Intelligent industrial furnace and use method

An industrial furnace, intelligent technology, applied in furnaces, furnace components, furnace control devices, etc., can solve the problems of environmental pollution, waste gas without purification function, low degree of intelligent automation, etc., to protect the environment, reduce emissions, and ensure quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

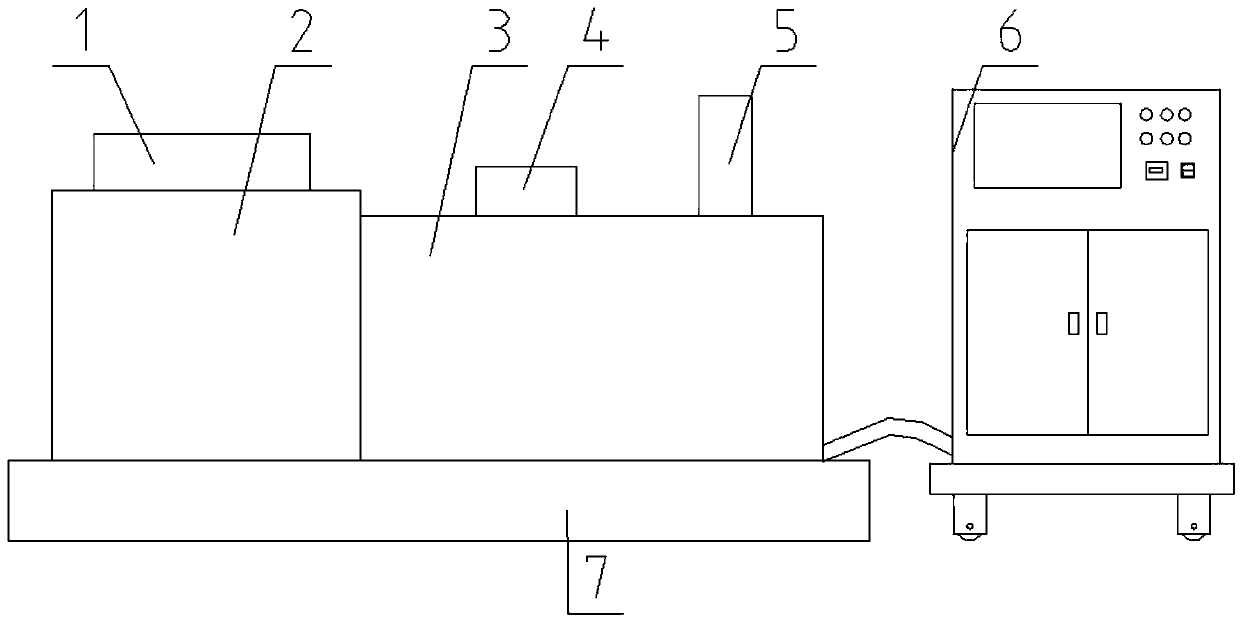

[0024] The present invention will be further described below in conjunction with accompanying drawing:

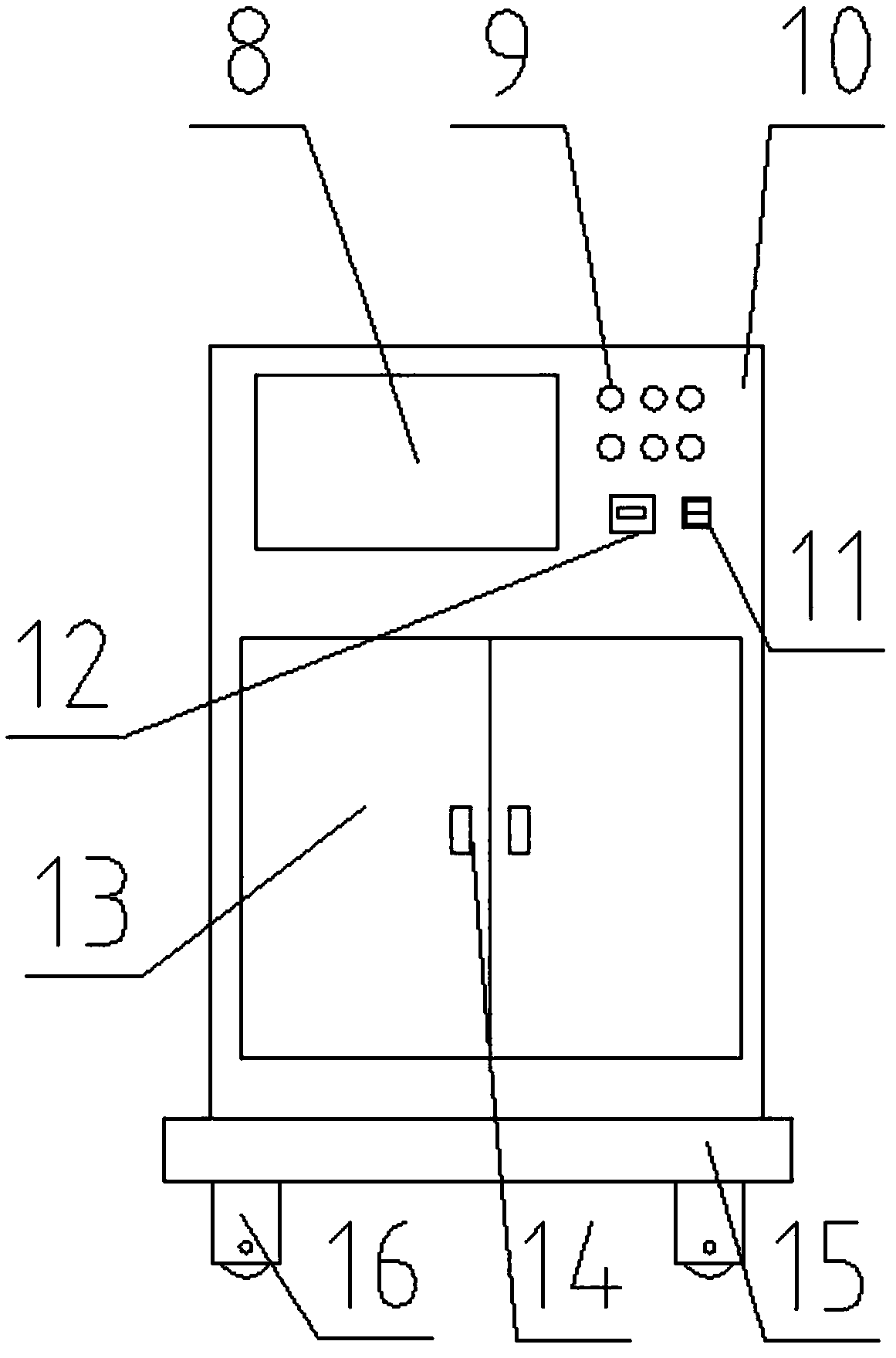

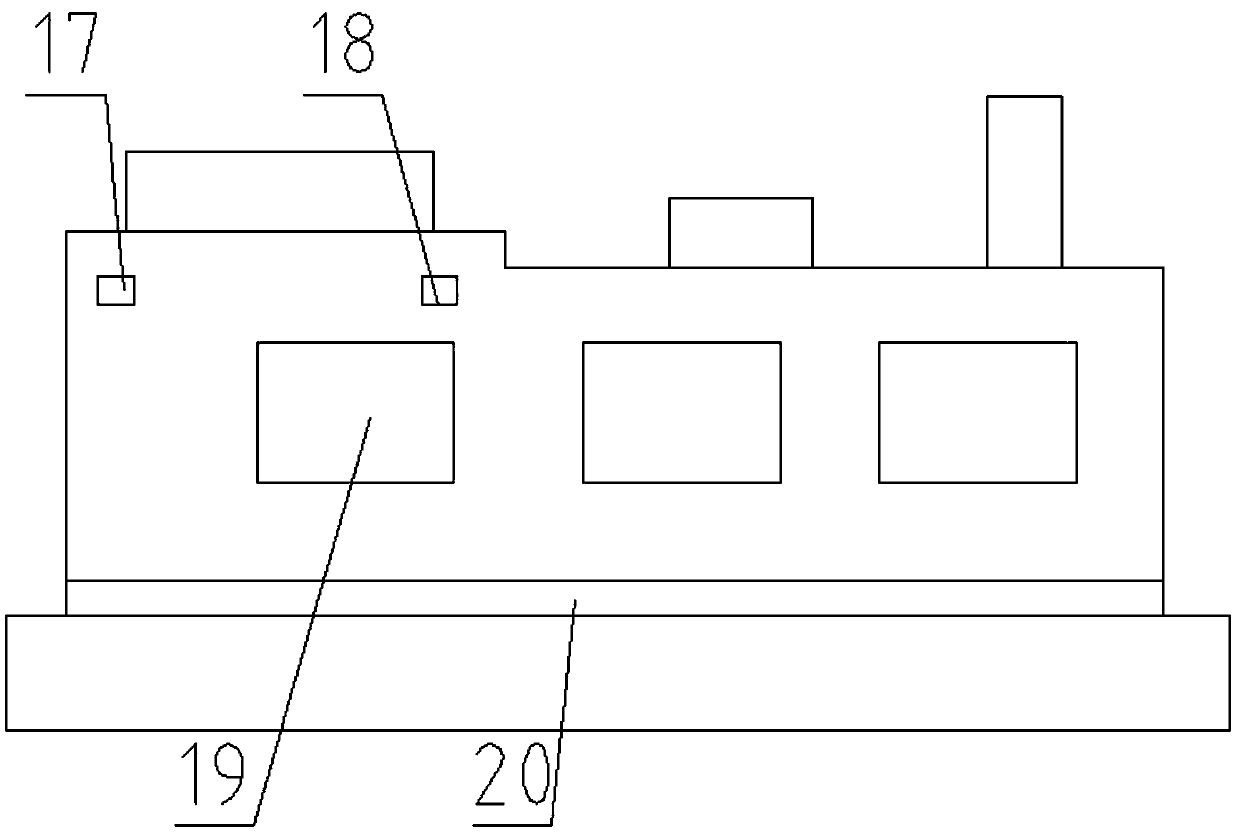

[0025] Such as Figure 1-Figure 4 As shown, an intelligent industrial furnace includes a feed inlet 1, a preheating furnace 2, and a heating furnace 3. The feed inlet 1 is arranged above the preheating furnace 2, and one side of the preheating furnace 2 is arranged There is the heating furnace 3, a voltage regulator 4 is arranged above the heating furnace 3, an exhaust pipe 5 is arranged on one side of the pressure regulator 4, and a gas detector 21 is arranged in the exhaust pipe 5, so A carbon fiber filter 22 is arranged below the gas detector 21, a gas reaction absorber 23 is arranged below the carbon fiber filter 22, an activated carbon absorption layer 24 is arranged below the gas reaction absorber 23, and an activated carbon absorption layer 24 is arranged below the activated carbon absorption layer 24. A preliminary filter 25 is provided, a pressure sensor 17 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com