True triaxial fracturing simulation device of simulating proppant placement and working method thereof

A simulation device and proppant technology, applied in the field of true triaxial fracturing simulation device, can solve the problems of reducing the service life of fracturing pumps, easy wear of high-pressure pumps, easy-wear pumps, etc., and achieve enhanced bonding strength and improved sealing strength , the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

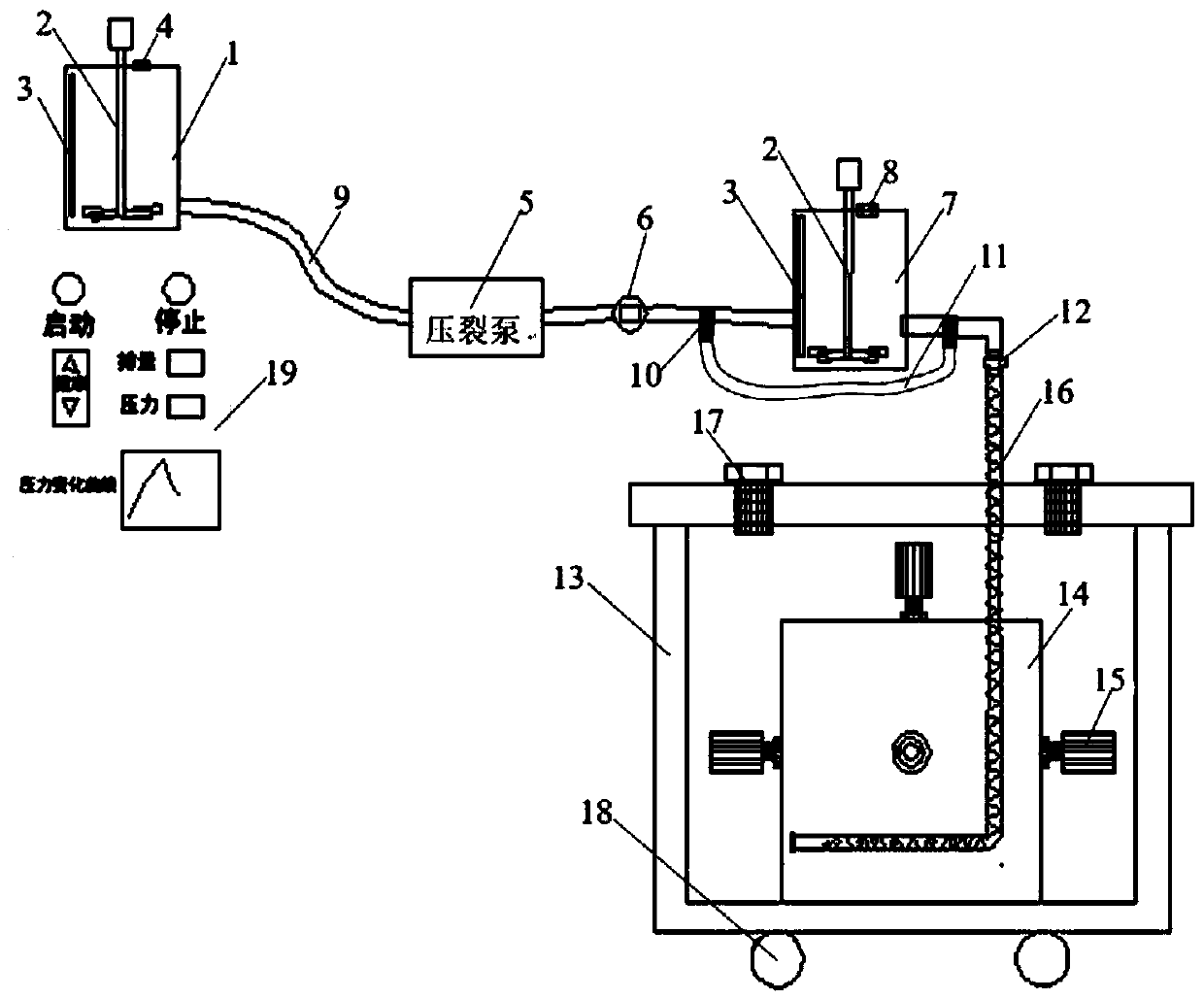

[0048] A true triaxial fracturing simulation device for simulating proppant placement in this embodiment, such as figure 1 As shown, through the main line 9, the fracturing fluid stirring tank 1, the fracturing pump 5, the proppant stirring tank 7, and the fracture growth simulation component are sequentially connected, wherein the proppant stirring tank is connected with branch pipelines in parallel, and the parallel interface is a turning point A switch 10; the top of the fracturing fluid mixing tank 1 is provided with a fracturing fluid inlet 4, and the bottom of the side is provided with a discharge port connected to the main line 9; the inside of the proppant mixing tank 7 includes a mixer 2, and the axial sides are respectively provided The fracturing fluid inlet and the sand mixing fluid outlet connected to the main pipeline, and the fracturing fluid inlet is located higher than the sand mixing fluid outlet, and the top has a proppant inlet 8; the fracture growth simulat...

Embodiment 2

[0061] The present embodiment is the working method of above-mentioned equipment, comprises steps as follows:

[0062] (1) Assemble the wellbore device 16, install the end sealing cover, determine the hole density, use nuts to seal the excess holes if necessary, and install the adapter 12 on the top of the wellbore;

[0063] (2) Prepare the raw materials required for making rock samples such as cement, concrete, coal rock, fiber, etc., consolidate together with the wellbore to make a reservoir simulation rock sample 14 of a certain size, and dry the rock samples to the state required for the experiment;

[0064] (3) Install the rock sample 14 and the wellbore 16 to the inside of the fracturing simulation container 13, and fix the jack 15 on the front, back, left, right, and upper 5 walls of the rock sample;

[0065] (4) Prepare the experimental fracturing fluid system and prepare proppant materials for fracturing;

[0066] (5) arrange the laboratory, move the experimental equ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com