Method for manufacturing straw board

A straw board, crop straw technology, applied in the direction of flat products, manufacturing tools, pretreatment of molding materials, etc., to achieve the effects of reducing gaps and air bubbles, controlling warpage deformation, and increasing internal bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

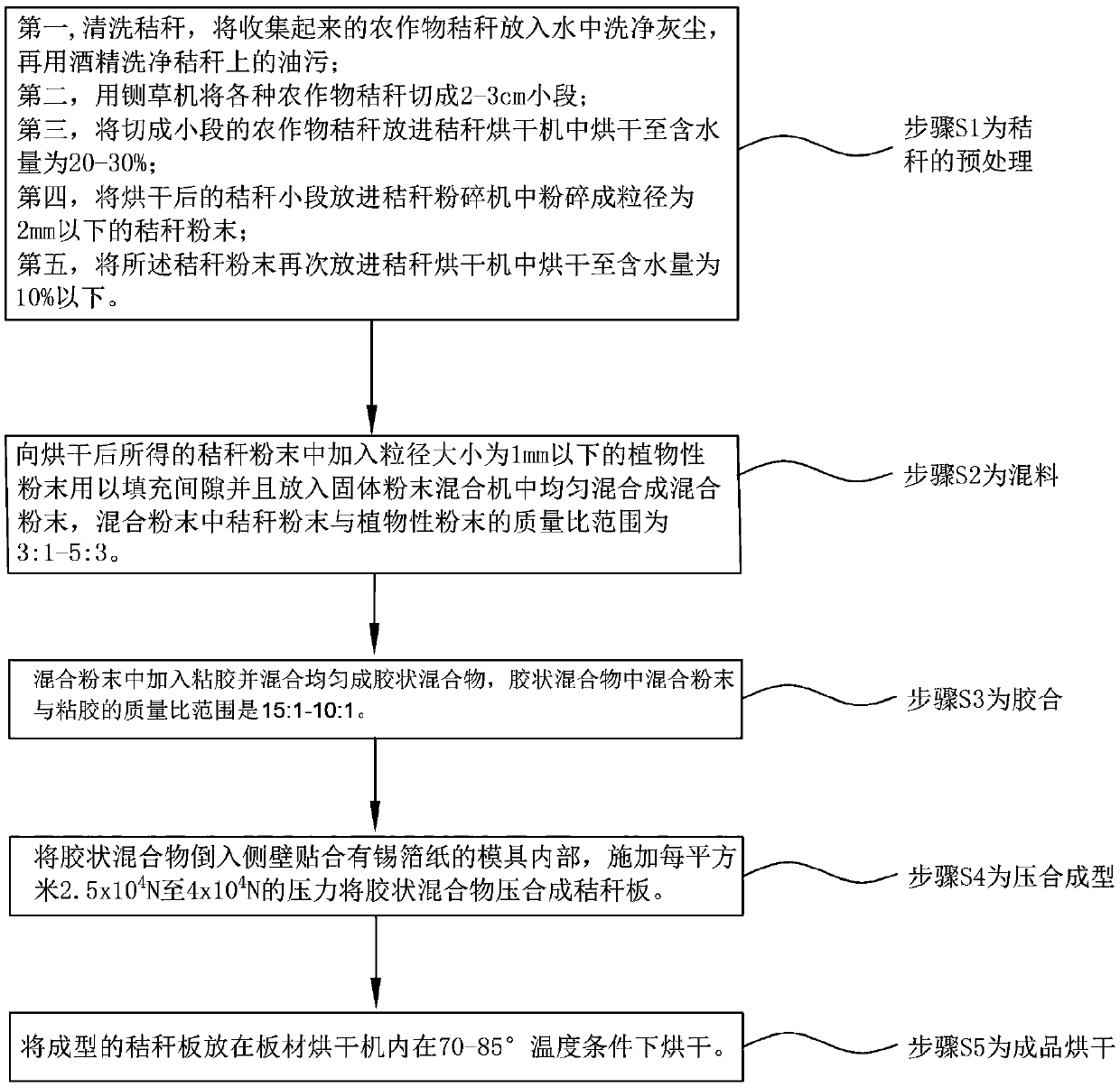

[0032] Such as figure 1 As shown, this embodiment introduces a simple method for making straw boards, which includes the following steps:

[0033] Step S1 is the pretreatment of straw. The pretreatment of straw includes five processes of cleaning, cutting, drying, crushing and drying again. First, crop straw refers to the remaining stems after mature threshing of grasses such as rice, wheat, and corn For the leaf part, put the collected crop stalks into a large pool for multiple times of water soaking to wash the dust on the crop stalks; secondly, use an organic solvent such as alcohol to clean off the oil-soluble dirt on the crop stalks such as grease; , use a hay cutter to cut various crop straws into 2-3cm small pieces; thirdly, put the cut into small pieces of crop straws in a straw dryer and dry them until the moisture content is 20-30%; The dried straw segments are put into a straw grinder and crushed into straw powder; fifthly, the straw powder is put into a straw drye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com