A kind of flexible and controllable aromatic adhesive latex film and its preparation method

An adhesive and aromatic technology, which is applied in the field of aromatic adhesive latex film and its preparation, can solve the problems of reducing the utilization rate of essential oils, the volatilization loss of aroma components, and the inability to directly attach to the surface of the fabric, and achieves adjustable mechanical properties and reduced Slow volatilization rate, long-term sustained release effect with obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

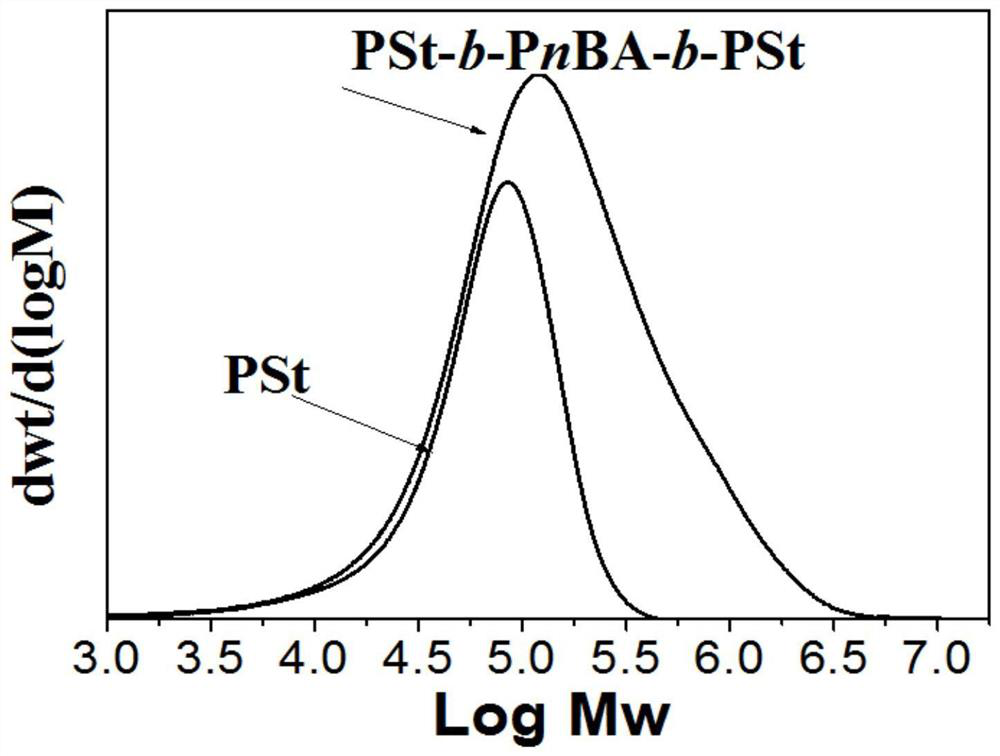

[0044] (1) Synthesis of adhesive latex.

[0045] In this embodiment, the selected structure of the macromolecular trithiocarbonate compound is shown in formula I, wherein, A is shown in formula III, B is shown in formula V, X=3, Y=70.

[0046] According to the formula in Table 1, the sodium lauryl sulfate aqueous solution and the macromolecular trithiocarbonate compound are mixed and stirred to a homogeneous phase to obtain a water system mixed solution; the lavender essential oil, styrene and n-hexadecane are mixed and stirred to a homogeneous phase to obtain a mixed liquid of the oil system. The water, oil system mixture and deionized water are mixed and stirred again, the purpose is to make them fully mixed and uniform to form an initial emulsified dispersion. The initial emulsified dispersion was placed in an ice bath and ultrasonically prepared to obtain a fine emulsified dispersion. Transfer the resulting fine emulsified dispersion to a four-necked flask under a nitrog...

Embodiment 2

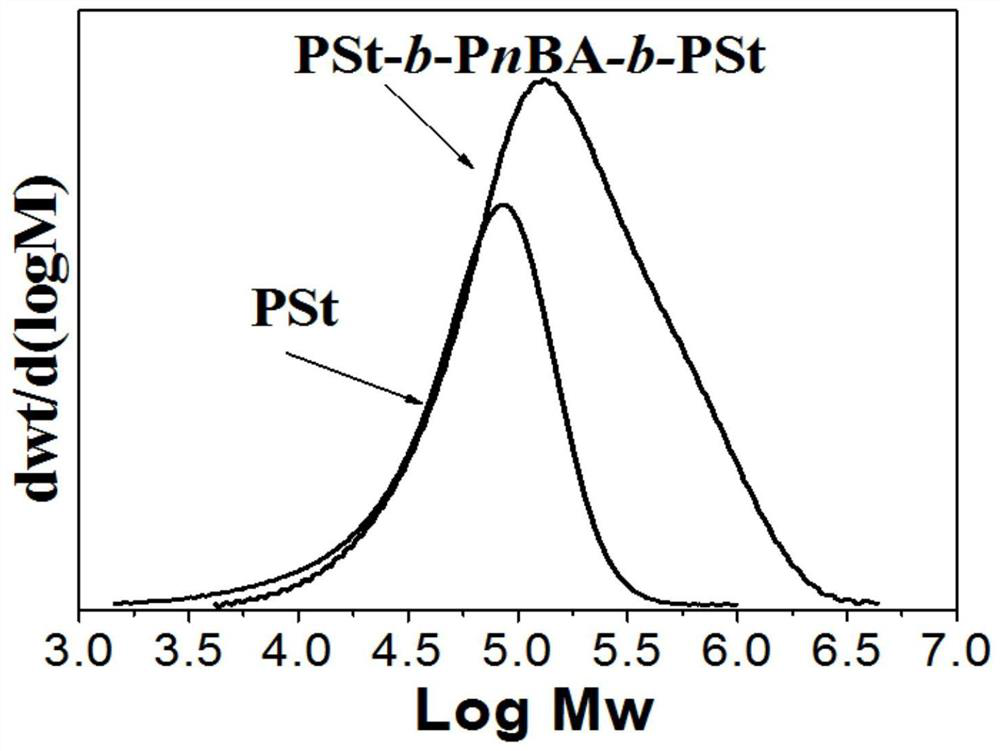

[0052] (1) Synthesis of adhesive latex.

[0053] In this embodiment, the selected structure of the macromolecular trithiocarbonate compound is shown in formula I, wherein, A is shown in formula II, B is shown in formula IV, X=5, Y=30.

[0054]According to the formula in Table 2, the sodium lauryl sulfate aqueous solution and the macromolecular trithiocarbonate compound are mixed and stirred to a homogeneous phase to obtain a water system mixed solution; the olive essential oil, methyl methacrylate and n-hexadecane are mixed Mix and stir until homogeneous to obtain an oily system mixture. The water, oil system mixture and deionized water are mixed and stirred again, the purpose is to make them fully mixed and uniform to form an initial emulsified dispersion. The initial emulsified dispersion was placed in an ice bath and ultrasonically prepared to obtain a fine emulsified dispersion. Transfer the resulting fine emulsified dispersion to a four-necked flask under a nitrogen atm...

Embodiment 3

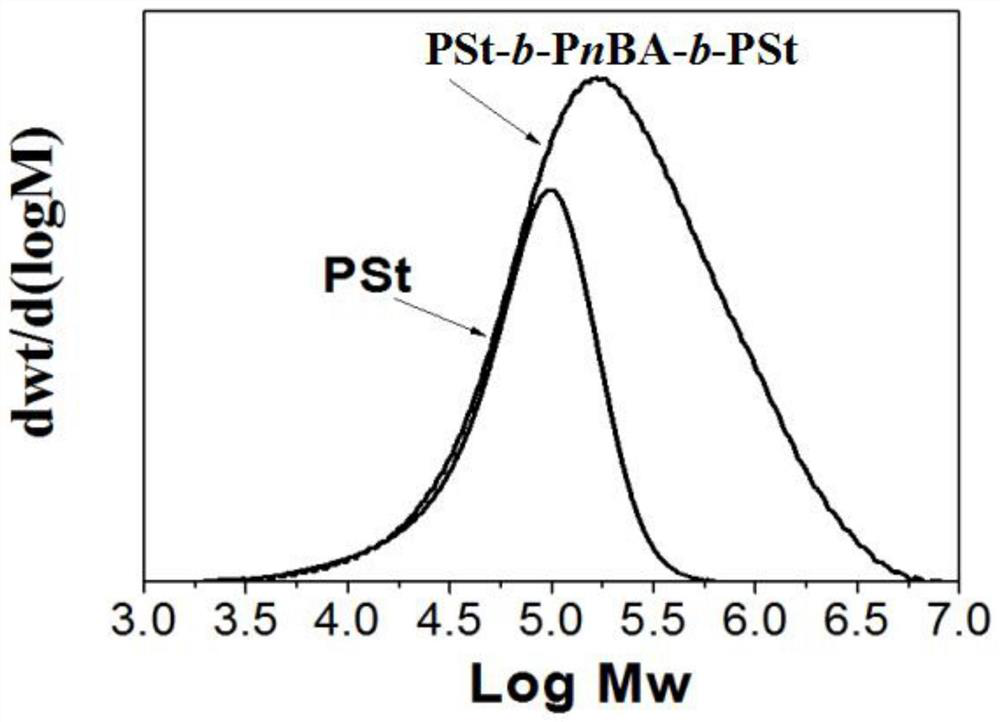

[0060] (1) Synthesis of adhesive latex.

[0061] In this embodiment, the selected structure of the macromolecular trithiocarbonate compound is shown in formula I, wherein, A is shown in formula III, B is shown in formula IV, X=4, Y=40.

[0062] According to the formula in Table 3, the sodium dodecylsulfonate aqueous solution and the macromolecular trithiocarbonate compound were mixed and stirred to a homogeneous phase to obtain a water system mixed solution; the cinnamon essential oil, styrene and n-hexadecane were mixed and Stir until homogeneous to obtain an oily system mixture. The water, oil system mixture and deionized water are mixed and stirred again, the purpose is to make them fully mixed and uniform to form an initial emulsified dispersion. The initial emulsified dispersion was placed in an ice bath and ultrasonically prepared to obtain a fine emulsified dispersion. Transfer the resulting fine emulsified dispersion to a four-necked flask under nitrogen atmosphere. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com