Small self-propelled high-clearance spraying machine

A self-propelled, high-ground-gap technology, which is applied to the device for capturing or killing insects, applications, animal husbandry, etc., can solve the problem that spraying machinery is difficult to achieve control effects, crop planting row spacing is not uniform, and it is difficult to adapt to planting modes, etc. Problems, to achieve the effect of light weight, small volume, and reduce the compaction of the land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] specific implementation

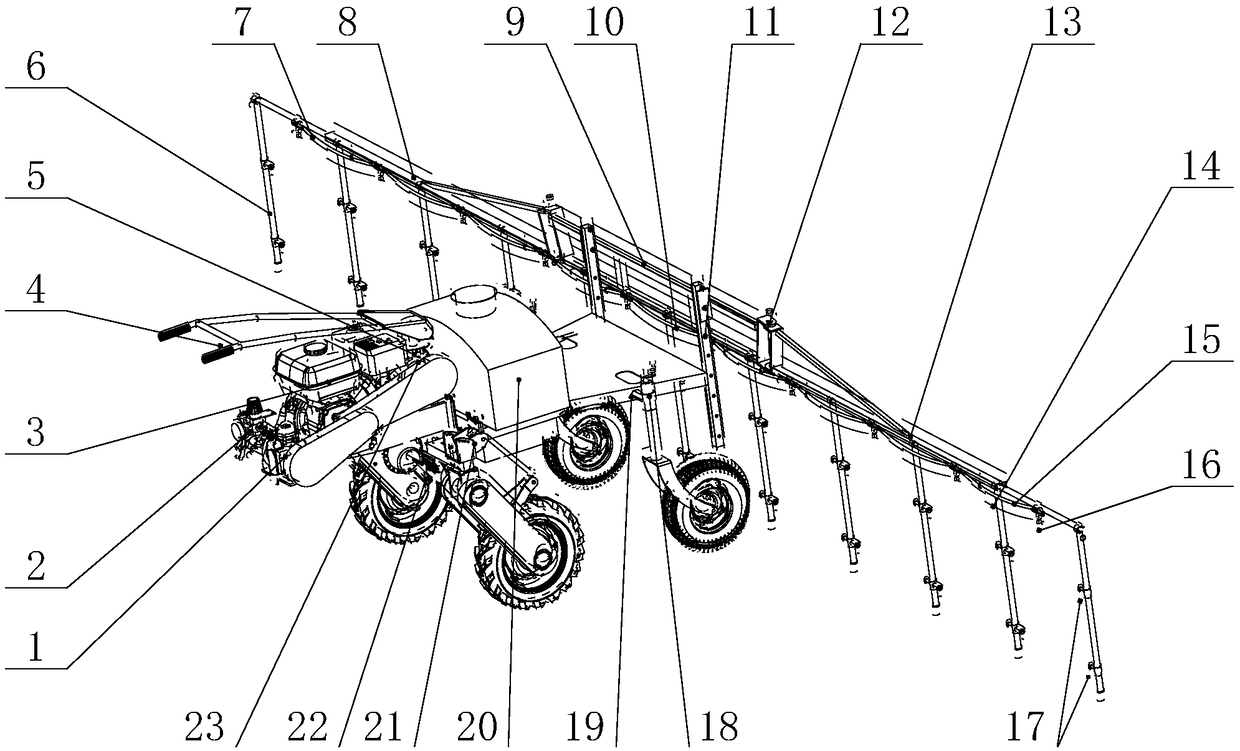

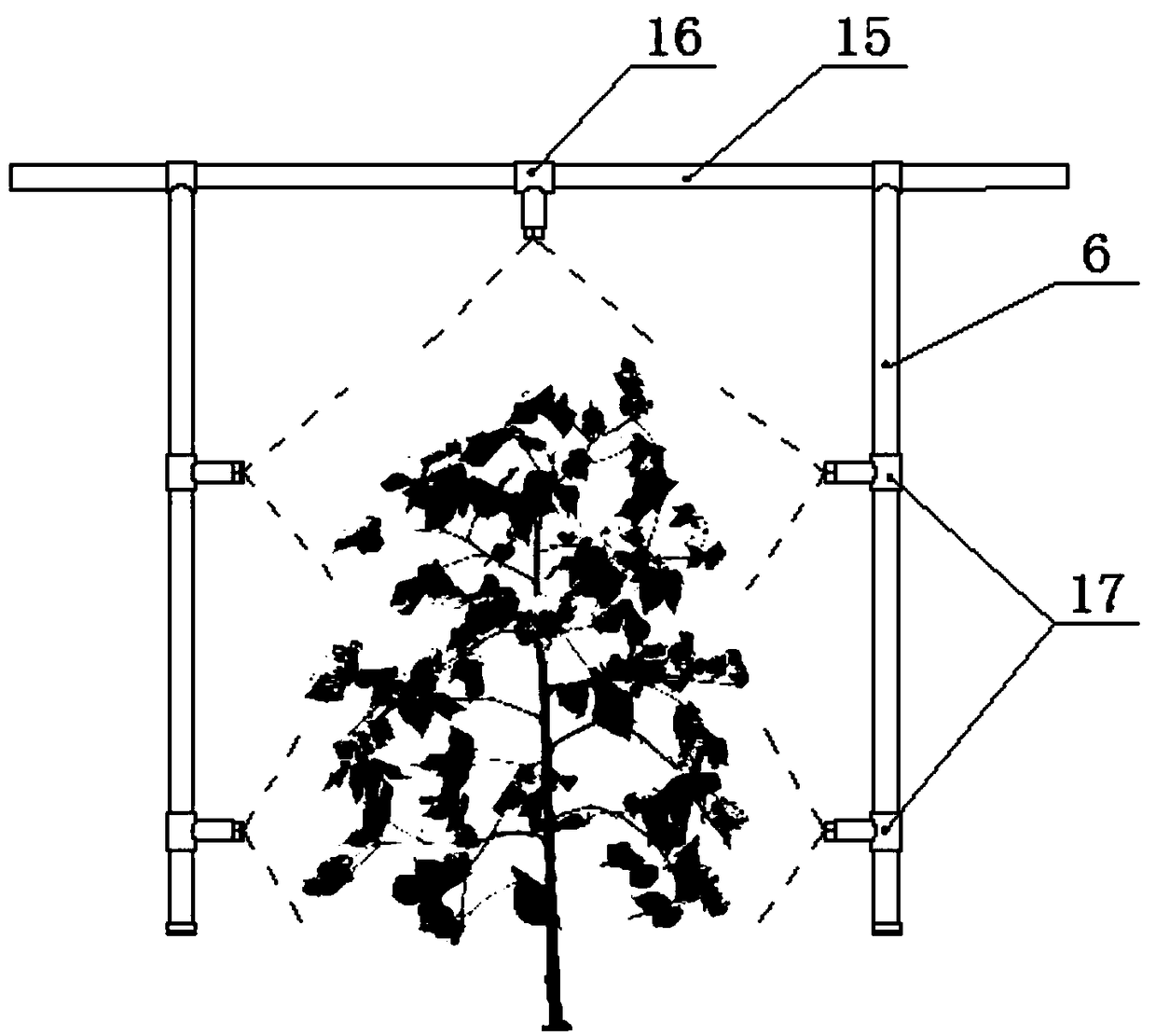

[0033] Such as figure 1 As shown, this embodiment takes the plant protection operation of ten rows of crops as an example, and can spray ten rows of crops at the same time.

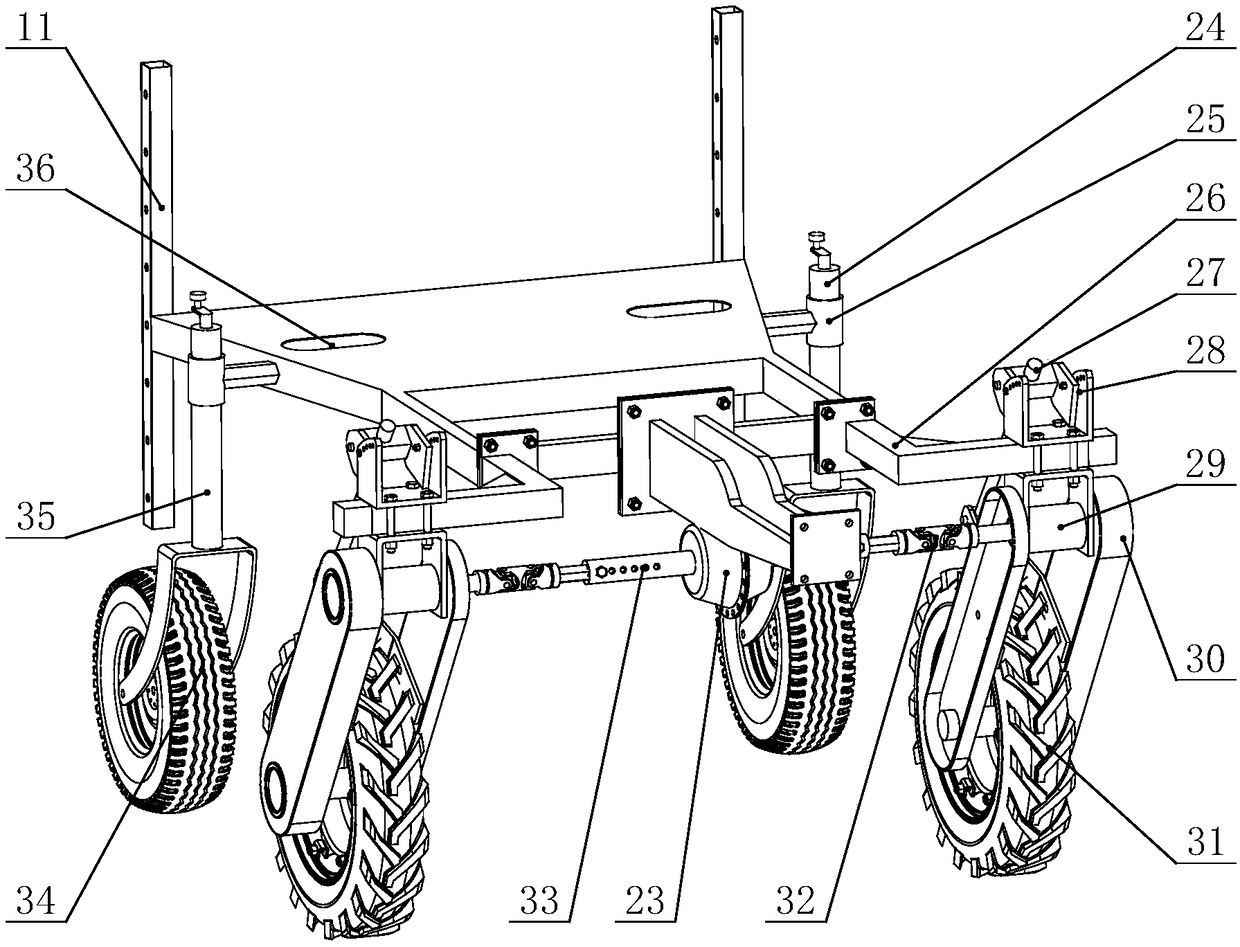

[0034] Before entering the field work, adjust the wheelbase of the sprayer according to the row spacing of crop planting. The wheelbase adjustment range is 1-1.6m. The fixing bolts are loosened so that the height adjustment seat 28 and the traveling wheel mounting seat can be slid left and right on the traveling wheel mounting frame 26 for adjustment, and then the fixed pin on the traveling wheel transmission shaft 33 is opened, and the traveling wheel transmission shaft 33 and the double cross The mounting shaft of the universal joint 32 is nested and connected, and the depth of embedding can be adjusted. One end of the mounting shaft is provided with a plurality of through holes to cooperate with the through holes of the transmission shaft 33, and the two are fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com