Hydraulic power unit valve block structure, hydraulic power unit and applied forklift

A technology of hydraulic power unit and valve block, which is applied to engine components, fluid pressure actuating devices, and devices used to relieve pressure on sealing surfaces, etc. The effect of simple and stable adjustment, simple and convenient operation, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

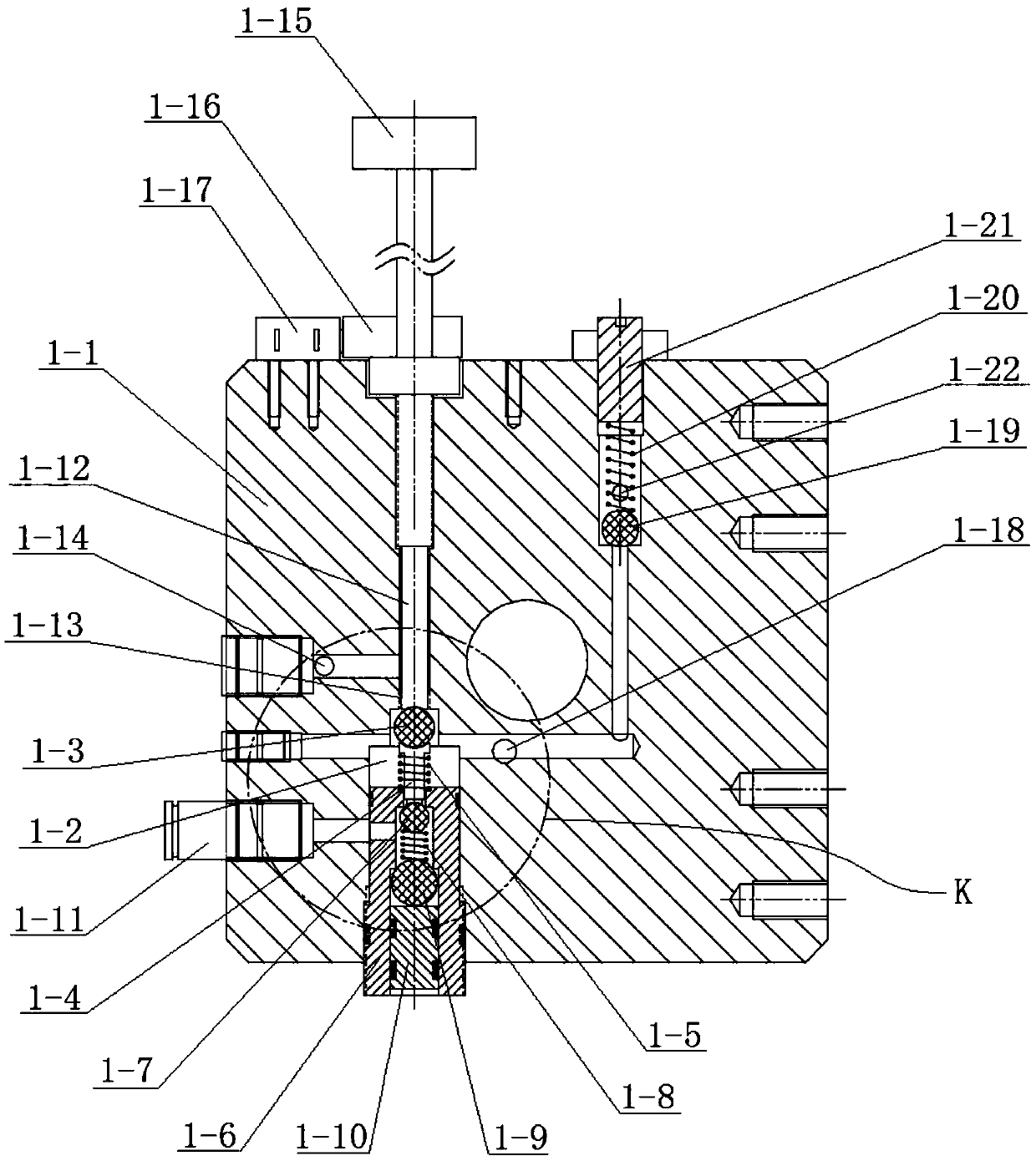

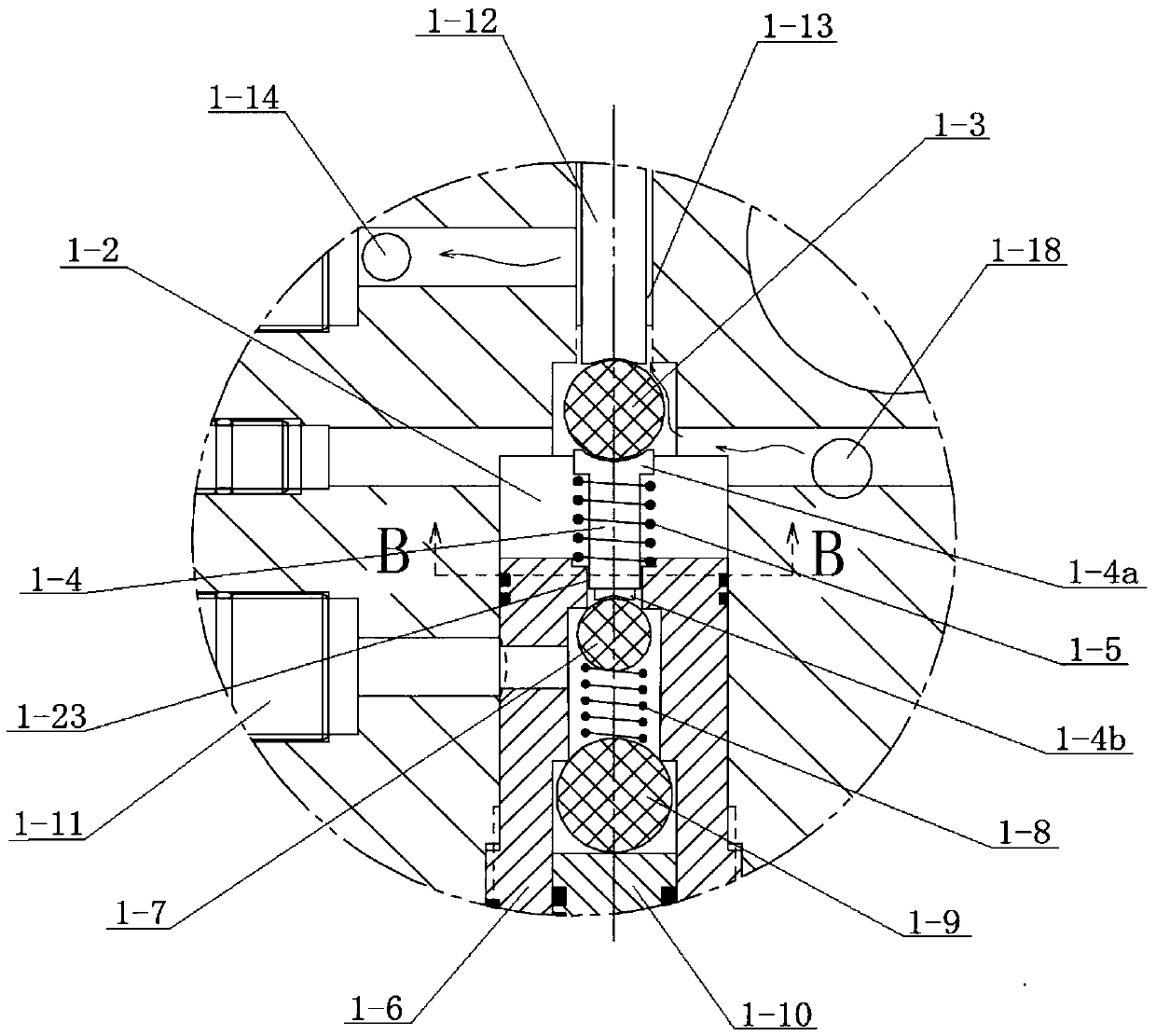

[0040] to combine Figure 2 to Figure 5 As shown, a valve block structure of a hydraulic power unit in this embodiment includes a valve body 1-1, and a first valve core hole 1-2, an oil inlet hole 1-18, and a return valve arranged in the valve body 1-1. The oil hole 1-14, the oil outlet hole and the adjustment mechanism located in the first spool hole 1-2, the adjustment mechanism includes the first adjustment spool, the first spool elastic member 1-5, the spool cover 1- 6. The second regulating spool 1-7, the second spool elastic member 1-8 and the ejector rod 1-12, the oil inlet hole 1-18 communicates with the first valve core hole 1-2, and the ejector rod 1-12 It is installed in the ejector rod hole of the valve body 1-1, and can move telescopically in the ejector rod hole through rotation. Specifically, threaded connection can be used to convert the rotation action of the ejector rod 1-12 into telescopic movement. The ejector rod hole and the first The spool hole 1-2 comm...

Embodiment 2

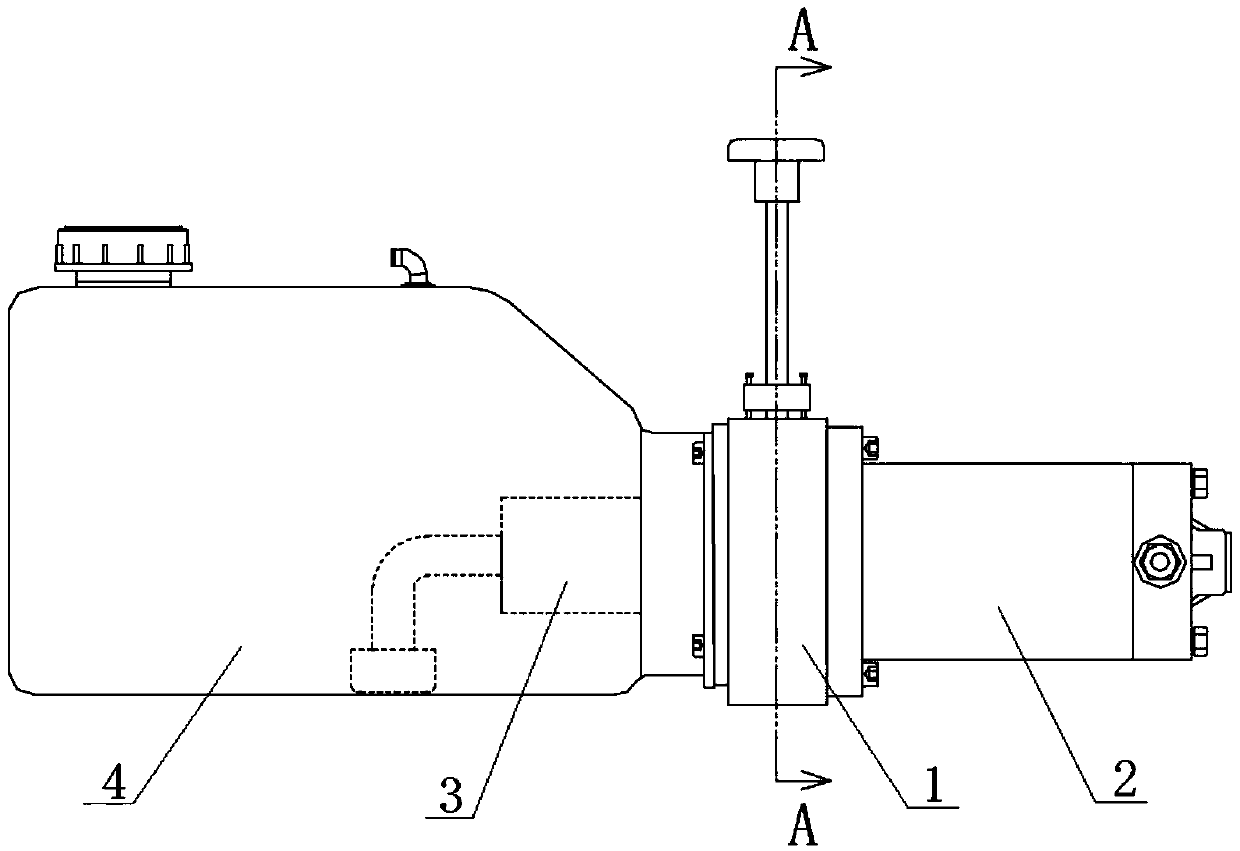

[0044] to combine figure 1 As shown, a hydraulic power unit of this embodiment includes a valve block 1, a motor 2, a gear pump 3 and an oil tank 4, and the valve block 1 adopts the valve block structure of the hydraulic power unit in Embodiment 1, and the valve block 1 is installed on Between the motor 2 and the gear pump 3, the output shaft of the motor 2 passes through the valve block 1 and is connected to the gear pump 3, the fuel tank 4 is connected to the gear pump 3, and the oil inlet holes 1-18 in the valve block 1 are connected to the gear pump 3 The oil inlet is connected, the oil return hole 1-14 and the oil drain hole 1-22 are connected with the oil tank 4, and the oil outlet hole is connected with the oil pipe joint 1-11 on the valve block 1 for connecting with the hydraulic equipment. A joystick 1-15 is provided on the valve block 1, and the ejector rod 1-12 is connected with the joystick 1-15; the joystick 1-15 has at least an oil supply flow adjustment control ...

Embodiment 3

[0047] This embodiment discloses a forklift using the hydraulic power unit described in Embodiment 2 above. The hydraulic power unit described in Example 2 is used in a forklift to replace the existing hydraulic power unit. According to practical use, the forklift lifts slowly at the beginning, and then the speed gradually increases, and the lift is stable and reliable. -15 can be controlled more flexibly, the forklift lifting action is smoother, and the operation is simpler and safer.

[0048] A hydraulic power unit valve block structure of the present invention and the hydraulic power unit and the forklift applied thereto control the linkage of the two groups of valve cores in the valve block through the rotating and telescopic movement of the ejector rod, and skillfully realize the gradual adjustment of the oil supply flow rate. The adjustment is simple and stable, and the oil return action can be controlled by the rotation of the ejector rod. There is no need to install va...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap