Cantaloupe powder and preparation method thereof

A technology of cantaloupe and coarse flour, applied in the agricultural field, can solve problems such as poor taste, reduced economic value of sugar content, and failure to obtain consumers, so as to promote development, improve utilization rate, and increase economic income of melon farmers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

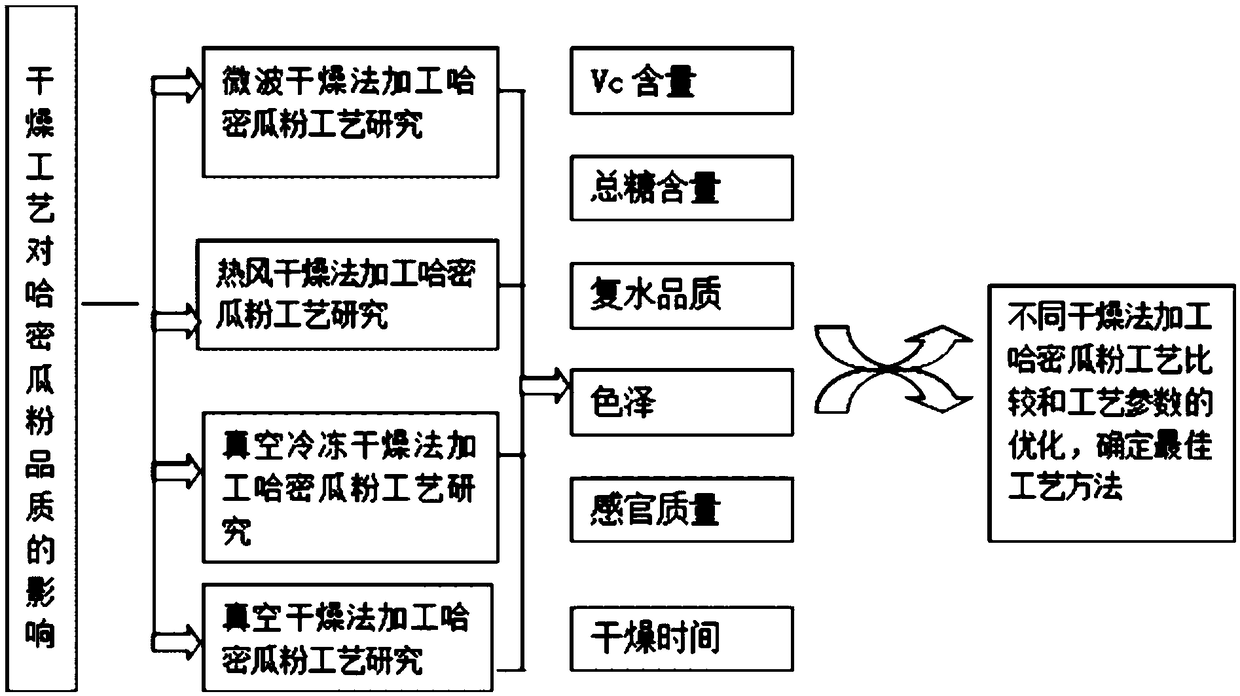

Method used

Image

Examples

Embodiment 1

[0024] Cleaning the residual cantaloupe fruit, cutting it open and removing the seeds, to obtain the pretreated fruit; making the above pretreated fruit into a pulp, squeezing the above pulp to obtain the cantaloupe juice; filtering and clarifying the above cantaloupe juice to obtain the pretreated fruit. Dry the juice; spread the above pre-dried juice in a vacuum freeze-drying oven (DZF-6020 vacuum freeze-drying oven, purchased from Shanghai Shengke Instruments); drying conditions: pre-freezing temperature -40 ° C, sublimation drying of vacuum freeze-drying The time is 40 hours, the analytical drying temperature is 40° C., and the vacuum degree is maintained at 10-30 Pa to obtain cantaloupe coarse powder; the above-mentioned cantaloupe coarse powder is pulverized (DF T-200 pulverizer) and sieved to obtain cantaloupe powder.

Embodiment 2

[0026] Cleaning the residual cantaloupe fruit, cutting it open and removing the seeds, to obtain the pretreated fruit; making the above pretreated fruit into a pulp, squeezing the above pulp to obtain the cantaloupe juice; filtering and clarifying the above cantaloupe juice to obtain the pretreated fruit. Dry the juice; spread the above-mentioned pre-dried juice in a vacuum drying oven (DZF-6050AB vacuum drying oven, purchased from Lichen Technology), set the drying temperature at 30°C, 35°C, 40°C and 45°C in turn, and vacuum degree 50Pa, to obtain cantaloupe powder; the above-mentioned cantaloupe powder is pulverized (DF T-200 pulverizer), sieved, to obtain cantaloupe powder.

Embodiment 3

[0028] Cleaning the residual cantaloupe fruit, cutting it open and removing the seeds, to obtain the pretreated fruit; making the above pretreated fruit into a pulp, squeezing the above pulp to obtain the cantaloupe juice; filtering and clarifying the above cantaloupe juice to obtain the pretreated fruit. Dried juice; The above-mentioned pre-dried juice is tiled in a microwave drying box (adopting EM-L520P microwave oven, purchased from Sanyo / Sanyo), and the drying power is set successively as 180W, 360W, 540W and 720W to obtain the coarse powder of Hami melon; The cantaloupe coarse powder is pulverized (DFT-200 pulverizer) and sieved to obtain cantaloupe powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com