Voltage converter, actuator and gas burner

A technology for step-down converters and actuators, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of small airflow, rapid opening and closing of current valves, and can no longer be accurately controlled, and achieves high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

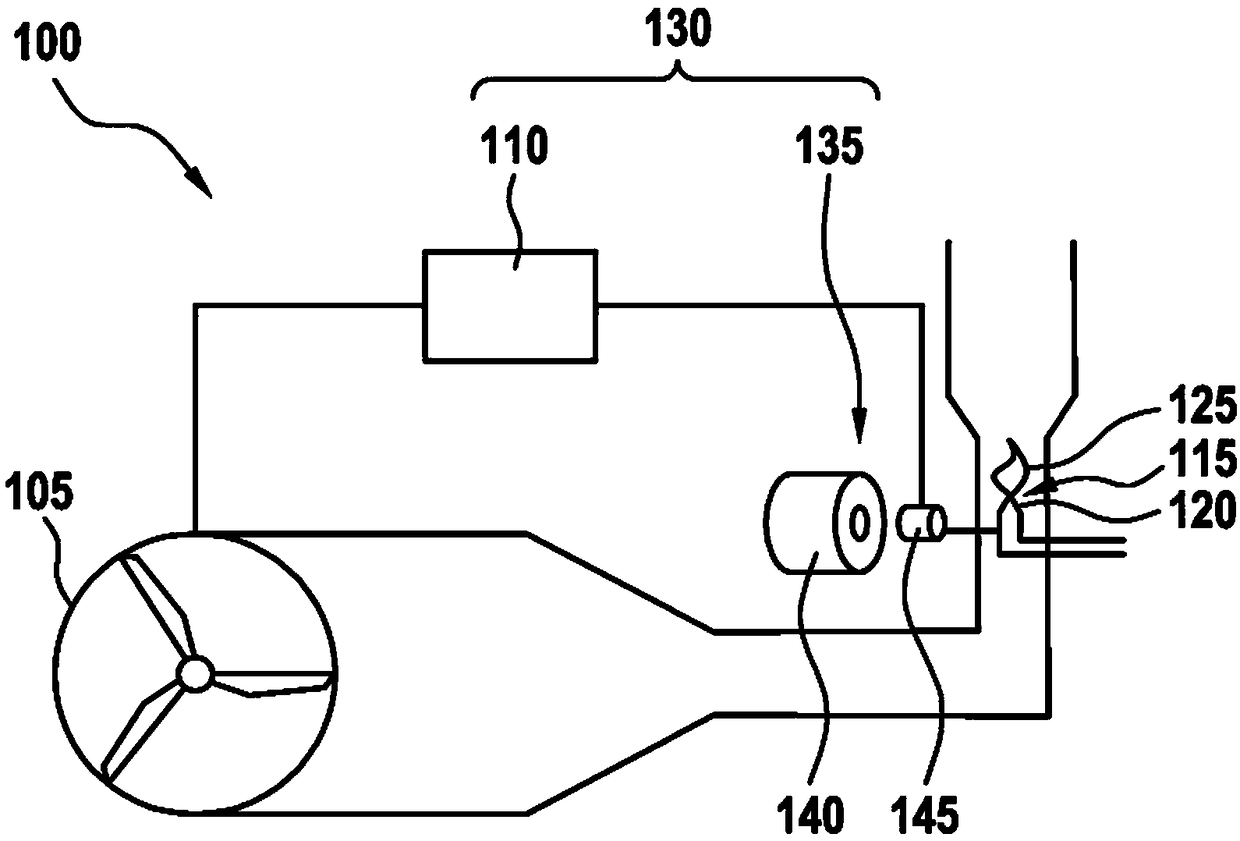

[0018] figure 1 A schematic diagram of the gas burner 100 is shown. Preferably, the gas burner 100 comprises a fan 105 for providing an air volume flow and a control device 110 for controlling the fan 105 . The control device 110 is provided in particular to control the rotational speed of the fan 105 . The volume flow provided by the fan 105 passes through the outlet opening 115 of the gas valve 120 so that the gas discharged from the outlet opening 115 can mix with the air volume flow and can be ignited to form a flame 125 . The flame 125 can be used in particular to heat a liquid, in particular water, for example by means of a heat exchanger. The gas burner 100 can be used in particular in a hot water installation, such as a water heater (Therme). The water heater can be set up to provide hot water in an apartment or house.

[0019] The gas valve 120 is connected with an actuator 130 to open or close the gas valve 120 . Actuator 130 includes a moving coil 135 (also ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com