Preparation method and system for man-made stone slab

An artificial stone slab and preparation system technology, applied in the field of building materials, can solve the problems of high preparation cost, high power consumption, high formwork cost, etc., and achieve the effect of improving hardening effect, reducing floor space, and quick demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Now take the preparation of organic quartz slabs as an example, including the following steps:

[0031] (1) Weigh the raw material of quartz slate, mix the components uniformly, spread the uniformly mixed material on the forming template, then send the forming template into the vacuum chamber, vacuumize, vibrate and pressurize, and obtain the soft quartz slate billet.

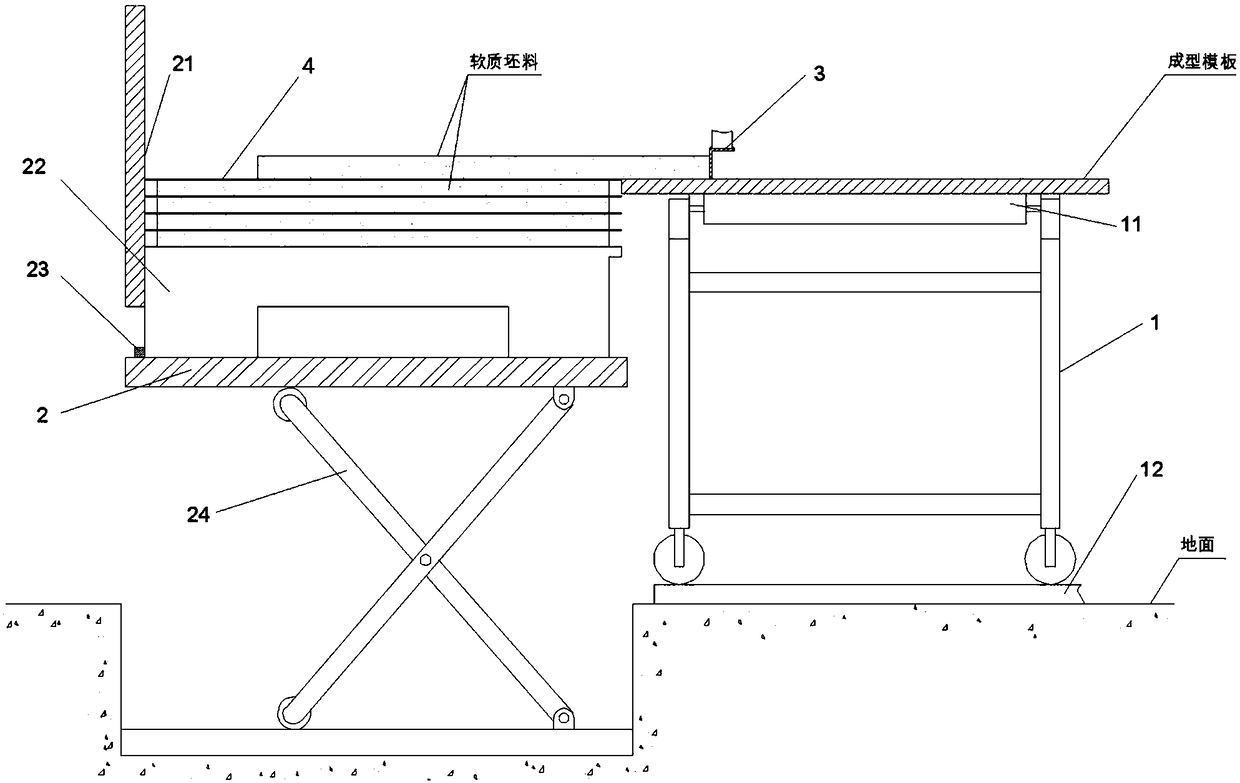

[0032] (2) Lifting platform 2 is placed in a pit below the ground level, a stand 22 is installed on the lifting platform 2, a thin template 4 is set on the stand 22, and the forming template is sent to the On the moving roller table 1, adjust the height of the lifting platform 2 (electric or hydraulic), so that the upper surface of the thin formwork 4 (in this embodiment, a PVC plate with a thickness of 3 mm) on the lifting platform 2 is flush with the upper surface of the forming formwork The upper surface of the flat or thin template 4 is slightly lower than the upper surface of the forming template b...

Embodiment 2

[0043] The difference between this embodiment and Example 1 is that the prepared quartz slab is an inorganic quartz slab. Correspondingly, the steps after step 7 of the above-mentioned Example 1 are:

[0044] (8b) After 24 hours at normal temperature, the soft blank has solidified into a hard blank. At this time, the strength of the plate can reach more than 30% of the strength of the 28-day age; use a mobile suction cup machine to separate the thin template 4 from the hard blank , and put them on different stands. In this process, the plastic film covering the hard blank should be uncovered first, and then the hard blank should be placed on another stand with a mobile suction cup machine, and the hard blank should be given Water it, let it soak, and then cover with the plastic film that was removed earlier.

[0045] (9b) Put the hard billet frame separated from the thin formwork into the designated position, after 6 days at normal temperature, its strength can reach more than...

Embodiment 3

[0049] Such as figure 1 As shown, the present invention also provides an artificial stone slab preparation system, the artificial stone slab preparation system includes a vacuum vibration pressurized chamber connected in sequence, a moving roller table 1 and a lifting platform 2, and the moving roller table 1 is connected with a transfer device , the soft quartz slab blank prepared in the vacuum vibration pressurization chamber is transported to the mobile roller table 1, and the transfer device pushes the soft artificial stone slab blank from the mobile roller table 1 to the lifting platform 2.

[0050] As a preferred embodiment, the moving roller table 1 is equipped with a moving roller table roller 11, and the forming template loaded with the soft artificial stone slab is transferred to the moving roller table 1 through the moving roller table roller 11.

[0051] As a preferred embodiment, the moving roller table 1 travels on the moving roller table track 12 and is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com