Method and system for judging consistency of metering device based on pattern recognition

A technology of metering equipment and graphic recognition, which is applied in character and pattern recognition, calculation, energy-saving calculation, etc., can solve the problems of meter inconsistency, difficulty in obtaining evidence, unfavorable electricity stealing behavior, handling electricity bill recovery, etc., so as to improve work efficiency and reduce detection work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

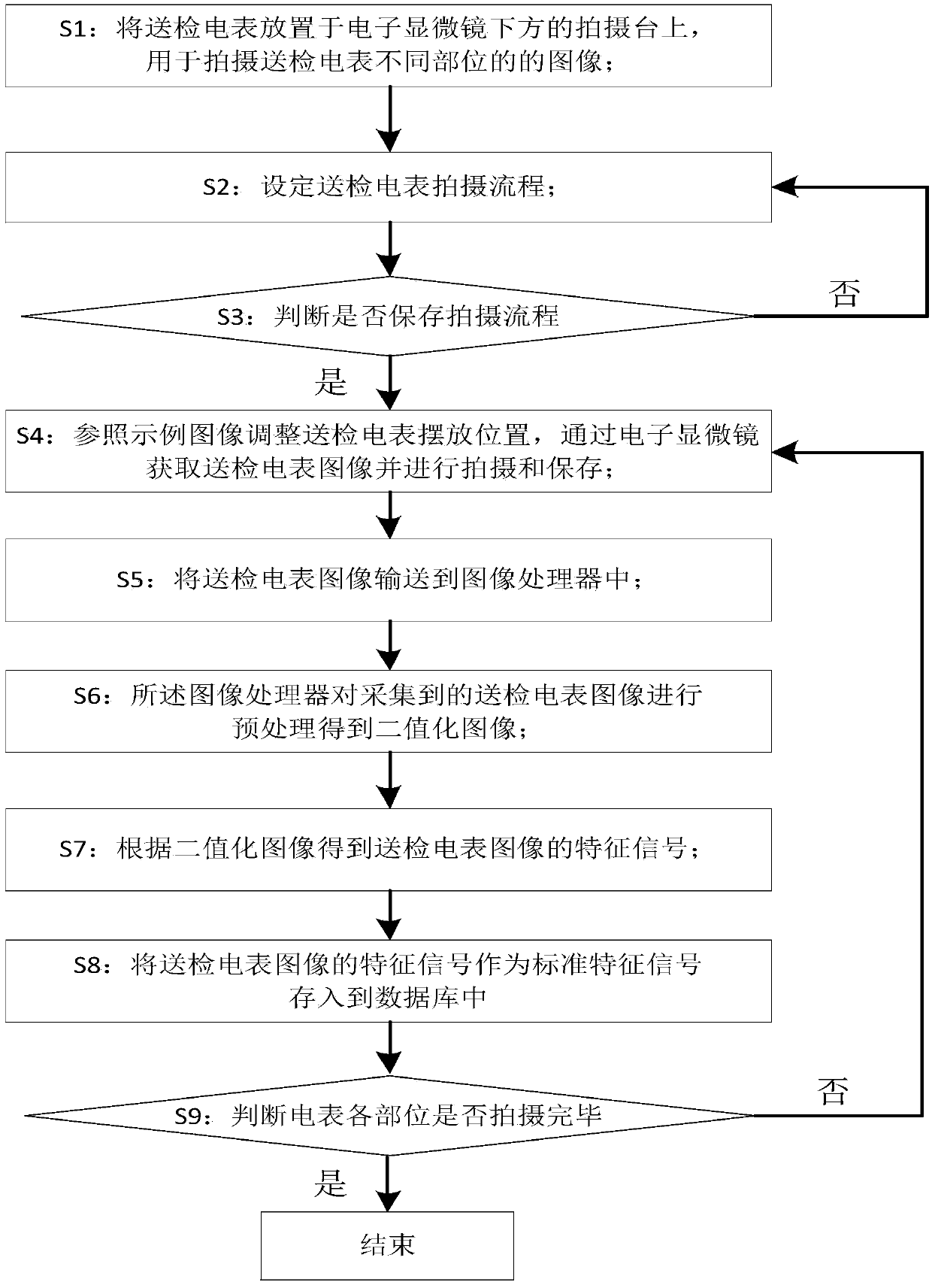

[0050] Example: such as Figure 1 to Figure 3 Shown; A method for judging the consistency of metering equipment based on graphic recognition, which includes:

[0051] S1: Collect images of different parts of the electricity meter submitted for inspection through an industrial microscope;

[0052] S2: Send the images of different parts of the electricity meter submitted for inspection to the judgment system for image processing; obtain the binarized image and the characteristic signals of the images of different parts of the electricity meter submitted for inspection and store them in the database as the batch of electricity meters submitted for inspection. Standard characteristic signal;

[0053] S3: Obtain the characteristic signals of images of different parts of the electricity meters delivered in the same batch as the electricity meters submitted for inspection or the on-site electricity meters;

[0054] S4: Compare the characteristic signal of the delivered electric met...

Embodiment 2

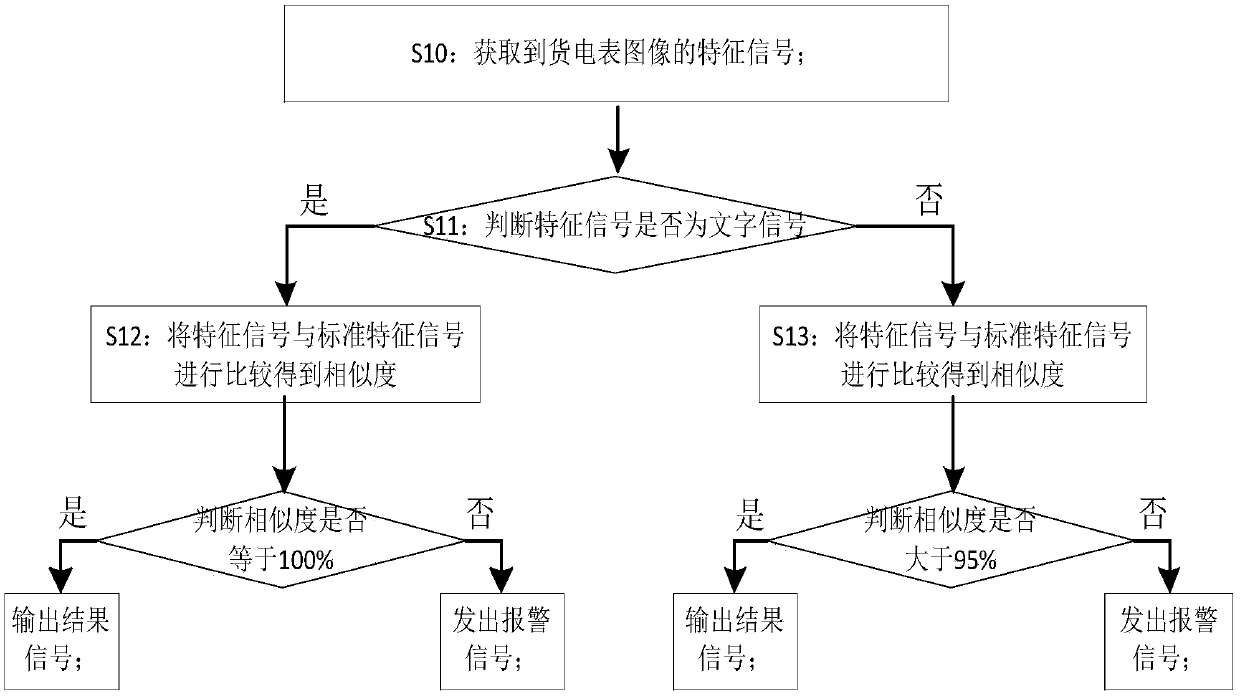

[0066] like figure 2 As shown, it is a flow chart of judging whether the electric meter of arrival is consistent with the electric meter sent for inspection for the present invention, including the following steps:

[0067] S10: After the same batch of electric meters from the same manufacturer arrives, it is necessary to perform sampling inspection on the arrived electric meters, and the method for obtaining the characteristic signal of the image of the electric meter arrived is as described in Embodiment 1;

[0068] S11: After obtaining the characteristic signal of the image of the electricity meter, it is necessary to determine whether the characteristic signal is a text signal;

[0069] S12: If the characteristic signal is a text signal, such as meter manufacturer, meter supply batch number, meter model, voltage, current, etc., then compare the characteristic signal with the standard characteristic signal to obtain the similarity, if the similarity is not 100 % will send...

Embodiment 3

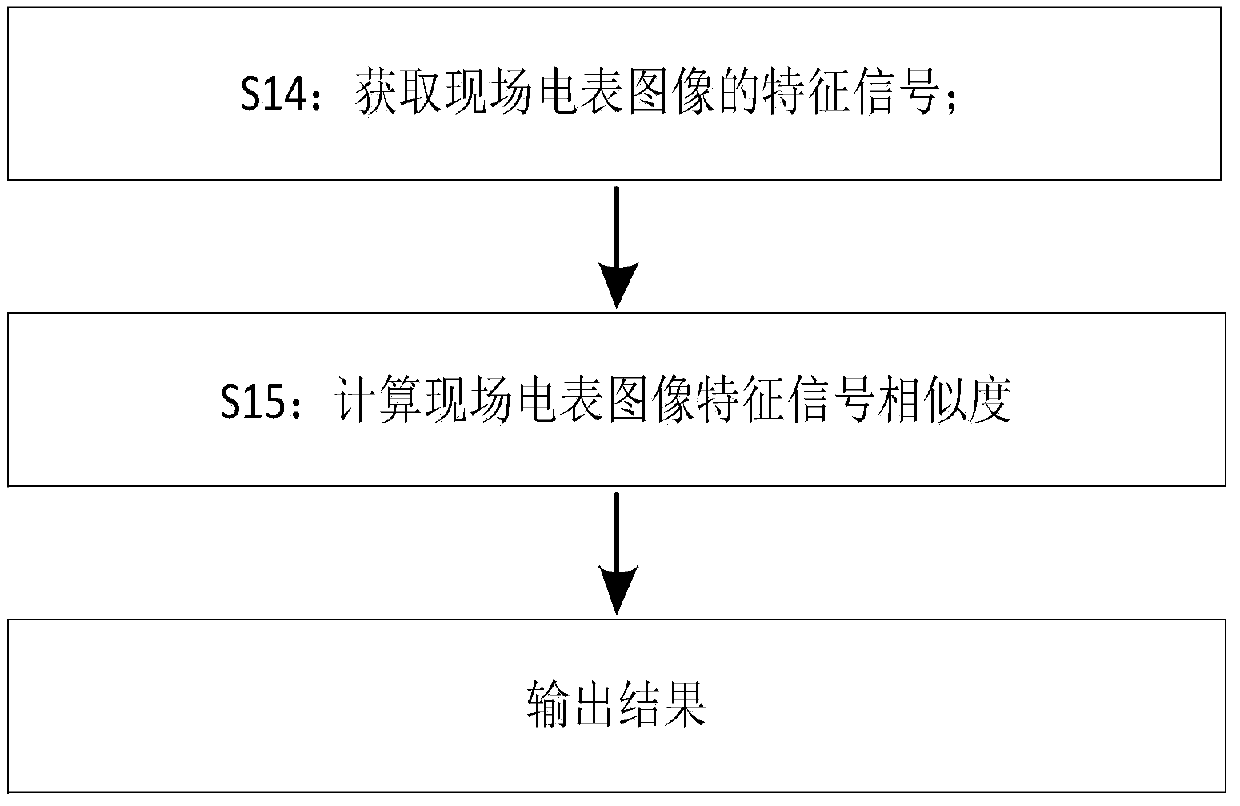

[0072] like image 3 As shown, it is a flow chart of judging whether the field meter of the present invention is consistent with the electric meter sent for inspection, including the following steps:

[0073] S10: Carry out sampling inspection on the same batch of on-site ammeters from the same manufacturer, and the method of obtaining the characteristic signal of the on-site ammeter image is as described in embodiment 1;

[0074] S11: Calculate the similarity of the image characteristic signal of the on-site electric meter, and then judge whether the on-site electric meter or the electric meter submitted for inspection is the same electric meter, the method is as described in embodiment 2;

[0075] A system for judging the consistency of metering equipment based on graphic recognition, which includes: an image acquisition device and an image processor;

[0076] The image acquisition device is used to obtain the images of different parts of the three types of electricity mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com