Forming mold for manufacturing elliptic double-film greenhouse framework

A molding die and ellipse technology, applied in the direction of metal extrusion die, etc., can solve the problem of not being able to cover the inner and outer two layers of shed film, and achieve the effect of strong bearing capacity, increasing indoor temperature and high accumulated temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

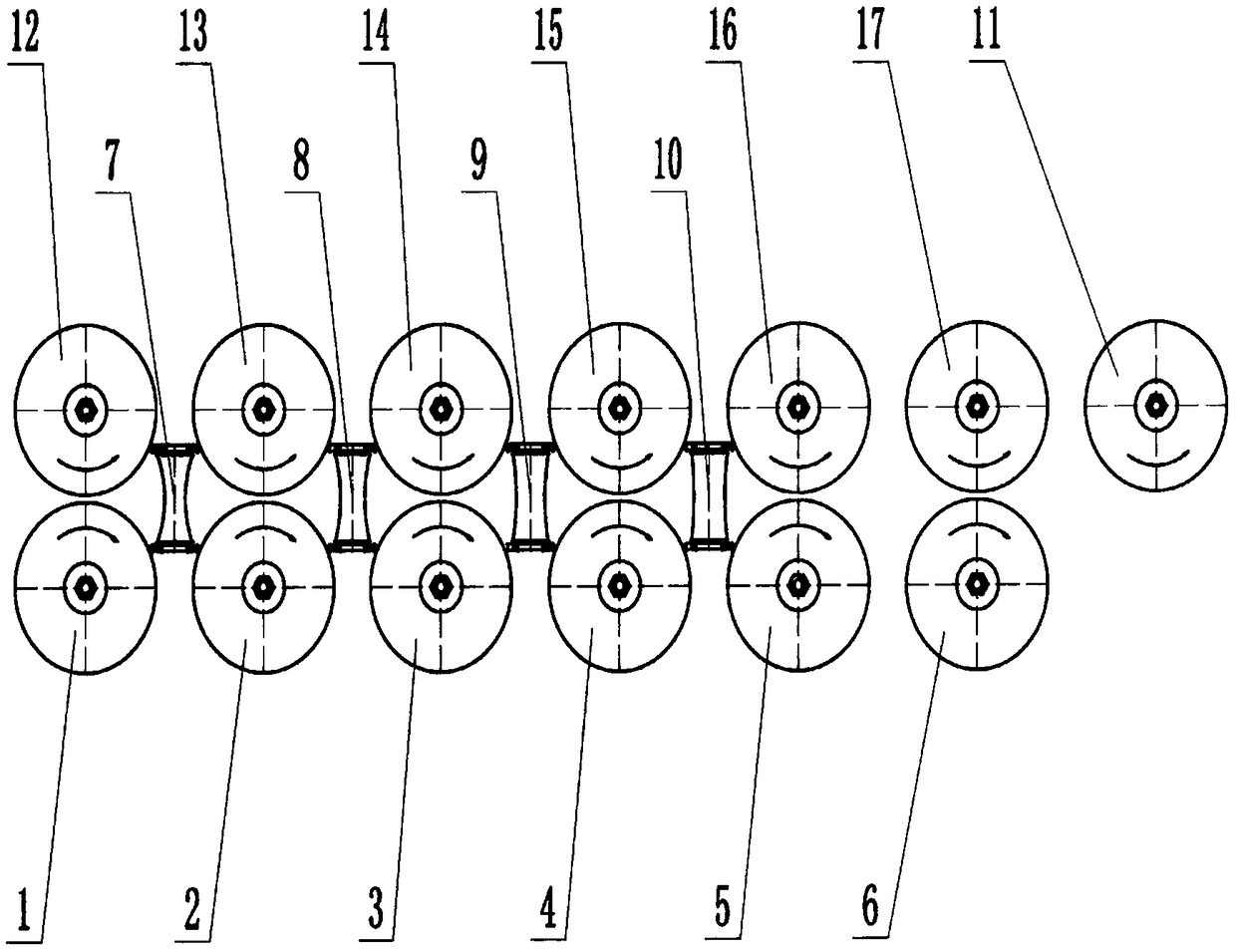

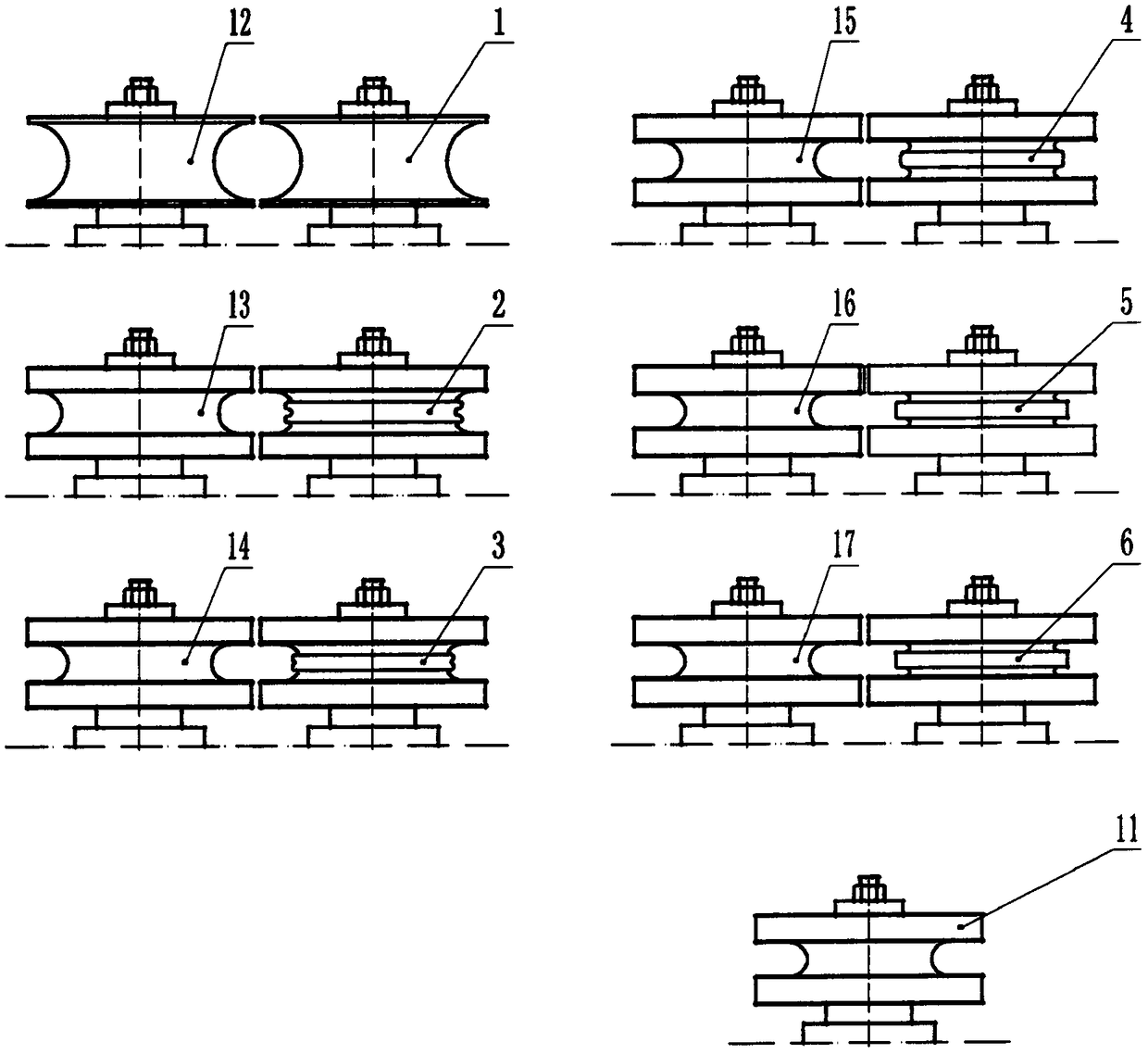

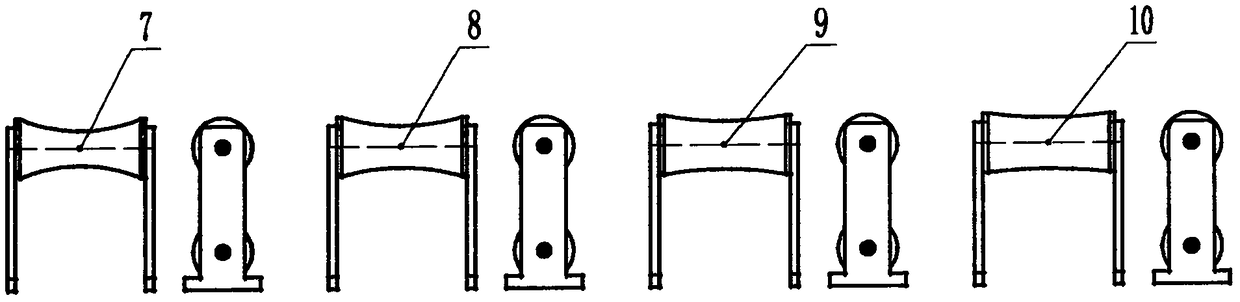

[0011] Such as figure 1 Shown, a kind of forming mold of manufacturing elliptical double-coated greenhouse framework, comprises the first ellipse forming die wheel 12, the second ellipse forming die wheel 13, the 3rd ellipse forming die wheel 14, the 4th ellipse forming die wheel 15, The fifth ellipse forming die wheel 16, the sixth ellipse forming die wheel 17, the first flattening die wheel 7, the second flattening die wheel 8, the third flattening die wheel 9, the fourth flattening die wheel 10, driving die Wheel 11, first groove forming die wheel 1, second groove forming die wheel 2, third groove forming die wheel 3, fourth groove forming die wheel 4, fifth groove forming die wheel 5, sixth Groove forming die wheel 6, the first flattening die wheel 7 is installed on the first ellipse forming die wheel 12, the first groove forming die wheel 1 and the second ellipse form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com