Small punch testing system based on acoustic emission sensor and testing method thereof

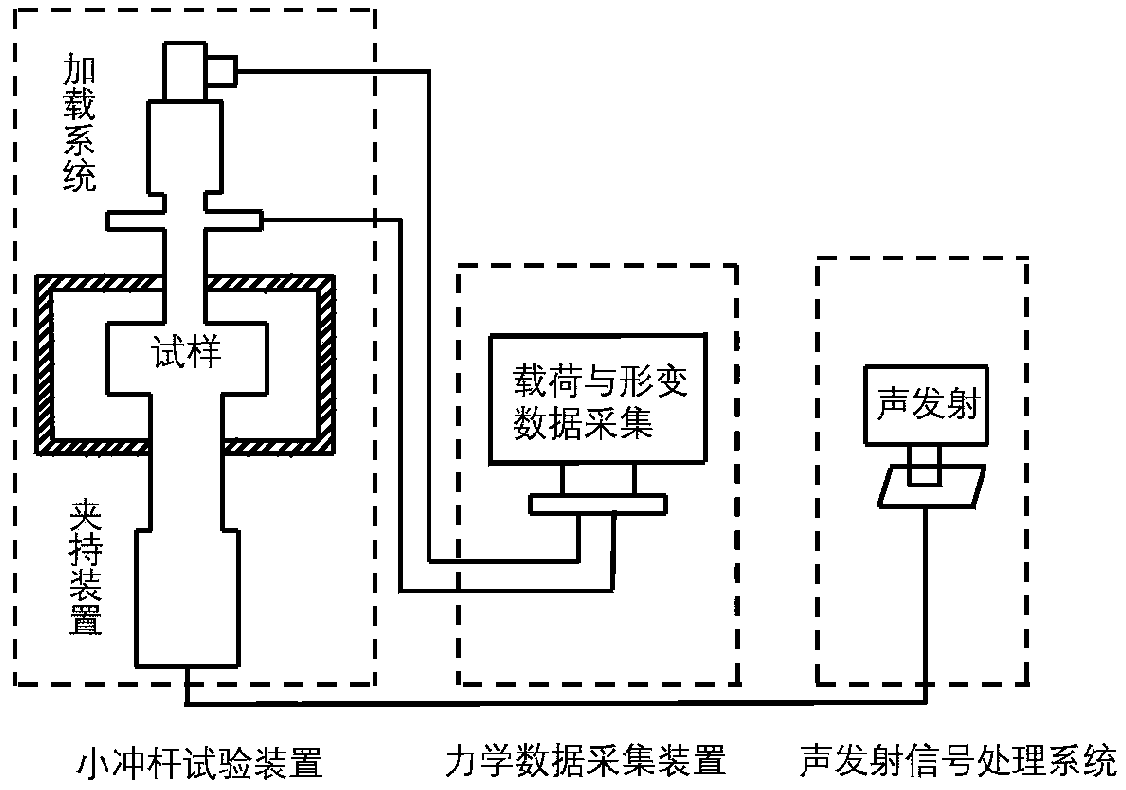

A technology of acoustic emission sensor and test system, which is applied in material analysis using acoustic emission technology, and testing material strength and instrument using stable tension/pressure, which can solve the problem that the deformation of the sample sheet cannot be reflected in real time, and the test data is unreliable. , There is no specific device to monitor the problem of sample flakes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

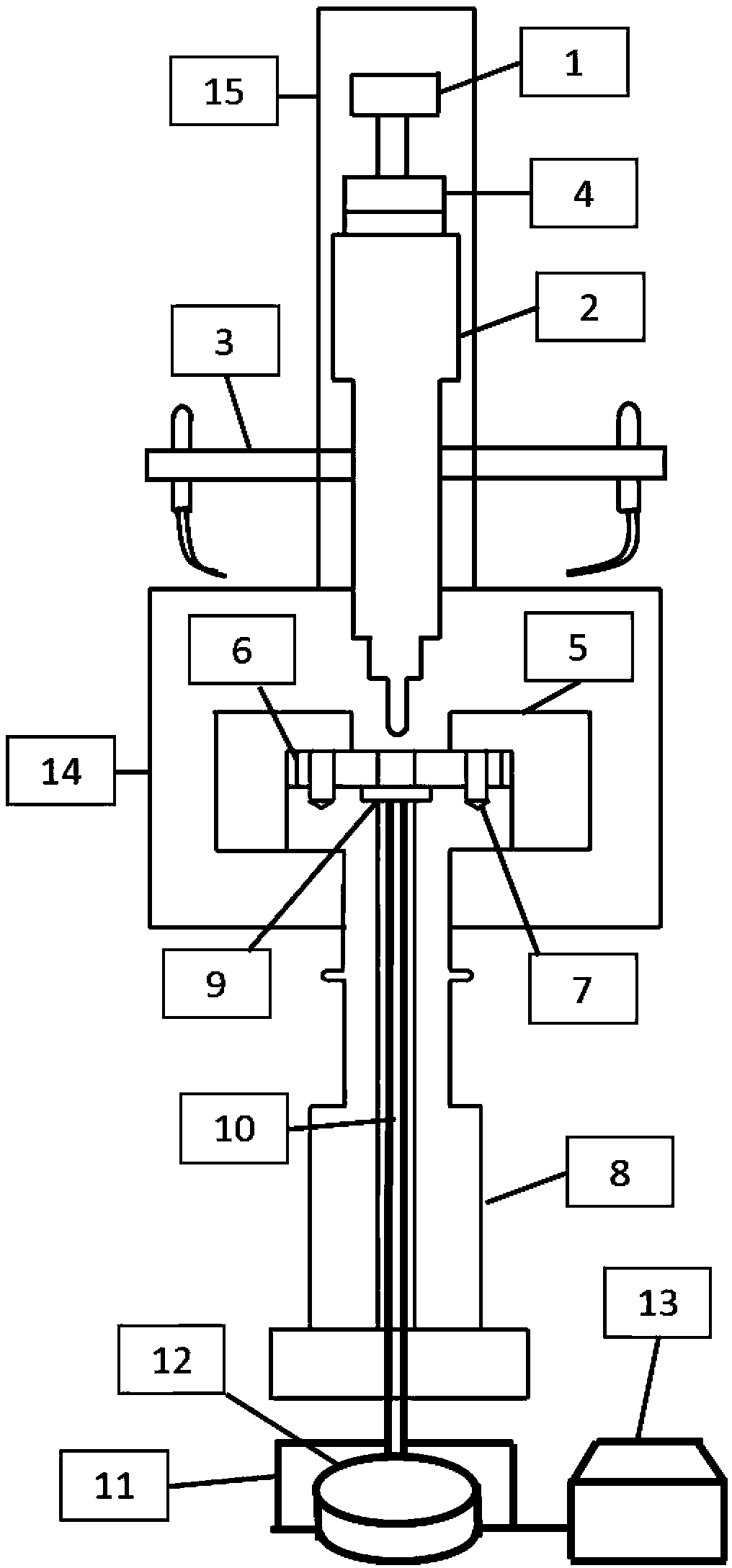

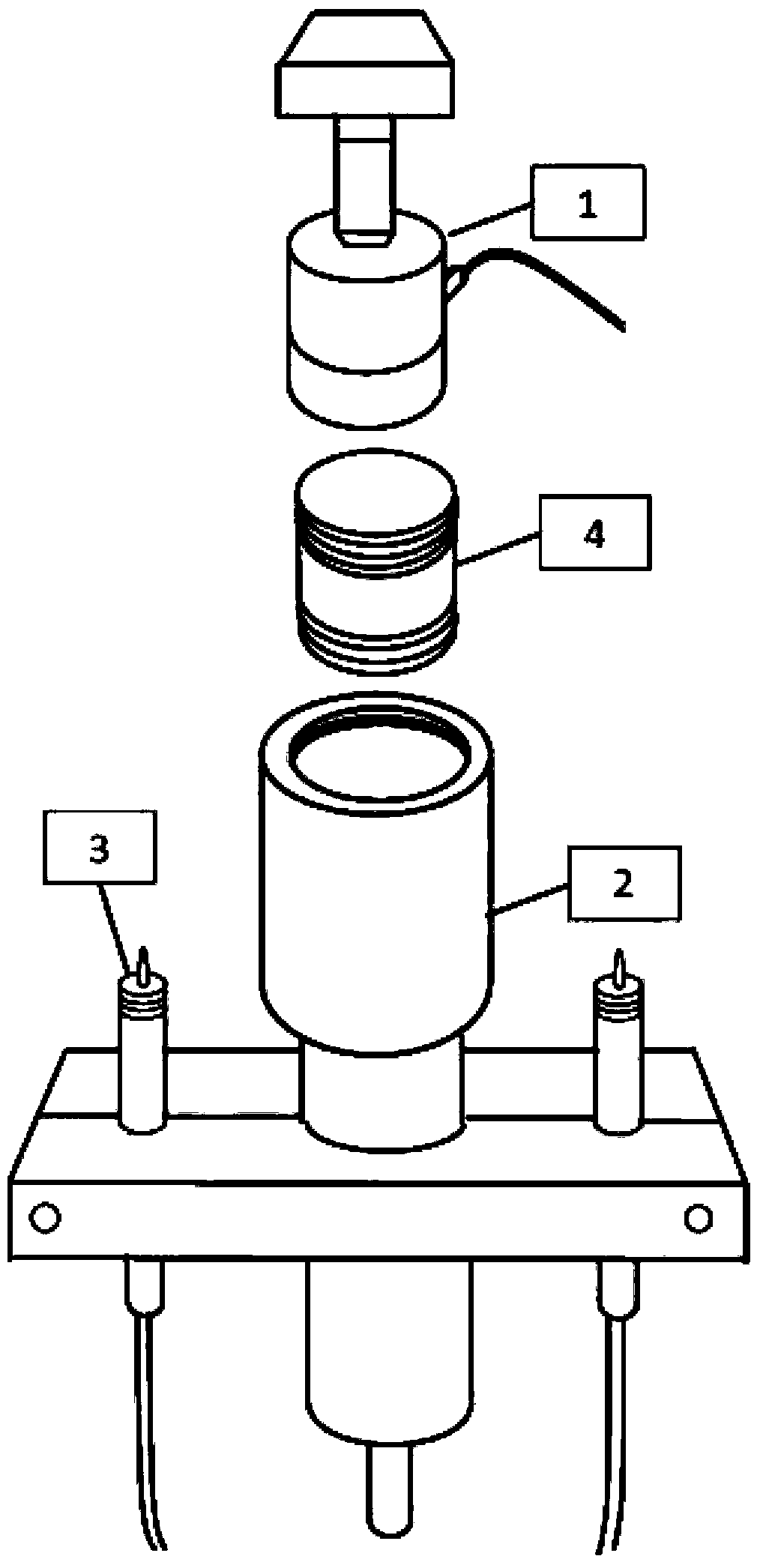

[0021] Embodiment: The loading system mainly includes a load sensor 1 , a punch 2 , a linear variable differential transformer 3 , and a cylindrical connecting rod 4 . The load sensor 1 is used to control the magnitude of the force sensed by the punch, and the load sensor is connected to the cantilever beam 15 in a hydraulic load control manner, which can control both the magnitude of the load and the punching speed. Two linear variable differential transformers 3 are directly connected to the punch 2, and the movement of the punch 2 drives the movement of the linear variable differential transformer 3, which is used to measure the displacement distance of the punch to characterize the deformation of the sample sheet. A cylindrical link 4 connects the load cell 1 to the punch 2 . The clamping device mainly includes an upper nut 5, a chuck 6, a pin 7 and a sample support table 8. In order to avoid oxidation of the punch and the clamping device, they are all made of high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com