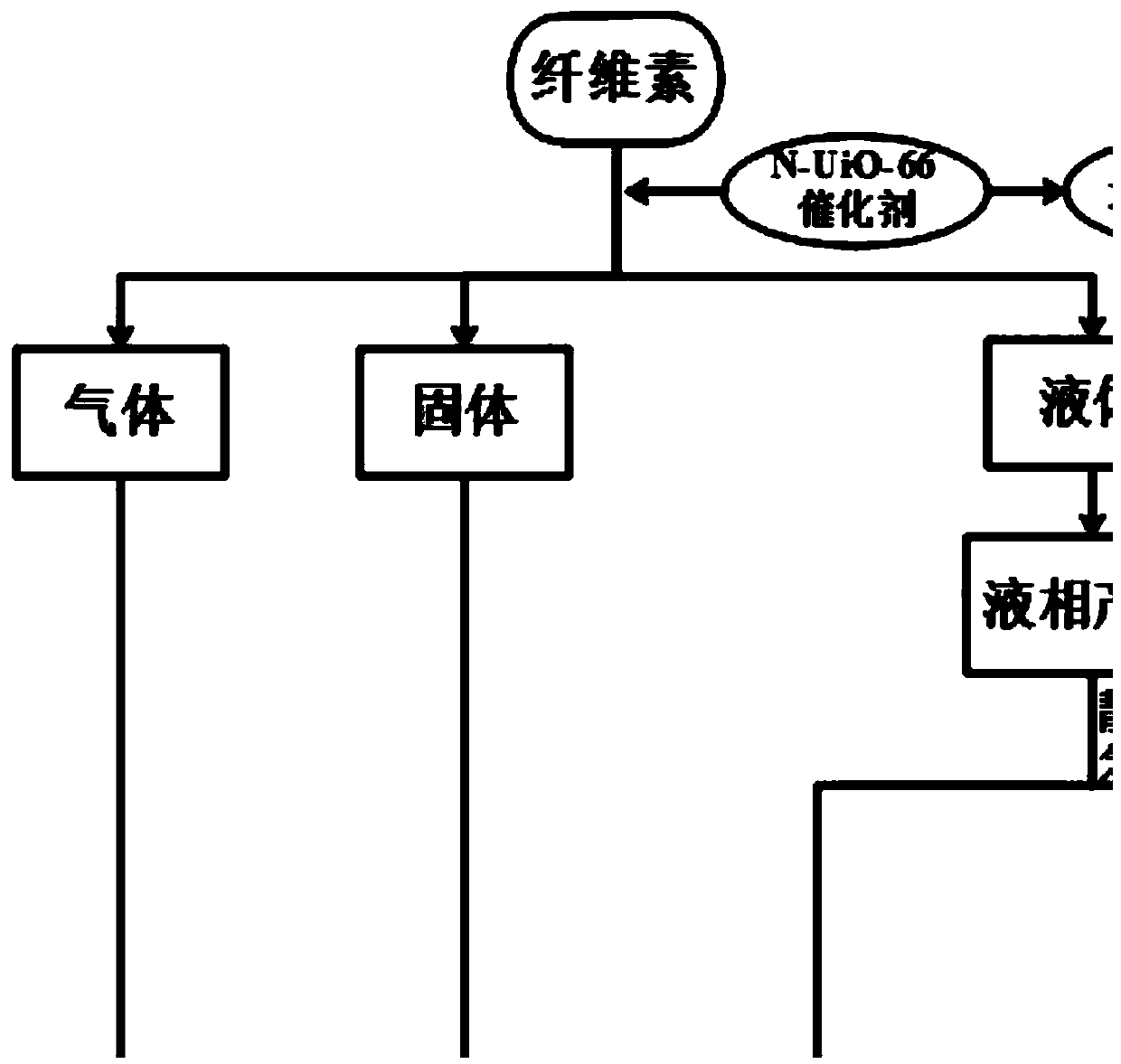

[0039] Weigh 5g of cellulose sample, 0.125g of catalyst and 50mL of deionized water into the reactor according to the ratio of solid to liquid of 10:1, the amount of catalyst added is 2.5% of the cellulose, and the metal organic framework compound catalyst is CeO 2 -UiO-66, the hydrothermal conversion temperature is 240°C; the reaction time is 6h, and the cellulose conversion rate is 77.08%. The relative content of aldehyde products such as furfural and cinnamaldehyde in the catalytic conversion products is 41.75%, and the relative content of acid compounds such as lactic acid and levulinic acid in the water-soluble products is 88.66%.

Embodiment 2

[0041] Weigh 5g of cellulose sample and 0.125g of catalyst and 50mL of deionized water into the reactor according to the ratio of solid to liquid of 10:1. 2 o 3 -UiO-66, the hydrothermal conversion temperature is 240°C; the reaction time is 6h, and the cellulose conversion rate is 79.59%. The relative content of aldehyde products such as furfural and cinnamaldehyde in the catalytic conversion products is 40.87%, and the relative content of acid compounds such as lactic acid and levulinic acid in the water-soluble products is 94.82%.

Embodiment 3

[0043] Weigh 5g of cellulose sample, 0.125g of catalyst and 50mL of deionized water into the reactor according to the solid-liquid ratio of 10:1. 2 o 3 -UiO-66, the hydrothermal conversion temperature is 240°C; the reaction time is 6h, and the cellulose conversion rate is 78.31%. The relative content of aldehyde products such as furfural and cinnamaldehyde in the catalytic conversion products is 39.02%, and the relative content of acid compounds such as lactic acid and levulinic acid in the water-soluble products is 95.68%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com