Flotation method for phosphate ore

A phosphate rock and ore grinding technology, applied in flotation, solid separation, etc., can solve problems such as environmental pollution, corrosion of metal waste in the flotation system, and achieve the effects of reducing the use of sulfuric acid, saving money, and solving scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

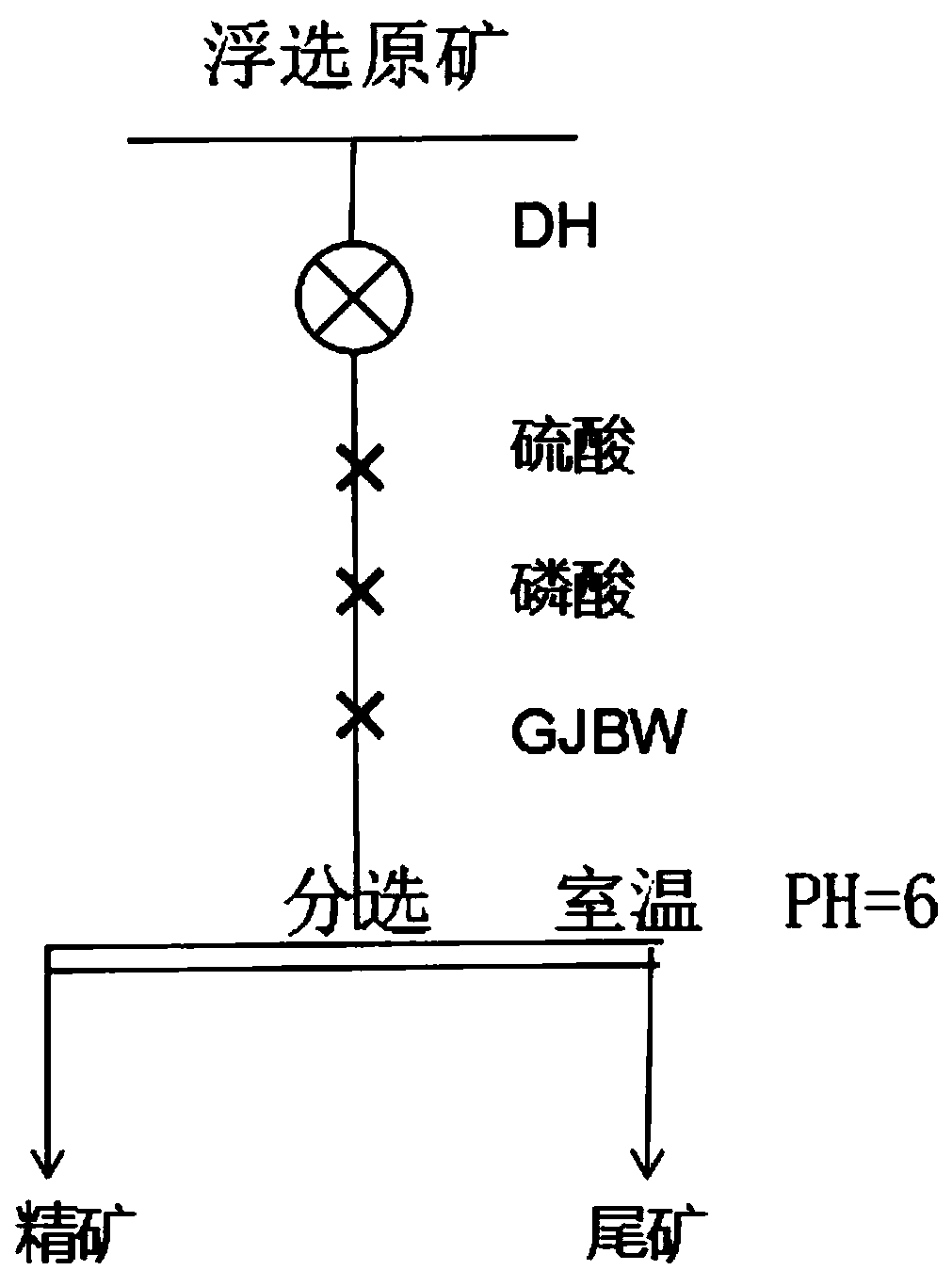

[0016] Embodiment 1: as figure 1 Shown, a kind of flotation method of phosphate rock, this method may further comprise the steps:

[0017] (1) Crush the raw ore calcium-magnesium low-grade phosphate rock, put the crushed product into the ball mill, add sodium fluoride and tap water into the ball mill until the grinding concentration is 60% for grinding, control the grinding time, and grind until the particle size is less than 0.074 The mass fraction of ore particles in mm accounts for 75%, and the amount of sodium fluoride relative to the raw ore is 1.38kg / t;

[0018] (2) Control the temperature in a normal temperature environment, add tap water to adjust the pulp to a solid concentration of 300g / L, add a pH regulator sulfuric acid to the pulp, stir, and adjust the pH of the pulp to 6;

[0019] (3) Add the inhibitor and stir. The inhibitor is phosphoric acid, and the dosage is 7.8kg / t relative to that of the raw ore;

[0020] (4) Then add reverse flotation collector GJBW and...

Embodiment 2

[0023] Embodiment 2: as figure 1 Shown, a kind of flotation method of phosphate rock, this method may further comprise the steps:

[0024] (1) Crush the raw ore calcium-magnesium low-grade phosphate rock, put the crushed product into the ball mill, add sodium fluoride and tap water into the ball mill until the grinding concentration is 60% for grinding, control the grinding time, and grind until the particle size is less than 0.074 The mass fraction of ore particles in mm accounts for 75%, and the amount of sodium fluoride relative to the raw ore is 1.42kg / t;

[0025] (2) Control the temperature in a normal temperature environment, add tap water to adjust the pulp to a solid concentration of 300g / L, add a pH regulator sulfuric acid to the pulp, stir, and adjust the pH of the pulp to 6;

[0026] (3) Add the inhibitor and stir. The inhibitor is phosphoric acid, and the dosage is 8.2kg / t relative to that of the raw ore;

[0027] (4) Then add reverse flotation collector GJBW and...

Embodiment 3

[0030] Embodiment 3: as figure 1 Shown, a kind of flotation method of phosphate rock, this method may further comprise the steps:

[0031] (1) Crush the raw ore calcium-magnesium low-grade phosphate rock, put the crushed product into the ball mill, add sodium fluoride and tap water into the ball mill until the grinding concentration is 60% for grinding, control the grinding time, and grind until the particle size is less than 0.074 The mass fraction of ore particles in mm accounts for 75%, and the amount of sodium fluoride relative to the raw ore is 1.40kg / t;

[0032] (2) Control the temperature in a normal temperature environment, add tap water to adjust the pulp to a solid concentration of 300g / L, add a pH regulator sulfuric acid to the pulp, stir, and adjust the pH of the pulp to 6;

[0033] (3) Add the inhibitor and stir. The inhibitor is phosphoric acid, and the dosage is 8kg / t relative to that of the raw ore;

[0034] (4) Then add reverse flotation collector GJBW and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com