Remote-sensing microsatellite

A micro-satellite and remote sensing technology, applied in the field of micro-satellites, can solve the problem that the satellite cannot be quickly assembled, lightweight, fast maneuvering, the two-stack unfolding solar panels are installed on the ground, and the ground deployment process is complicated, and cannot meet the load carrying capacity of large cameras. and other problems, to achieve the effect of convenient and quick assembly and disassembly, heavy weight and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

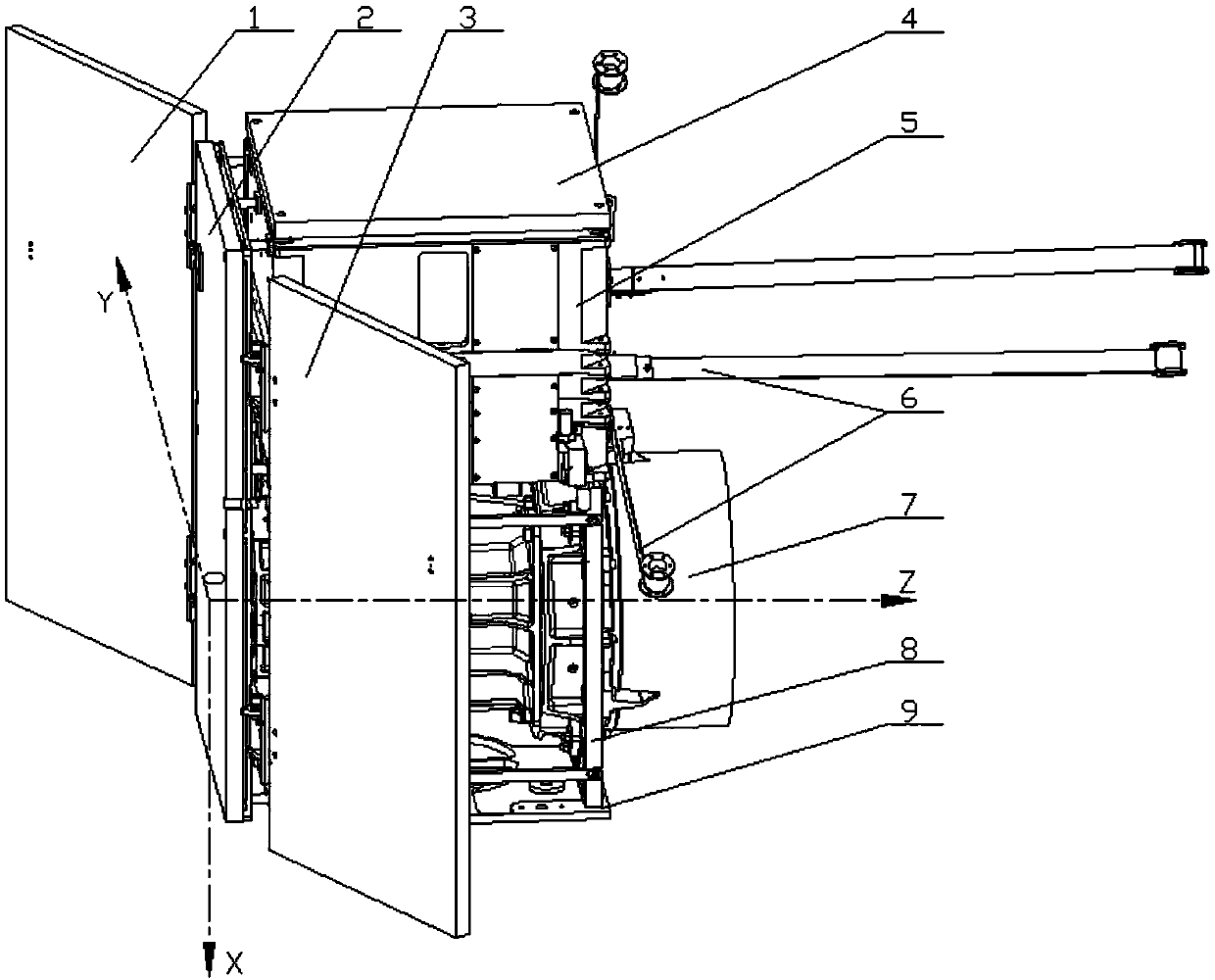

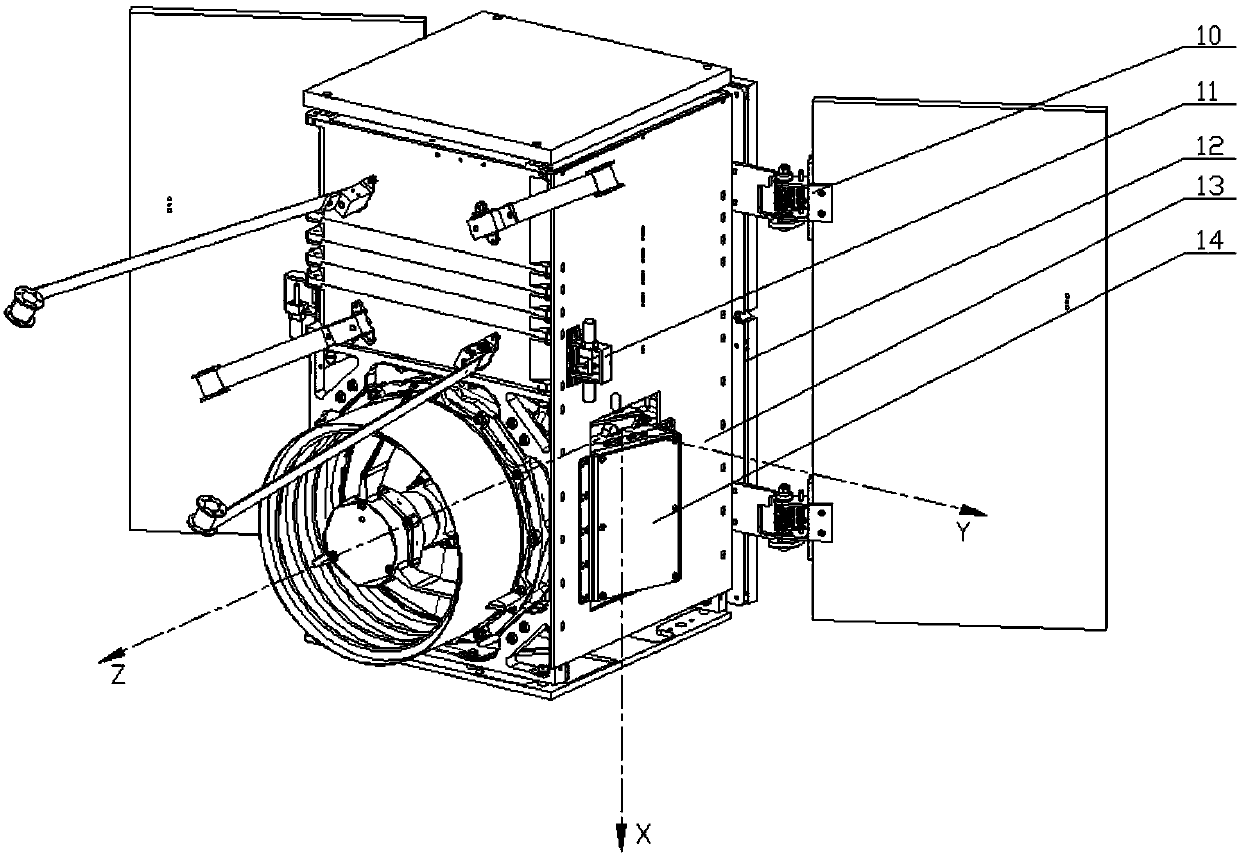

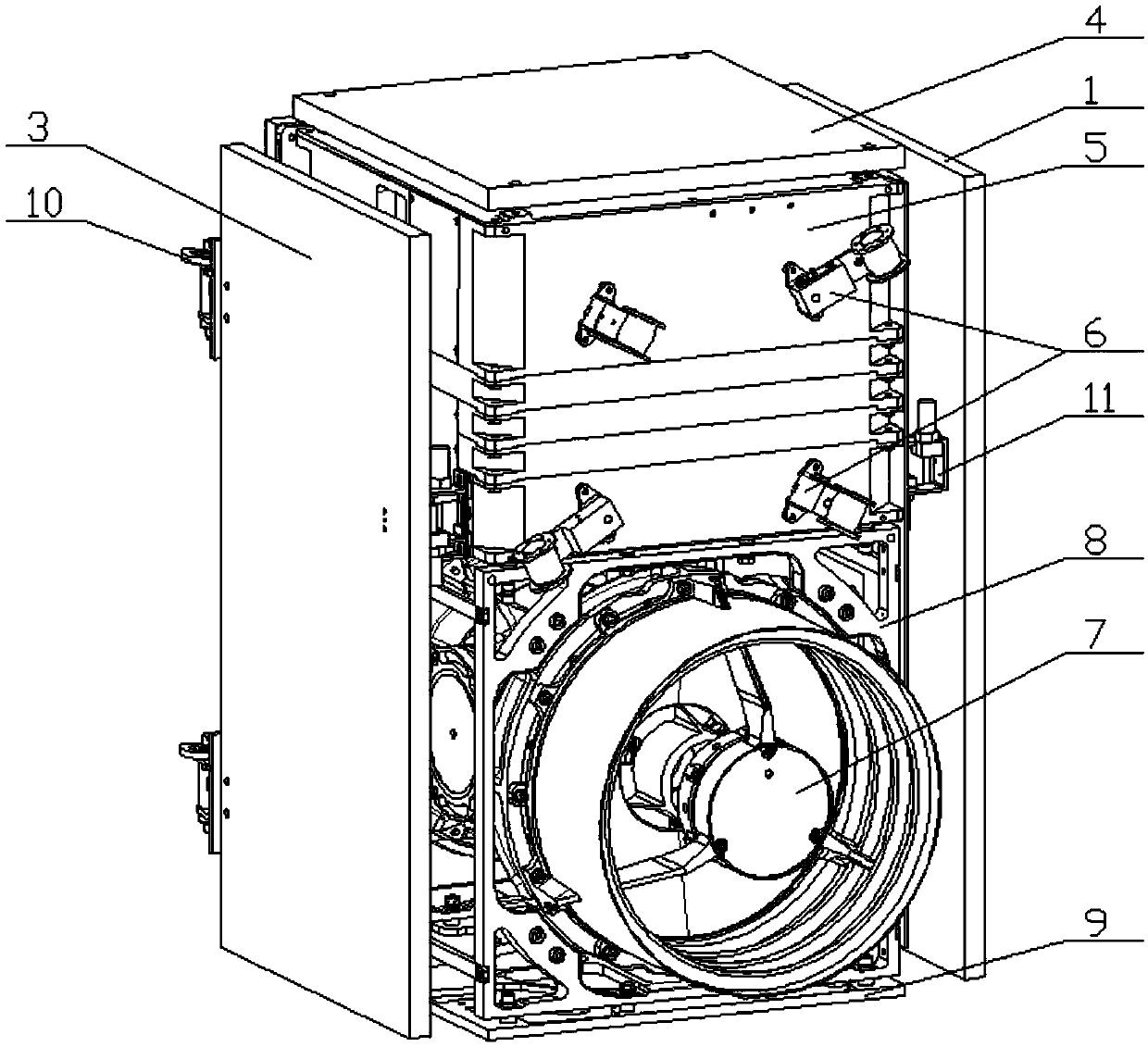

[0049] The present invention is a remote sensing microsatellite, comprising a laminated platform structure 5, a first body-mounted solar sail panel 2, a second body-mounted solar sail panel 4, a first unfolded solar sail panel 1, and a second unfolded solar sail Board 3, load camera 7, load frame 8, bottom plate 9, battery array bracket 12, heat sink 13, electronic cabin heat sink 14, four antennas 6, four hinges 10 and two hot knife brackets 11.

[0050] The load frame 8 is fixed on the bottom of the platform structure 5 by eight screws, and is separated by a polyimide heat-insulating gasket. The load camera 7 is fixed in the load frame 8 by twelve screws, and is separated by a polyimide heat-insulation gasket. separated; the bottom plate 9 is fixed on the bottom of the load frame 8 by eight screws, and is separated by a polyimide heat-insulating gasket; the battery array support 12 is fixed on the -Z side of the platform structure 5 by nine screws, and used Separated by poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com