Graphite nano-sheet printing ink, and preparation method and use of antenna printed by using printing ink

A technology of graphite nanosheets and printing ink, which is applied in the field of antenna materials, can solve the problems of low conductivity and resistance to bending of printed antennas, and achieve a balance between preparation cost and conductivity, balance between preparation cost and product performance contradictory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Composition of graphite nanosheet printing ink:

[0035]

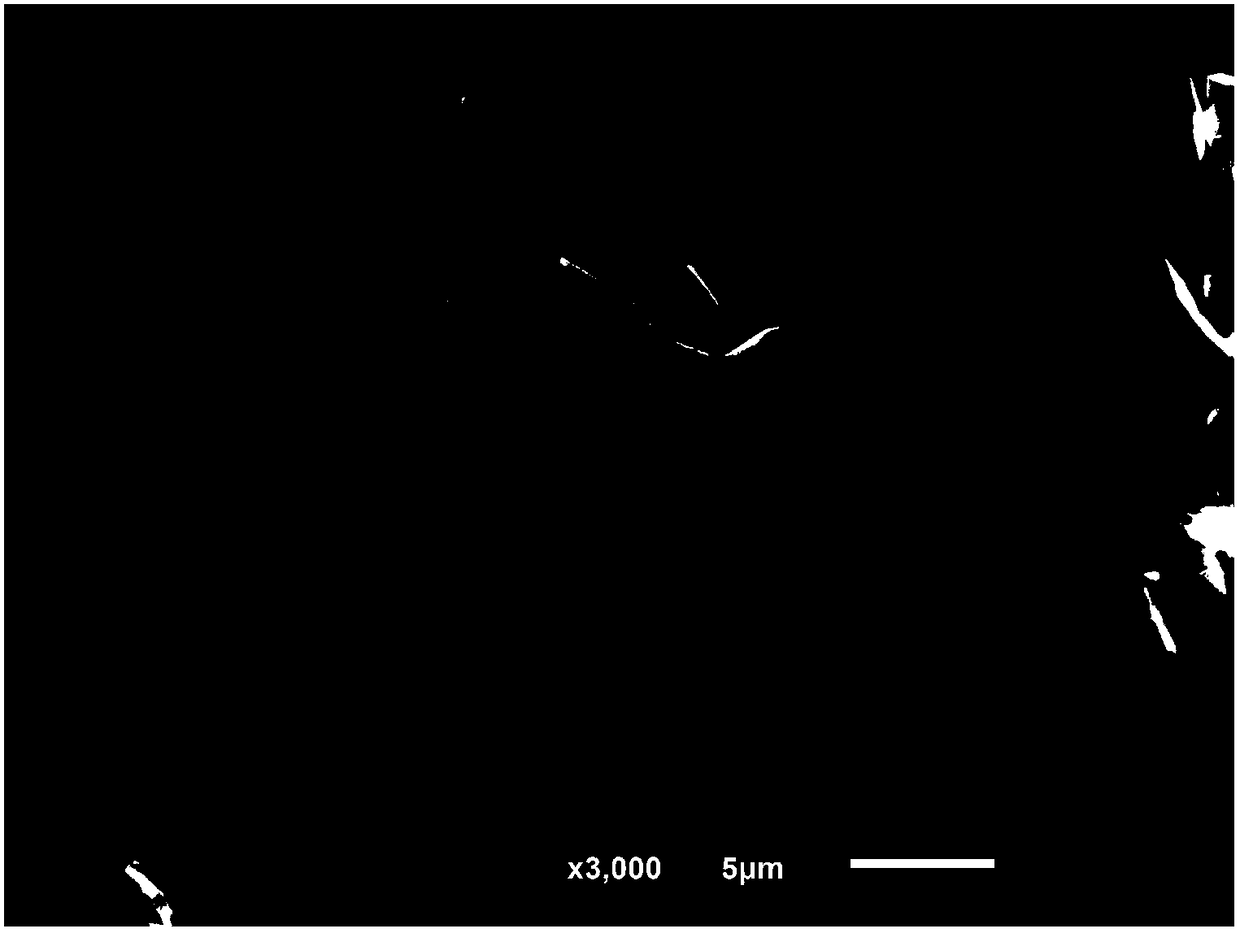

[0036] Graphite nanosheets are prepared using the jet cavitation equipment disclosed in Chinese invention patent CN201110190763.3: use graphite and solvent (ethanol-water mixed solution, wherein the volume fraction of ethanol is 50%) to prepare a graphite mixed solution with a concentration of 10mg / ml, The graphite mixture was treated at a pressure of 30 MPa for 0.5 hour and then directly dried to obtain graphite nanosheets. The average thickness of the prepared graphite nanosheets is about 10nm, the maximum thickness is about 23nm, the proportion of sheets with a thickness less than 3.4nm is less than 8%, the average lateral size is about 8 microns, and the largest lateral size is about 11 microns.

[0037] Stir the various raw materials of the ink with a magnetic stirrer at a speed of 1000 rpm for 1 hour to mix them evenly to obtain graphite nanosheet printing ink; print the graphite nanosheet printing ink ...

Embodiment 2

[0040] Composition of graphite nanosheet printing ink:

[0041]

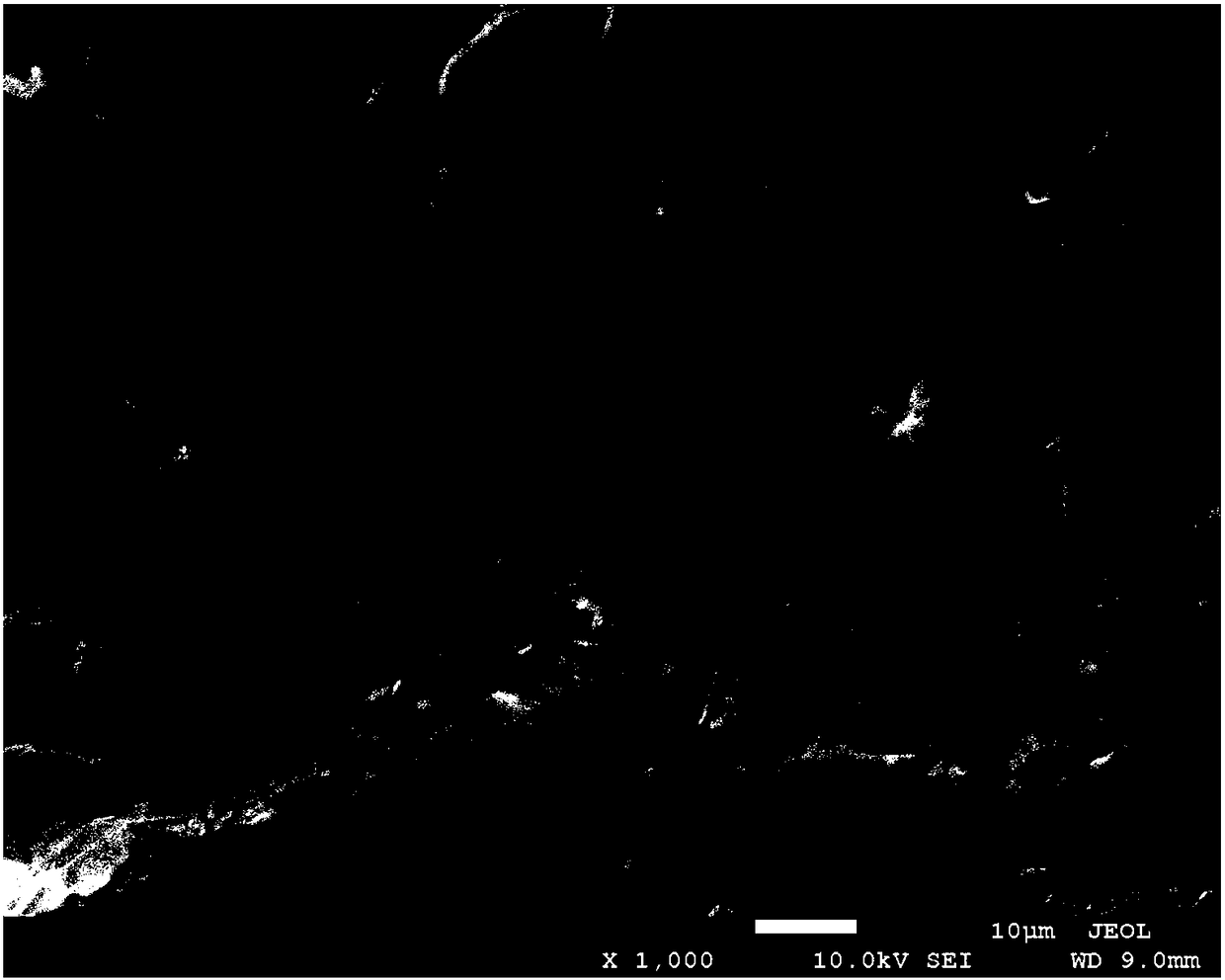

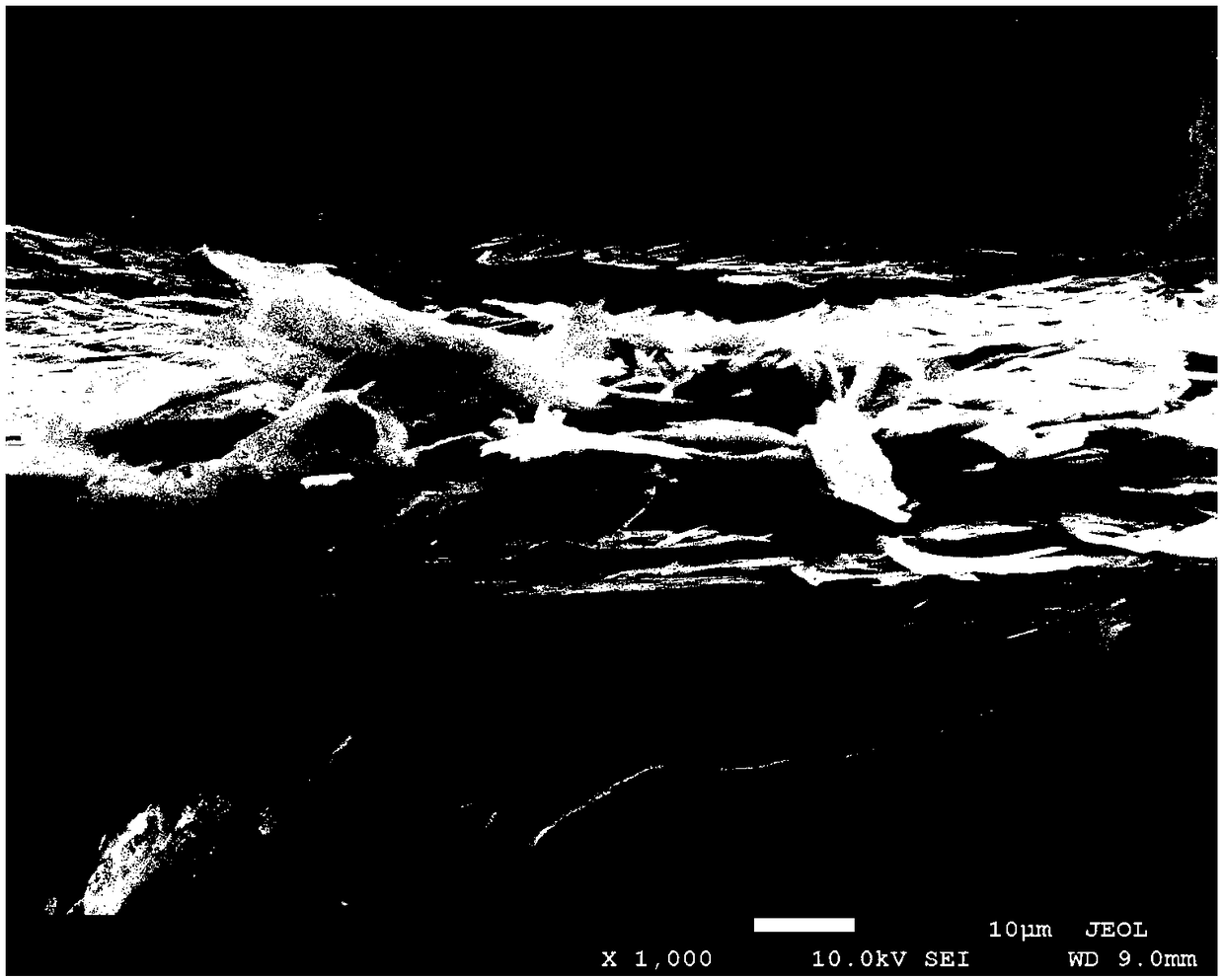

[0042] Graphite nanoplate adopts high-shear method to prepare: with graphite and solvent (isopropanol-water mixed solution, wherein the volume fraction of isopropanol is 60%) preparation concentration is the graphite dispersion liquid of 20mg / ml, the graphite dispersion liquid adopts A high-speed homogenizer was processed at a speed of 9500 rpm for 3 hours and then suction-filtered to obtain graphite nanosheets. The average thickness of the prepared graphite nanosheets is about 30nm, the maximum thickness is about 70nm, the proportion of sheets with a thickness less than 3.4nm is less than 6%, the average lateral size is about 10 microns, and the largest lateral size is about 40 microns.

[0043] The various raw materials of the ink are mixed and stirred by a high-speed mixer at a speed of 2000 rpm for 1 hour to make them evenly mixed to obtain a graphite nanosheet printing ink; the graphite nanosheet printin...

Embodiment 3

[0046] Composition of graphite nanosheet printing ink:

[0047]

[0048] Graphite nanosheets are prepared by jet cavitation equipment disclosed in Chinese invention patent CN201110190763.3: use graphite and solvent (acetone-water mixed solution, wherein the volume fraction of acetone is 70%) to prepare a graphite mixed solution with a concentration of 15 mg / ml , the graphite mixture was treated at a pressure of 20 MPa for 3 hours and then directly dried to obtain graphite nanosheets. The average thickness of the prepared graphite nanosheets is about 5nm, the maximum thickness is about 15nm, the proportion of sheets with a thickness less than 3.4nm is less than 17%, the average lateral size is about 5 microns, and the largest lateral size is about 8 microns.

[0049] Various raw materials of the ink were mixed and dispersed by a three-roll machine for 15 minutes to obtain a graphite nanosheet printing ink; the graphite nanosheet printing ink was printed on a PET film by scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com