Method for preparing perovskite film based on anti-solvent dynamic spin-coating

A perovskite and anti-solvent technology, applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve the problems of fine grains of perovskite thin films, and achieve the effect of flat and dense surface and reduced loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

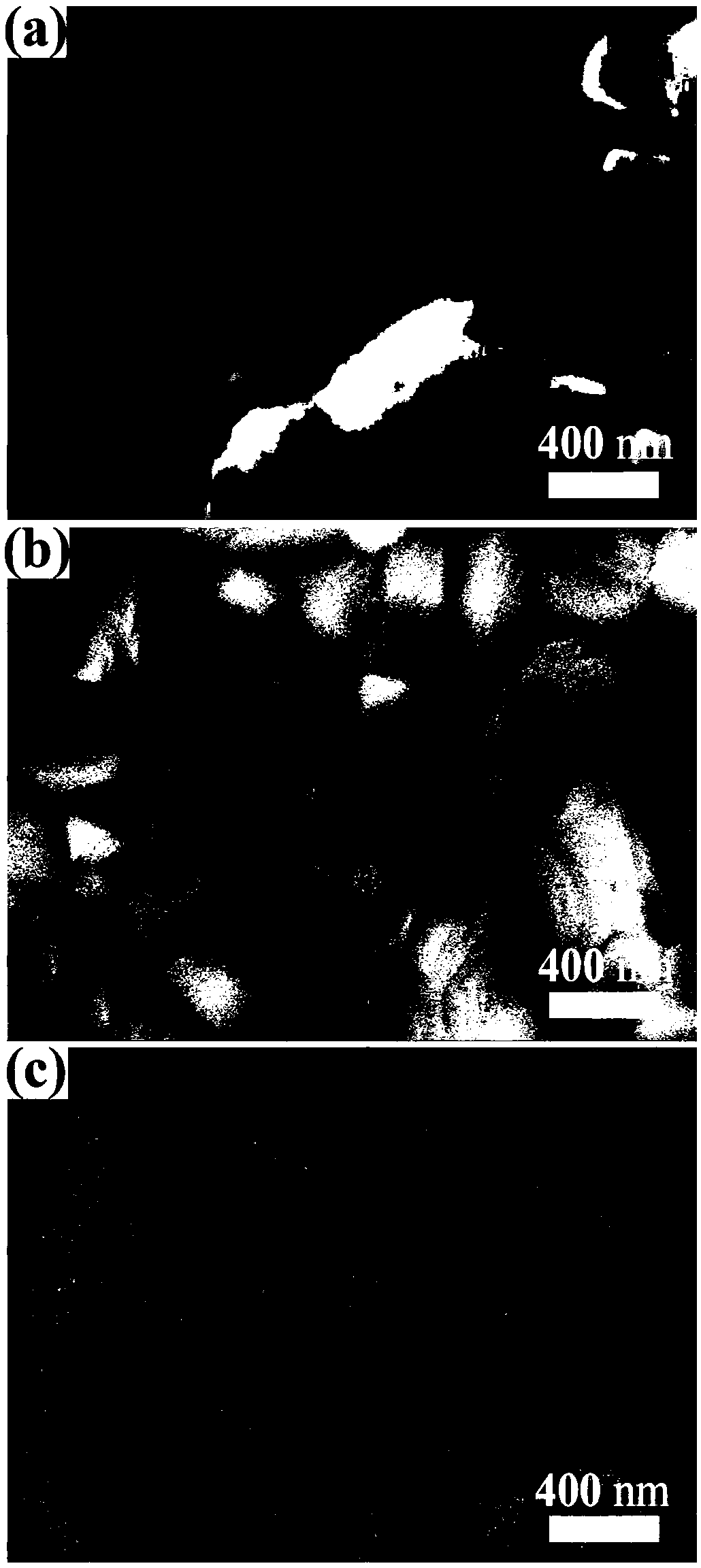

Embodiment 1

[0034] A method for preparing a perovskite film based on anti-solvent dynamic spin coating, specifically comprising the following steps:

[0035] Step 1. Clean the substrate:

[0036] 1.1 will bring TiO 2 The FTO conductive glass of the electron transport layer was ultrasonically cleaned in acetone, alcohol, and water for 20 minutes respectively, and dried in a vacuum drying oven;

[0037] 1.2 For the treated TiO in the previous step 2 The FTO conductive glass of the electron transport layer is subjected to 20min UV-ozone treatment to increase the hydrophilicity of the substrate;

[0038] Step 2, take lead iodide as solute, DMF as solvent, stir 12h, prepare the lead iodide solution that mass concentration is 0.416g / mL; 3 NH 31, MAI) as solute, isopropanol as solvent, stir 12h, preparation obtains the isopropanol solution that mass concentration is the iodomethylamine of 50mg / mL;

[0039] Step 3. Place the lead iodide solution prepared in step 2 on a heating and stirring t...

Embodiment 2

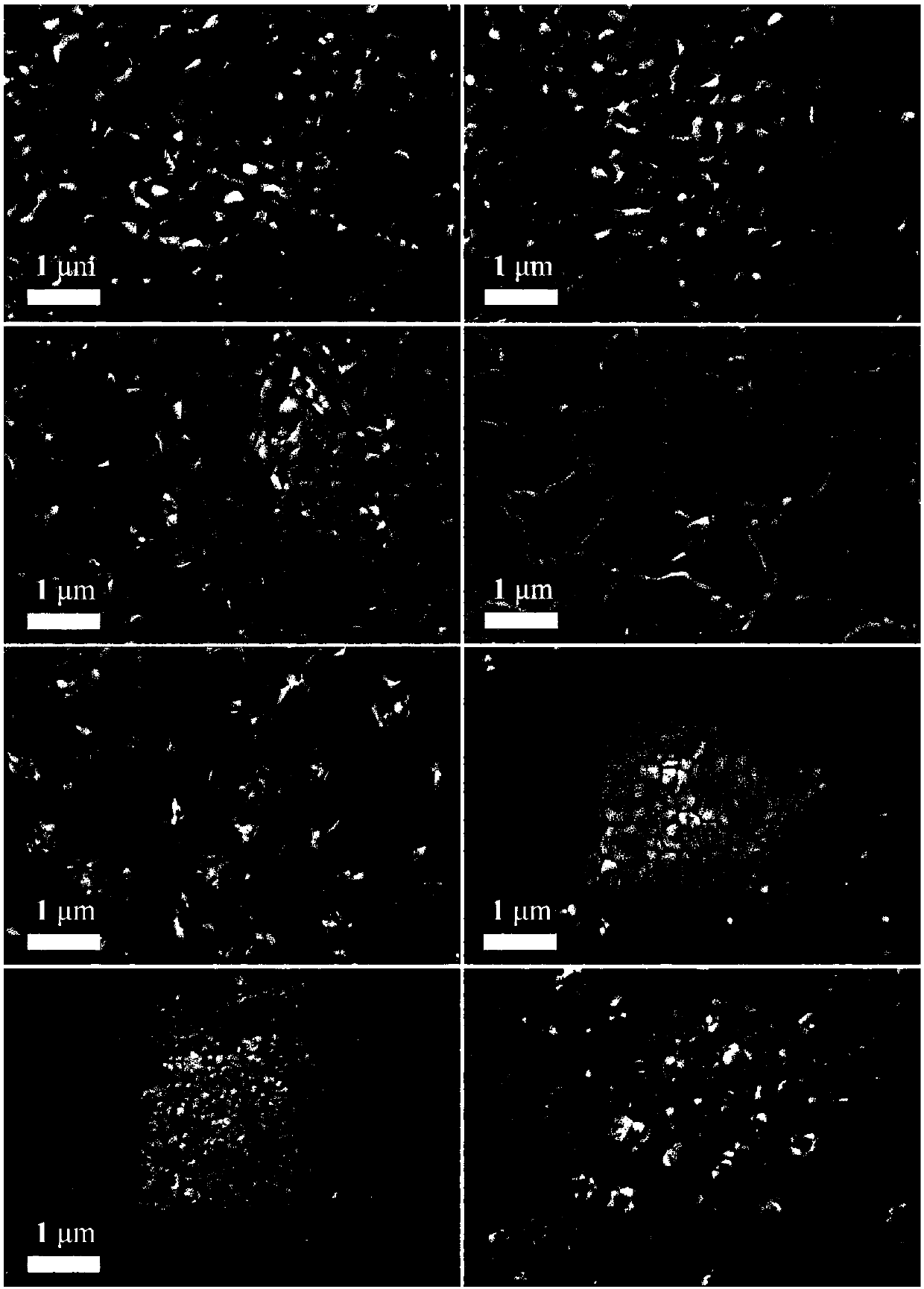

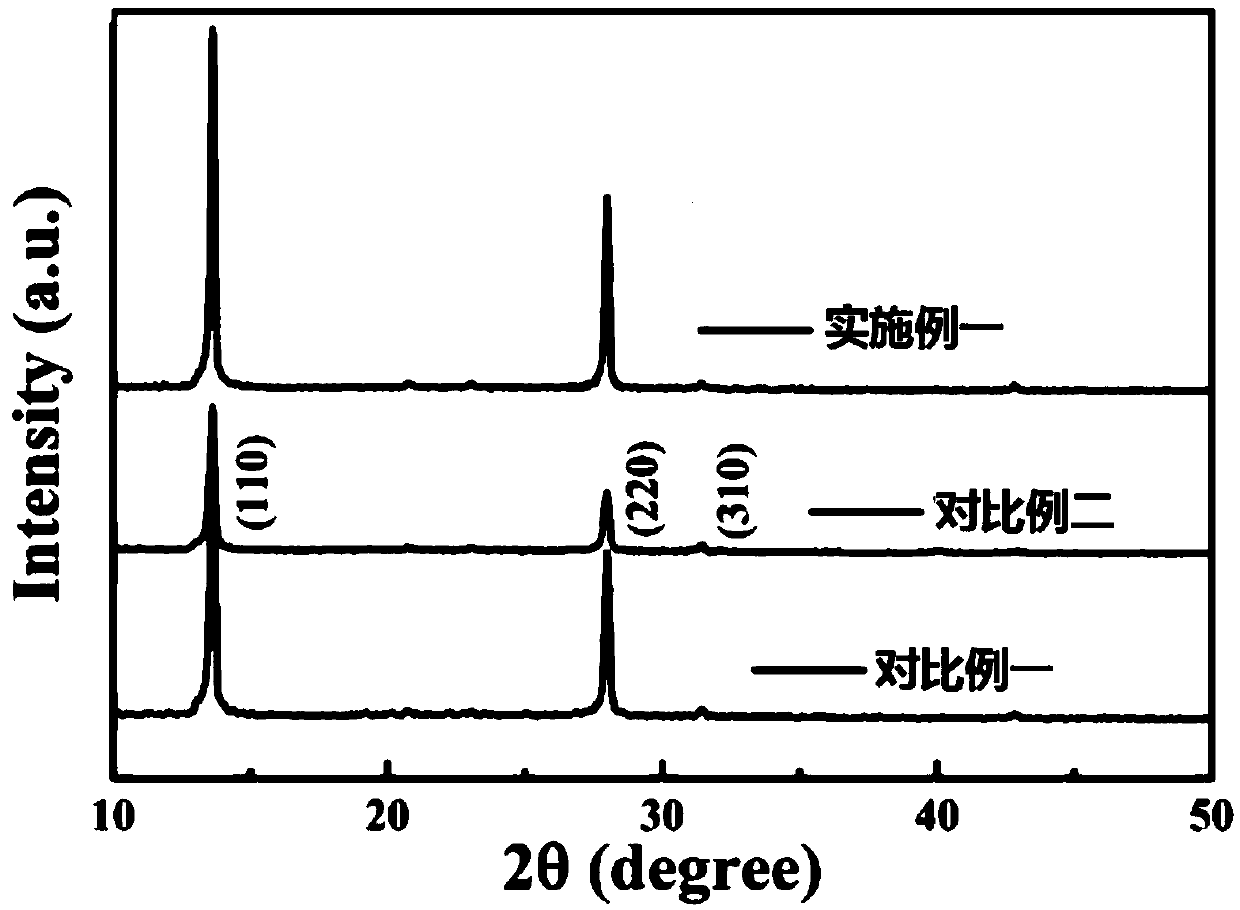

[0042] According to the steps of Example 1, the perovskite film was prepared, and the time of adding the isopropanol solution of MAI was set as: after spin coating 0s, 5s, 15s, 20s, 25s, and 30s, the isopropanol of methyl iodide was added dropwise solution. The SEM of the perovskite film that embodiment 2 obtains is as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com