Multi-scale microstructure reactor

A microstructure reactor, multi-scale technology, applied in chemical/physical/physical chemical reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc., can solve the problem of long mixing time, complex structure, and reduced mass transfer Heat transfer rate and other issues, to achieve good mixing state, fast mass transfer rate, high mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

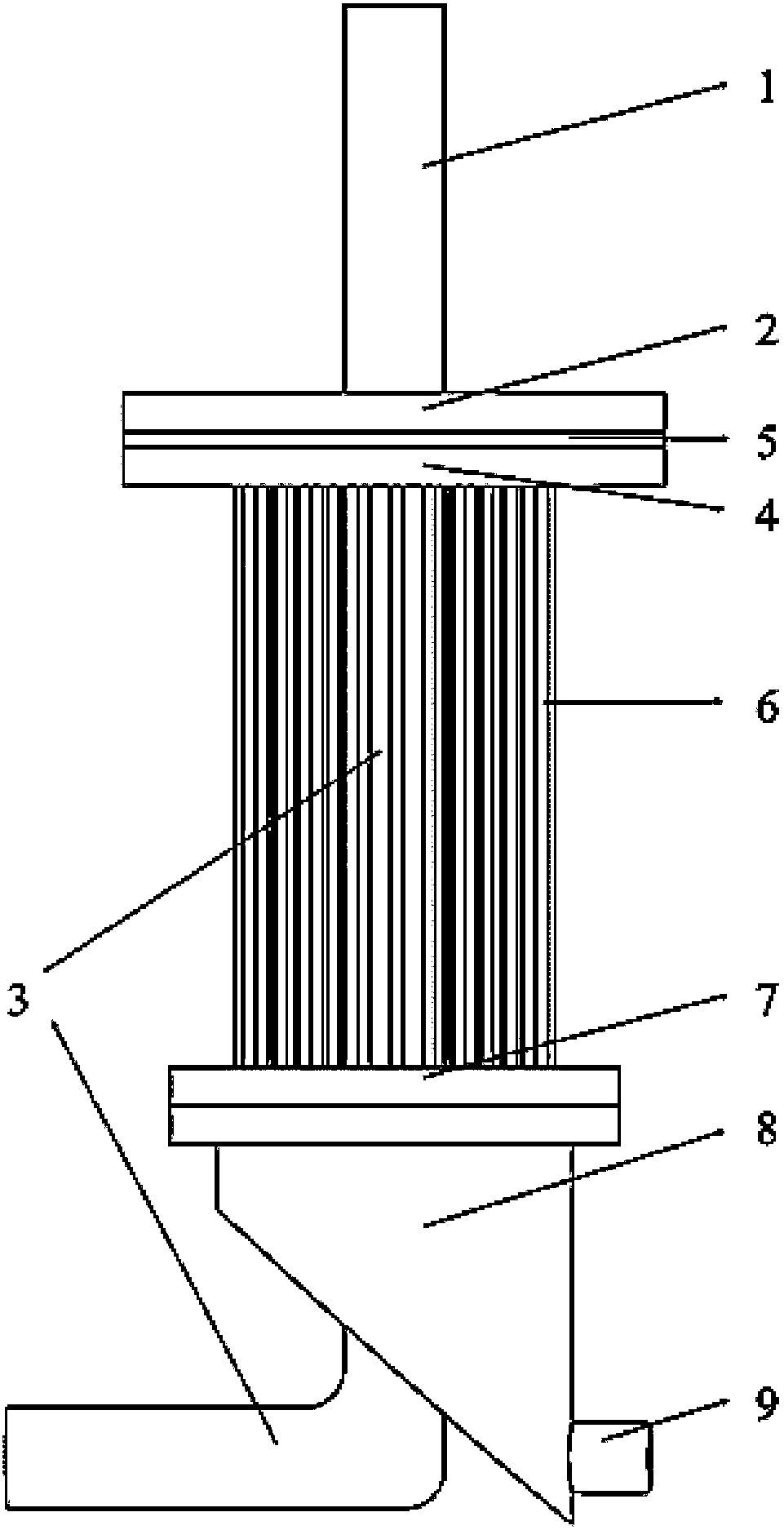

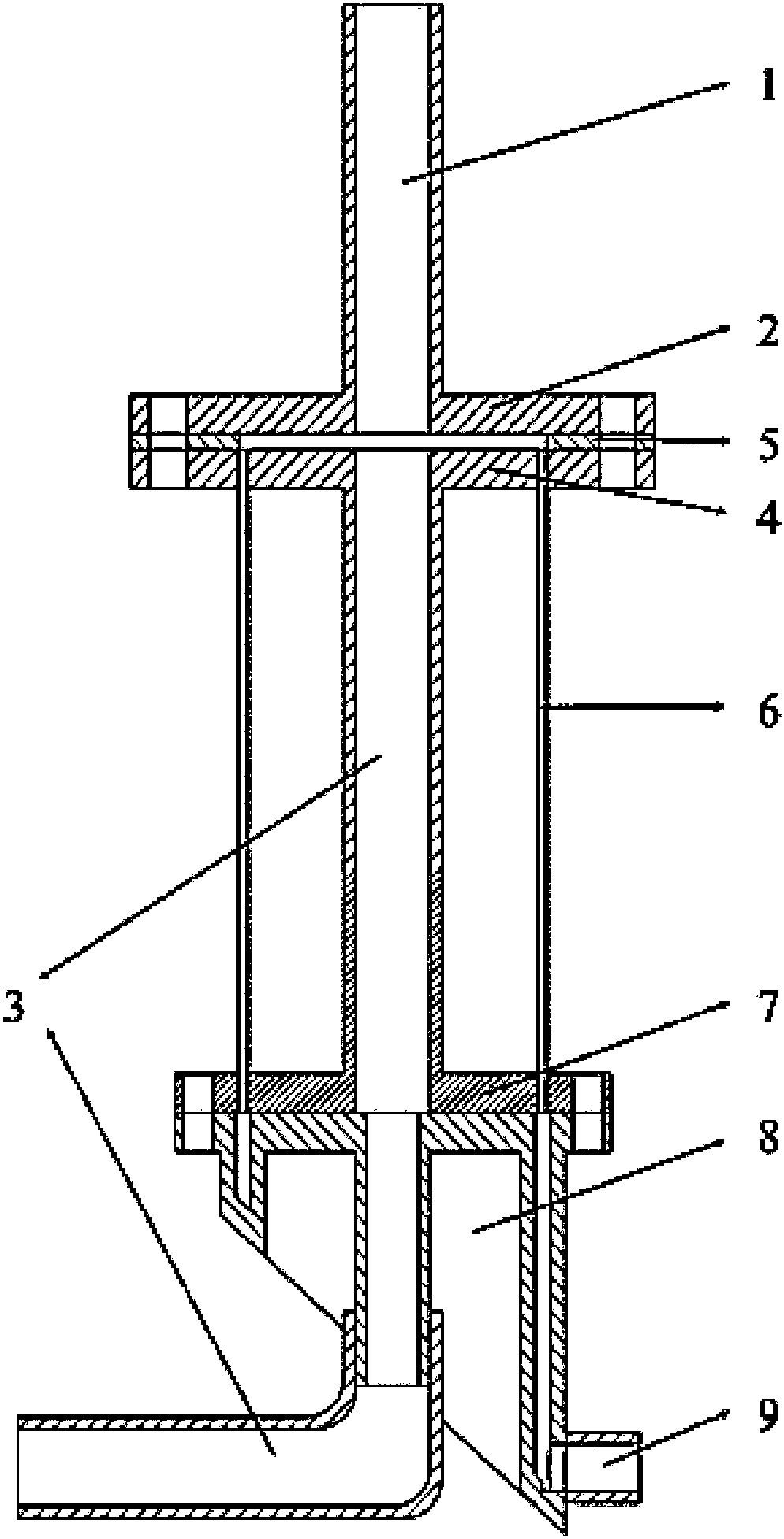

[0022] Such as figure 1 As shown, this embodiment includes: a lower fluid inlet pipe 3, a lower fluid inlet flange 4, an upper fluid inlet pipe 1, an upper fluid inlet flange 2, a mixing chamber 5, a capillary tube 6, and a collection chamber connected sequentially from top to bottom The cover plate 7, the collection chamber 8 and the outlet pipe 9, wherein: the upper fluid inlet pipe 1 and the lower fluid inlet pipe 3 are arranged coaxially, and pass through the upper fluid inlet flange 2 and the lower fluid inlet respectively from above and below the mixing chamber 5 The flange 4 communicates with the mixing chamber 5; the capillary 6 is arranged radially around the lower fluid inlet pipe 3 in a single-layer or multi-layer annular array, and clings to the inner wall of the mixing chamber 5.

[0023] The mixing chamber 5 is an annular thin flange.

[0024] The thickness of the mixing chamber 5 is 0.5-5mm, and the inner diameter is 10-500mm.

[0025] The mixing chamber 5 can...

Embodiment 2

[0042] The diameter of the upper fluid inlet pipe 1 and the lower fluid inlet pipe 3 are both 3mm, the thickness of the mixing chamber 5 is 1mm, and there are 630 capillaries with an inner diameter of 0.75mm and a length of 0.1m.

[0043] In this example, chemical probe technology was used to characterize the mixing performance of the reaction system.

[0044] Described reaction system is: H 2 BO 3 - +H + →H 3 BO 3 , 5I - +IO 3 - +6H + →3I 2 +3H 2 O;

[0045] The generated iodine will be further combined with I - Reaction I 3 - :

[0046] Detection of I by UV absorption spectroscopy 3 - concentration, and then calculate the separation index: where: X s is the separator index, C i is the concentration of component i substance, unit mol / L; V is the concentration of H 2 BO 3 - , I - and IO 3 - The volume flow rate of the solution, in mL / min; n i is the amount of component i substance, unit mol; subscript O indicates the value in the initial state.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com