Polymer cement-based waterproof coating and preparing method thereof

A waterproof coating, cement-based technology, used in anti-corrosion coatings, asphalt coatings, coatings, etc., can solve the problems of water-based coatings, such as unsatisfactory long-term water resistance, inability to meet construction requirements, and inability to construct waterproof materials, achieving no need for multi-level waterproof construction. , Shorten the construction period and reduce the effect of waterproofing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present invention provides a polymer cement-based waterproof coating, comprising component A and component B, and the weight ratio of component A to component B is 1:1.5,

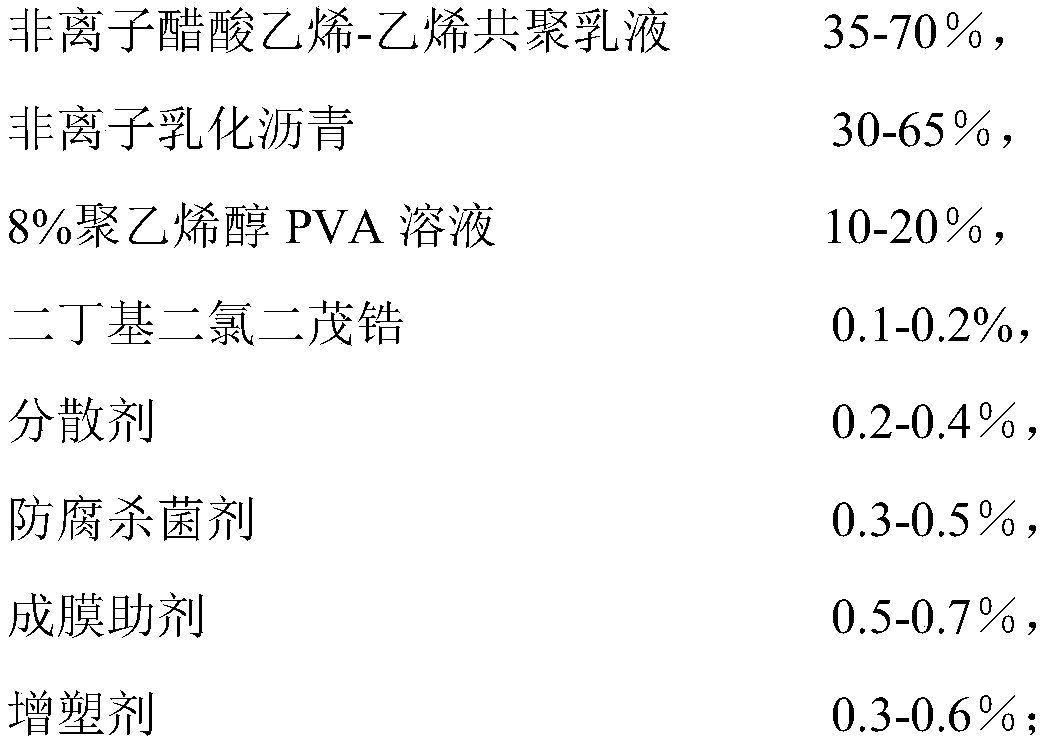

[0031] The A component includes the following components by weight percentage:

[0032]

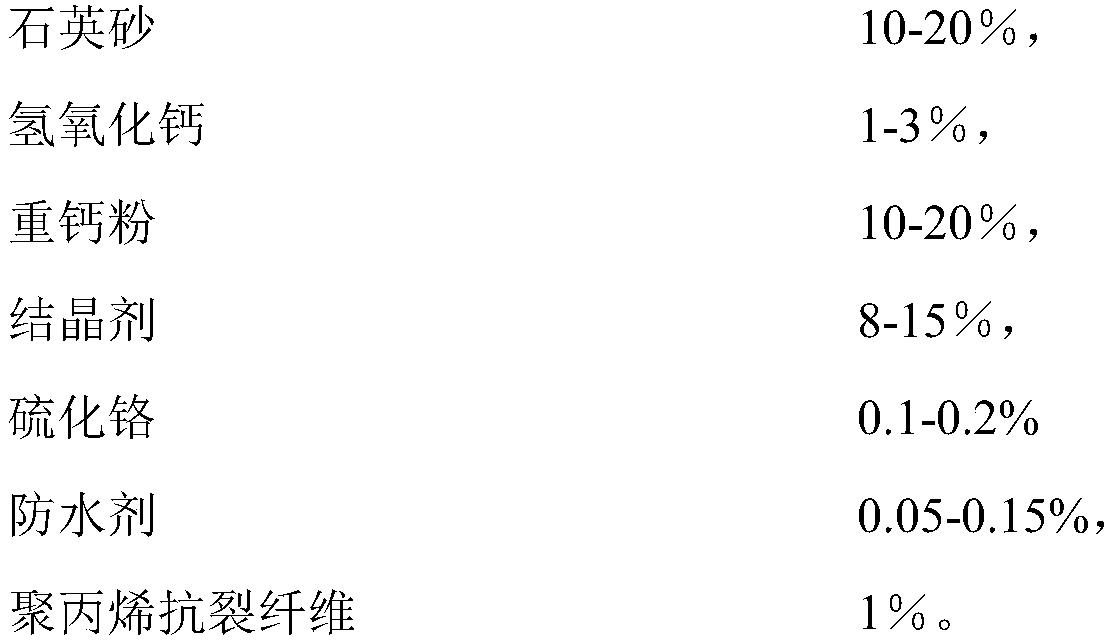

[0033] The B component includes the following components by weight percentage:

[0034]

[0035] Weigh each component according to the above weight percentage, first mix the components of component A uniformly, slowly add the uniform mixture of component B under constant stirring, and continue stirring until the mixing is uniform and there is no clumping in the shape of porridge. The polymer cement-based waterproof coating is obtained.

[0036] The obtained waterproof coating was tested. The test standard refers to GB / T 23445-2009. The results are shown in Table 1.

Embodiment 2

[0038] The present invention provides a polymer cement-based waterproof coating, comprising component A and component B, and the weight ratio of component A to component B is 1:2.5,

[0039] The A component includes the following components by weight percentage:

[0040]

[0041] The B component includes the following components by weight percentage:

[0042]

[0043]

[0044] The preparation method and test method are the same as in Example 1, and the test results are shown in Table 1.

Embodiment 3

[0046] The present invention provides a polymer cement-based waterproof coating, comprising component A and component B, and the weight ratio of component A to component B is 1:1,

[0047] The A component includes the following components by weight percentage:

[0048]

[0049] The B component includes the following components by weight percentage:

[0050]

[0051] The preparation method and test method are the same as in Example 1, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com